What is frosting?

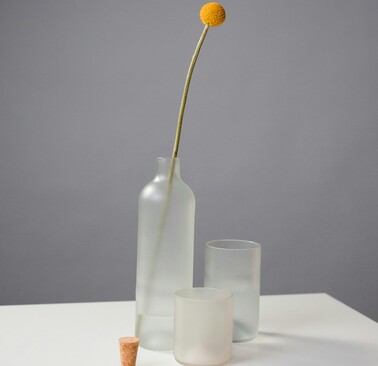

Frosting in 3D printing refers to the process of creating a matte surface effect on 3D printed parts, especially those manufactured using SLA (stereolithography) technology.

Frosting involves subtly altering the surface texture to reduce gloss and enhance the overall aesthetic by giving the part a smooth, non-reflective appearance.

Frosting is achieved through fine sanding and is often used to eliminate visible layer lines and give 3D printed objects a more professional, refined look.