Info Coming Soon

180*180*200mm

Info Coming Soon

Info Coming Soon

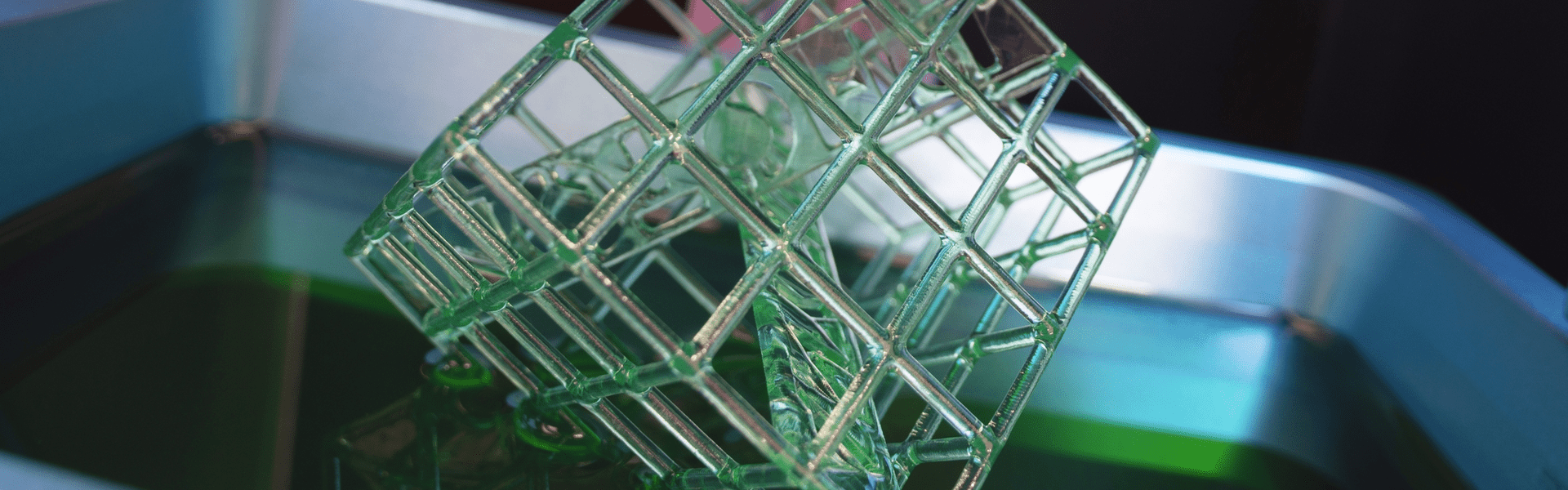

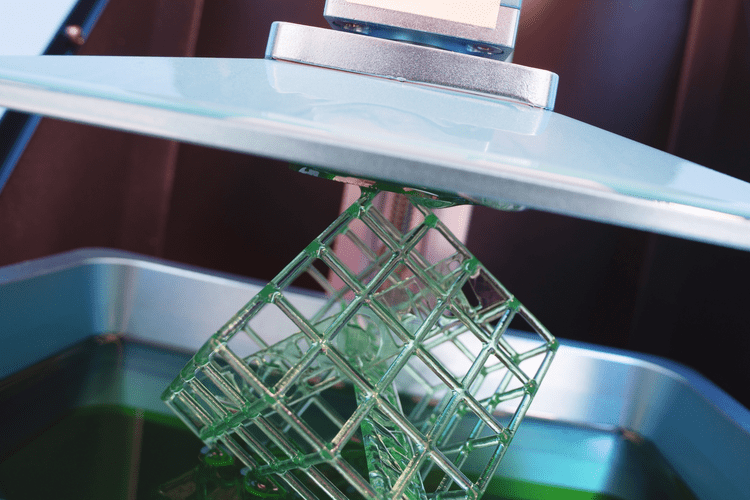

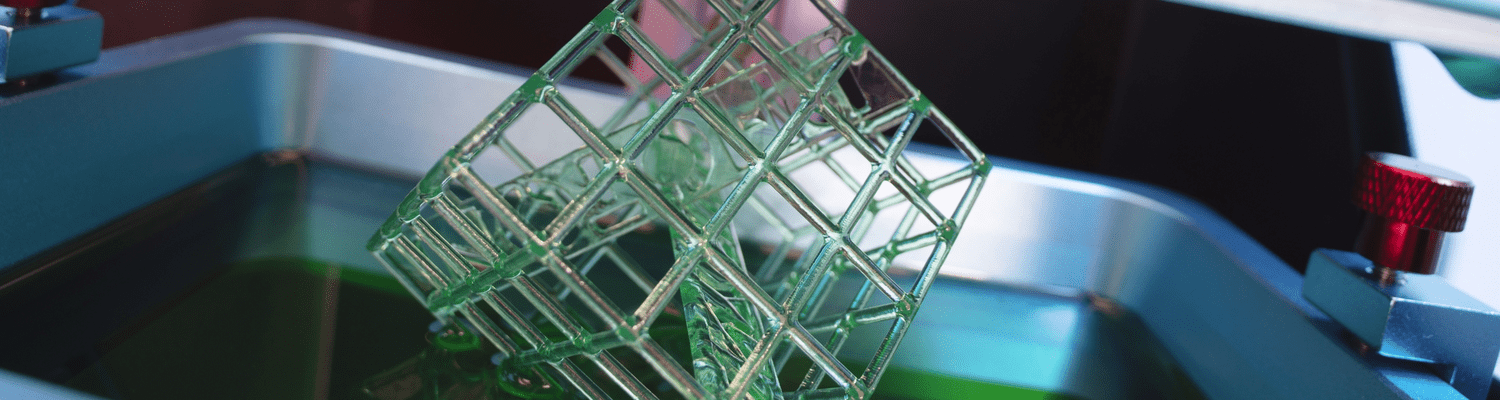

Digital light processing (DLP 3D printing) uses a projector to shine light onto the photosensitive resin layer by layer to create a product. This light cures the resin in the same way that the laser does in SLA printing, but instead of a single laser, DLP printers use a digital micromirror device (DMD) to project the image onto the resin. DLP is probably the fastest resin-based 3D Printing technology currently, and it is ideal for rapid prototyping.

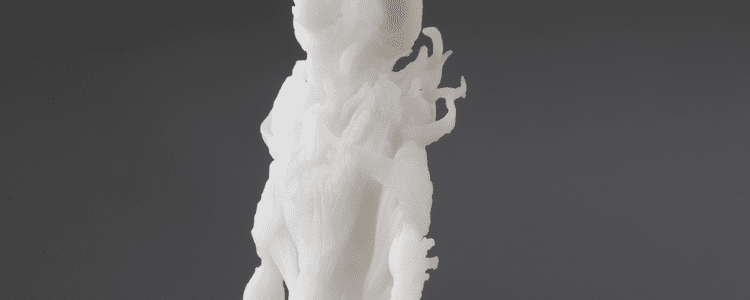

DLP 3D printing is widely used in a variety of applications, including prototyping, art, sculpture, jewelry making, dental and orthopedic models, surgical guides, and custom implants.

Digital light processing uses light to cure liquid resin into solid objects. Here are what we do for DLP 3D printing processes at 3DSPRO:

Import files on the DLP 3D printers.

Import files on the DLP 3D printers. Optimize build chamber space.

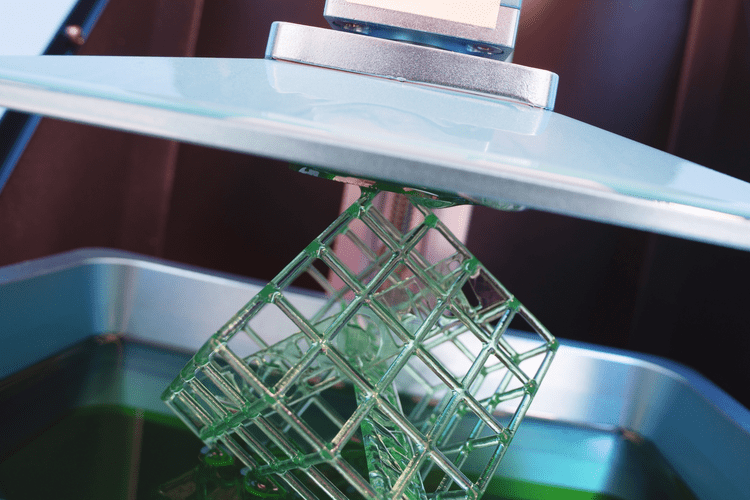

Optimize build chamber space. DLP 3D printers operating.

DLP 3D printers operating. Take the DLP 3D printed part out of the build chamber.

Take the DLP 3D printed part out of the build chamber. Washing the resin 3D prints.

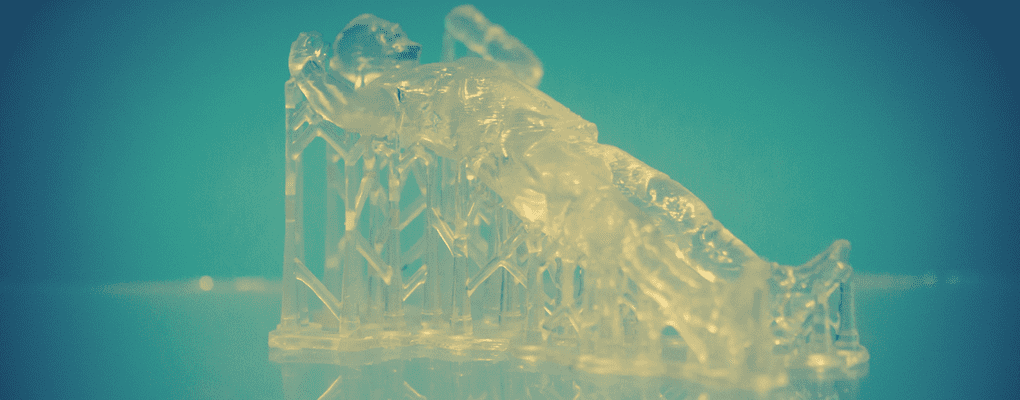

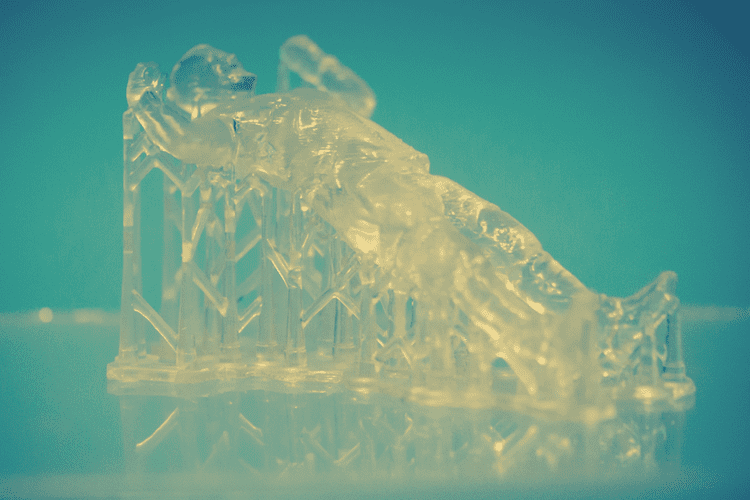

Washing the resin 3D prints. Supports removal.

Supports removal. UV curing resin parts.

UV curing resin parts. Send DLP printed parts to further post-processing (optional).

Send DLP printed parts to further post-processing (optional). Quality inspection.

Quality inspection. Packing and shipping.

Packing and shipping.

1. When it comes to resin-based printing, DLP printers can print much faster than SLA printers because the entire layer is cured at once.

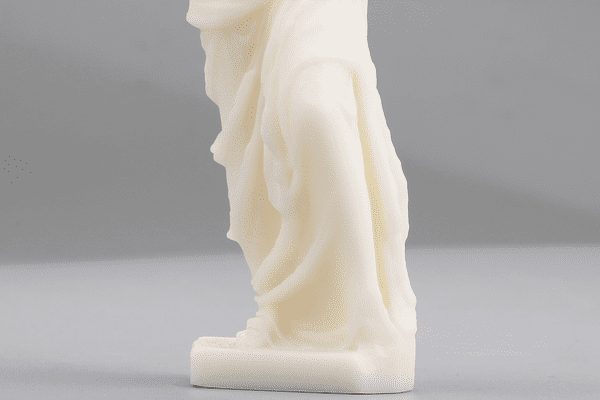

2. DLP produces parts with fine details and high precision, ideal for intricate designs.

3. DLP parts typically have a smooth surface finish.

1. DLP printers are often limited to using only certain types of resin.

2. DLP printed parts are generally less durable and have lower tensile strength compared to other 3D printing methods.

3. DLP prints are sensitive to UV light. They can be degraded if exposed to direct sunlight or other UV light sources for extended periods.

4. Require supports.

5. Print resolution decreases with distance from the light source, affecting the quality of larger prints.

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept