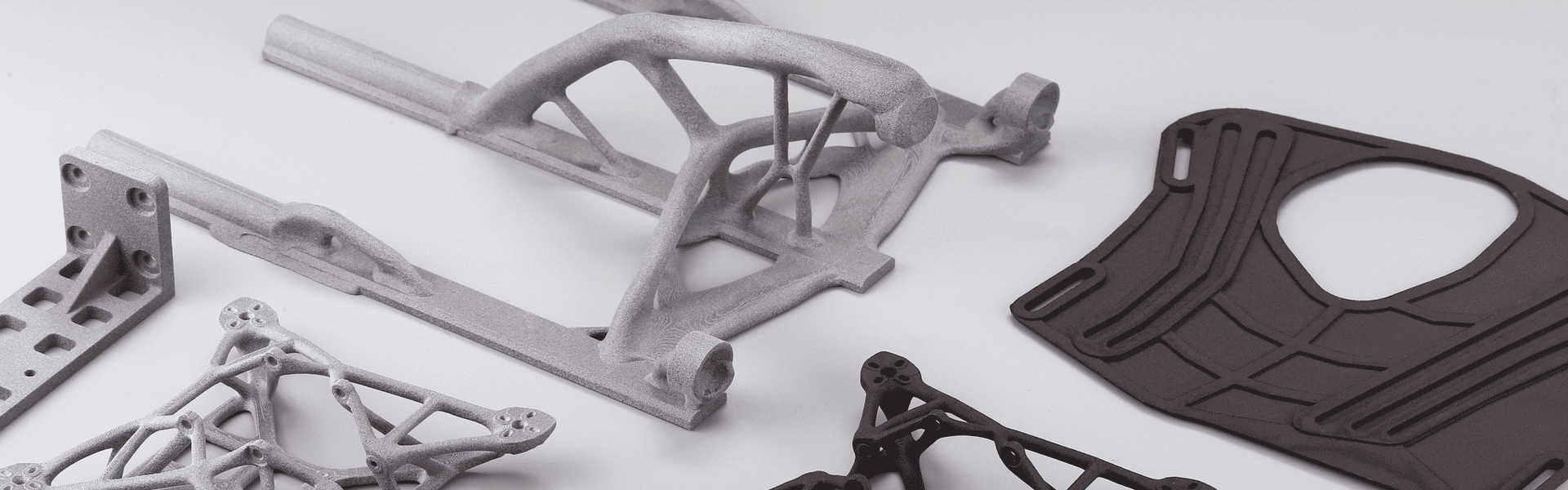

Polypropylene 3D Printing creates lightweight and chemically resistant parts from polypropylene (PP) using Selective Laser Sintering (SLS) method. 3D printed polypropylene is widely used in the automotive, medical, consumer goods, and packaging industries to produce durable and flexible parts such as fluid reservoirs, medical containers, living hinges, and food-safe packaging.

Polypropylene (PP) is a thermoplastic polymer used in a wide variety of applications. SLS 3D printed PP GF parts have excellent mechanical properties, making PP GF the right material if you plan to make waterproof parts. Maximum printing size is 350*350*400mm.

Technology

Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Heat Deformation (0.46 MPa)

Notched Impact Strength

Unnotched Impact Strength

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept