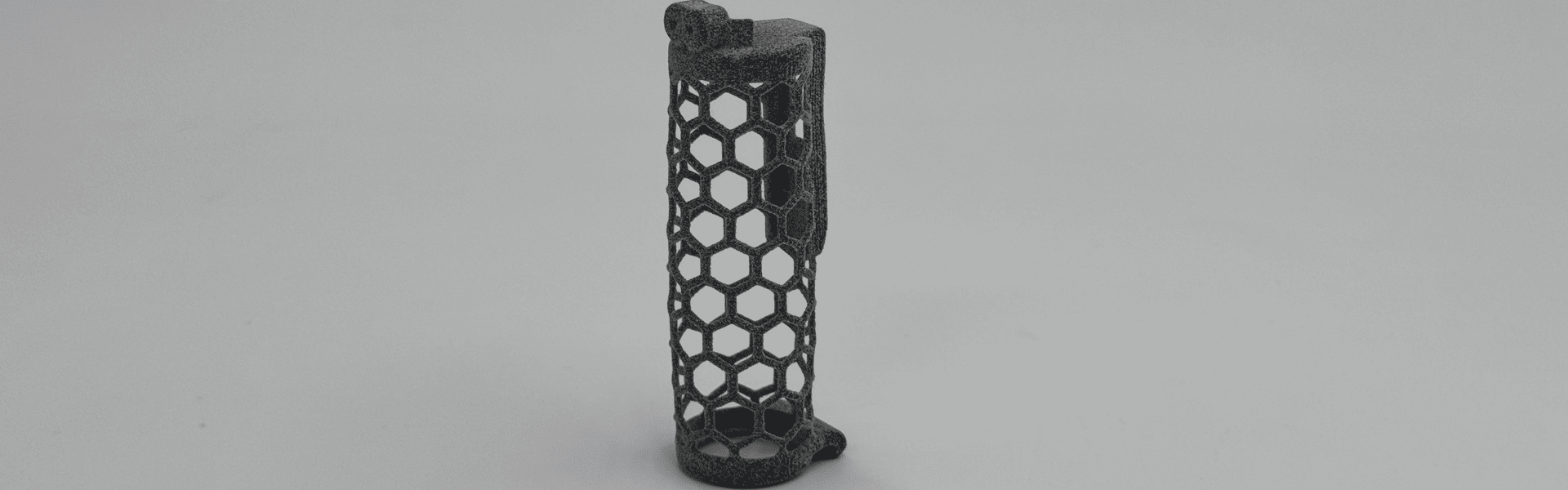

TPU 3D Printing creates flexible and durable parts from thermoplastic polyurethane (TPU) on the 3DSPRO using Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) methods. 3D printed TPU is widely used in the automotive, medical, consumer goods, and sporting goods industries to produce impact-resistant and resilient parts such as gaskets, seals, protective covers, and custom footwear.

TPU Gray is compatible with 3DSPRO's MJF 3D printing. MJF 3D printing of TPU involves layering TPU powder and using fusing and detailing agents to create flexible, durable parts with high precision and smooth surface finish. Maximum printing size is 380*380*284mm.

Technology

Tensile Strength

Elongation at Break

Hardness

Tear Strength (Propagation, Trouser)

Tear Strength (Initiation, Graves)

Rebound Resilience

Abrasion Resistance

Rubber Deterioration

TPU White is compatible with 3DSPRO's SLS 3D printing. SLS 3D printed TPU uses a laser to sinter powdered TPU material, which is then fused layer by layer to create a flexible and durable part. Maximum printing size is 380*380*284mm.

Technology

Tensile Strength

Elongation at Break

Hardness

Melting Point

Density

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept