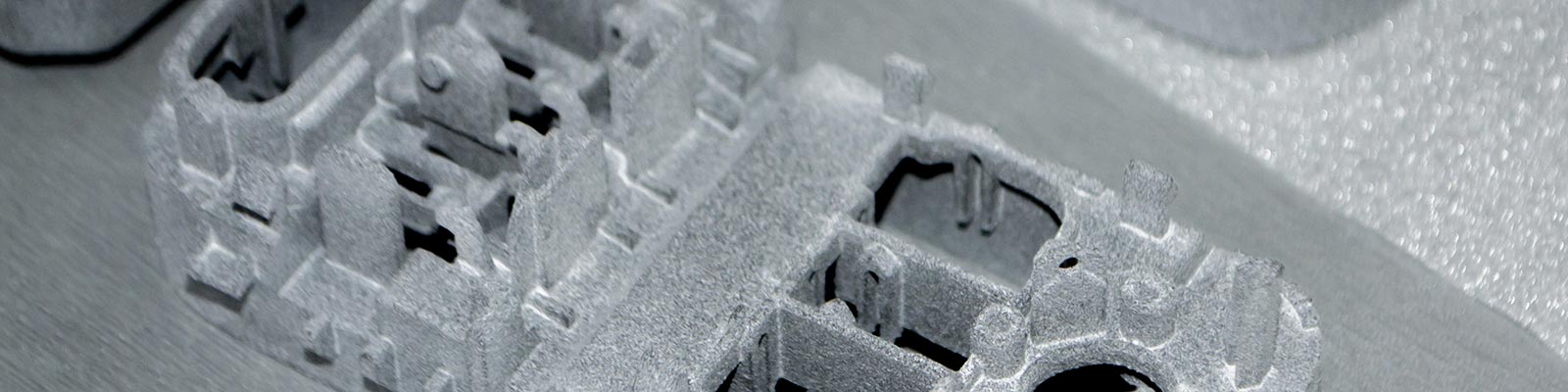

SLS PA 11 is high-temperature resistant, has good toughness and high strength, and is suitable for functional use. It does not require support when printing and is suitable for prototyping products with extremely complex structures.

Please check the mechanical properties chart of SLS Nylon PA 11.

| Parameter | Method | Result |

| Heat deformation (0.46 MPa) | GB/T 1634.2-2004 | 151.1℃ |

| Heat deformation (1.82 MPa) | GB/T 1634.2-2004 | 51℃ |

| Melting point | GB/T 19466.1-2004 | 201 ℃ |

| Tensile strength | GB/T 1040.2-2006 | 48 MPa |

| Tensile modulus | GB/T 1040.2-2006 | 1483 MPa |

| Elongation at Break | GB/T 1040.2-2006 | 56% |

| Flexural strength | GB/T 9341-2008 | 59 MPa |

| Flexural modulus | GB/T 9341-2008 | 1470 MPa |

| Notched impact strength | GB/T 1843-2008 | 26 KJ/㎡ |

| Unnotched impact strength | N/A | N/A |