48 Hours/72 Hours

1700*800*600mm

± 200μm or 0.2%mm

150

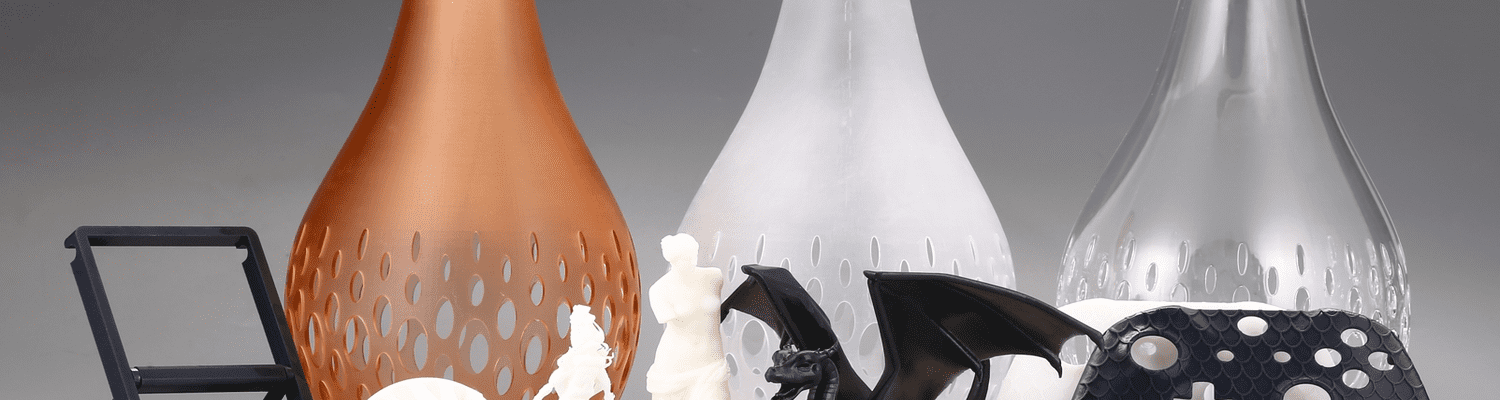

Stereolithography (SLA 3D printing) cured liquid resins by a focused light source, typically a laser or UV light. The resin is contained in a tank, and a build platform is submerged in the resin. The light source is then used to selectively harden the resin, layer by layer, until the desired shape is achieved.

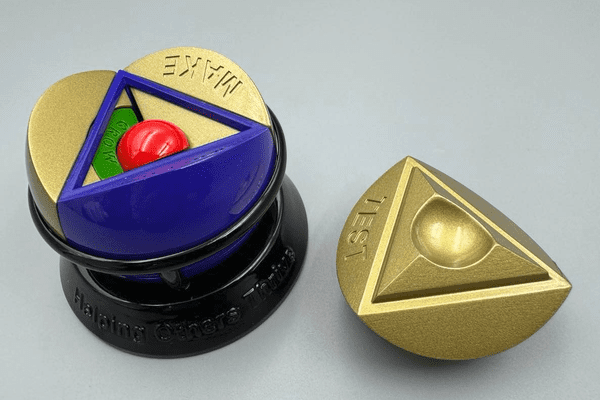

SLA printing is widely used in industries such as consumer products, art and design, and medical devices and is increasingly accessible to hobbyists and makers. SLA can produce prototypes that closely resemble the final product, and SLA printing simplifies the prototyping process by producing parts with smooth surfaces that are easy to paint.

Stereolithography uses a high-energy UV laser to cure liquid resin into solid plastic. Here are what we do for SLA 3D printing processes at 3DSPRO:

Import files on the SLA 3D printers.

Import files on the SLA 3D printers. Optimize build chamber space.

Optimize build chamber space. SLA 3D printers operating.

SLA 3D printers operating. Take the SLA 3D printed part out of the build chamber.

Take the SLA 3D printed part out of the build chamber. Washing the resin 3D prints.

Washing the resin 3D prints. Supports removal.

Supports removal. UV curing resin parts.

UV curing resin parts. Send SLA printed parts to further post-processing (optional).

Send SLA printed parts to further post-processing (optional). Quality inspection.

Quality inspection. Packing and shipping.

Packing and shipping.

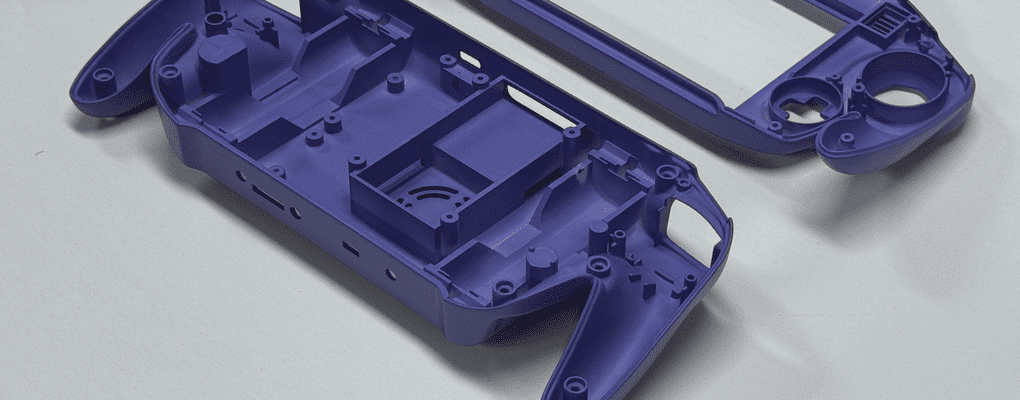

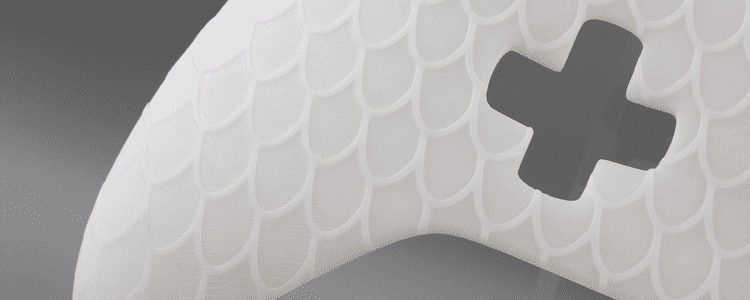

1. Create complex internal and external geometries, such as hollow parts, hollow-out structures, lattice structures, etc.

2. Capable of producing large parts.

3. Produces parts with exceptional accuracy and fine details, making it ideal for intricate designs and prototypes.

4. Resin 3D printed parts have a smooth and glossy surface finish, often requiring minimal post-processing.

5. Support a variety of resins, including standard, transparent, and high-definition resins, allowing for diverse applications.

1. SLA printed parts may face yellowing when exposed to sunlight over time.

2. SLA parts can be more brittle compared to those produced by other 3D printing methods, limiting their use in applications requiring high strength.

3. Require supports.

4. Require extensive post-processing, including washing, UV curing, and sanding, to achieve the desired finish.

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept