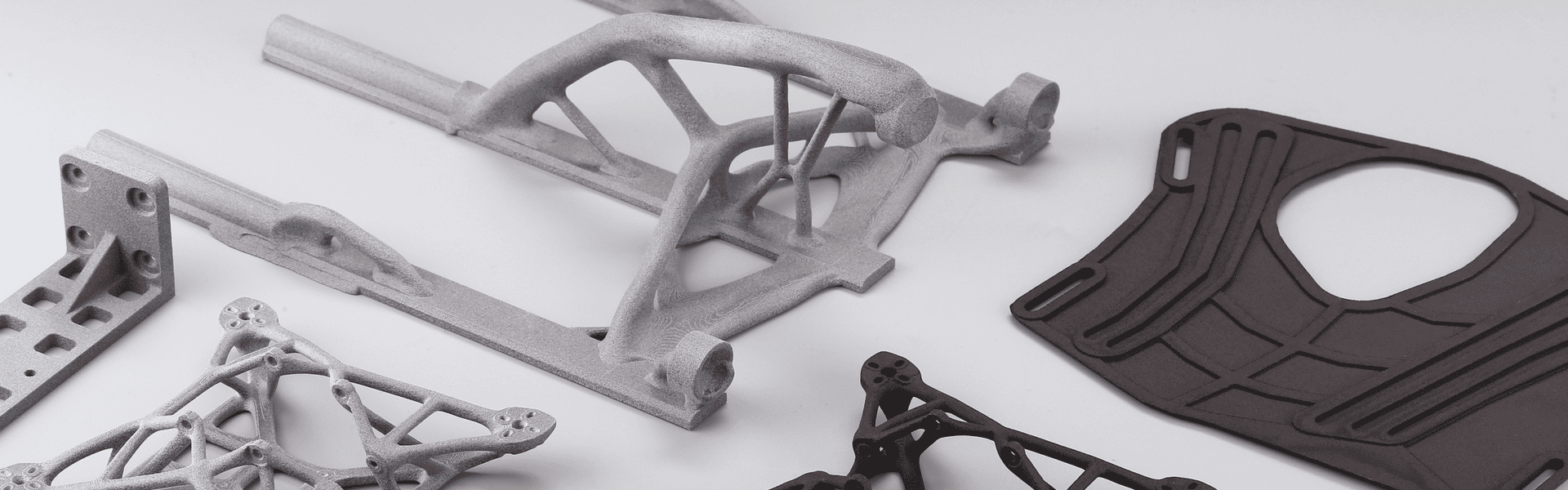

Nylon, also known as polyamide (PA), is a versatile and durable synthetic polymer. Nylon 3D printing creates strong and functional parts using Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) at 3DSPRO. Nylon 3D prints are used in producing functional prototypes, end-use parts, gears, hinges, machine parts, and snap-fit components.

Nylon PA 6 CF Black is a carbon fiber–reinforced nylon material that is compatible with selective laser sintering. It combines the toughness and wear resistance of PA 6 with the strength and rigidity of carbon fiber. Maximum printing size is 350*350*400mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.45 MPa)

Notched Impact Strength

Unnotched Impact Strength

Nylon PA 6 Glass-filled Black offers excellent rigidity, heat resistance, and corrosion resistance, making it suitable for functional parts verification and small-scale production. Maximum printing size is 350*350*400mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.45 MPa)

Notched Impact Strength

Unnotched Impact Strength

Nylon PA 11 Black is an eco-friendly polyamide with great mechanical properties, making it ideal for functional parts such as gears, drone components and technical parts in high-stress environments. Maximum printing size is 300*200*280mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.46 MPa)

Notched Impact Strength

Unnotched Impact Strength

Nylon PA 11 Gray Black is an eco-friendly polyamide that can produce strong, detailed parts suitable for automotive components, prosthetics, sports equipment, and mechanical parts like hinges and snap-fits. Maximum printing size is 380*380*284mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Elongation at Yield

Impact Strength

HP® High Reusability PA 12. Nylon PA 12 Gray produces detailed and durable parts with a slightly grainy finish, ideal for functional prototypes and end-use components like housings, enclosures, fixtures, snap fits, and hinges. Maximum printing size is 380*380*284mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Melting Point

Heat Deformation (0.45 MPa)

Heat Deformation (1.8 MPa)

Density

Nylon PA 12 Black is a high-performance polyamide that can produce detailed and durable parts ideal for functional prototypes and end-use components like housings, enclosures, fixtures, snap fits, and hinges. Maximum printing size is 350*350*500mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.45 MPa)

Notched Impact Strength

Unnotched Impact Strength

Nylon PA 12 White produces detailed and robust parts ideal for functional prototypes and end-use components like jigs, fixtures, gears, and bearings. Maximum printing size is 360*560*660mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.46 MPa)

Notched Impact Strength

Unnotched Impact Strength

Nylon PA 12 Glass-filled White offers enhanced mechanical properties such as increased strength, rigidity, and dimensional stability, along with improved wear resistance and reduced warping. Maximum printing size is 350*350*400mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.46 MPa)

Heat Deformation (1.82 MPa)

Melting Point

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept