Paris 2024 Paralympics

The Paris 2024 Paralympic Games, scheduled from 28 August to 8 September 2024, will mark the first time France hosts the summer Paralympics. Featuring around 4,400 athletes competing in 549 medal events across 22 sports, the Games will take place at iconic Parisian landmarks such as the Eiffel Tower, Chateau de Versailles, and Grand Palais, promising a historic and inspiring celebration of athletic excellence and inclusivity.

Image Source: International Paralympic Committee

Real Examples of 3D Printed Prosthetics in the Paralympics

3D Printed Polycarbonate Prosthetic Leg

German cyclist Denise Schindler made history at the Rio 2016 Paralympics by competing with a 3D-printed polycarbonate prosthetic leg. This custom-designed prosthetic, created using Autodesk Fusion 360 software, allowed for rapid adjustments and optimization, helping her win a silver medal in the time trial and a bronze in the road race. (Resource from 3D Printing Industry)

Custom Gloves

British triathlete Joe Townsend and US track athlete Arielle Rausin have utilized 3D printing to create personalized gloves for wheelchair racing. These gloves are tailored to fit their hands perfectly and can be printed in different materials for various conditions, enhancing their performance and comfort. (Resource from The Conversation)

HealTec

In the Middle East, companies like Saudi Arabia’s HealTec are leveraging 3D printing to produce high-quality, affordable prosthetics tailored to the unique needs of local athletes. This initiative has significantly improved accessibility and performance for Arab Paralympians. (Resource from WIRED)

The Impact of 3D Printed Prosthetics on the Paralympics

Customization and Precision

One of the most significant advantages of 3D printing is its ability to create perfectly fitting prosthetic limbs. Traditional prosthetics often require a lengthy and expensive process to achieve a custom fit. In contrast, 3D printing uses digital scans of an athlete’s limb to create a prosthetic that matches their exact dimensions. 3D printing ensures that prosthetics are comfortable and fully functional, allowing athletes to perform at their best.

Cost-Effectiveness and Accessibility

3D printing is also making prosthetics more affordable and accessible. Traditional custom prosthetics are prohibitively expensive, limiting their use by many athletes. However, 3D printing reduces production costs and time, making high-quality prosthetics accessible to a wider range of athletes and helping to level the playing field so more athletes can compete using the best equipment.

Rapid Prototyping and Iteration

The ability to quickly prototype and iterate designs is another key benefit of 3D printing. Athletes and their teams can try different designs and materials and make adjustments based on performance data and feedback. The iterative process allows for continuous improvement and optimization of the prosthesis. For example, prosthetic limbs used by athletes can be adjusted for better aerodynamics, weight distribution, and comfort.

Enhanced Performance and Comfort

Customized 3D printed prosthetic limbs not only fit better, but can also improve athletic performance. For example, 3D printed prosthetic blades designed for runners could provide optimal energy return and stability, improving their running efficiency and speed. Likewise, 3D printed wheelchairs can be tailored to an athlete’s physical and sport-specific needs, providing improved mobility and comfort.

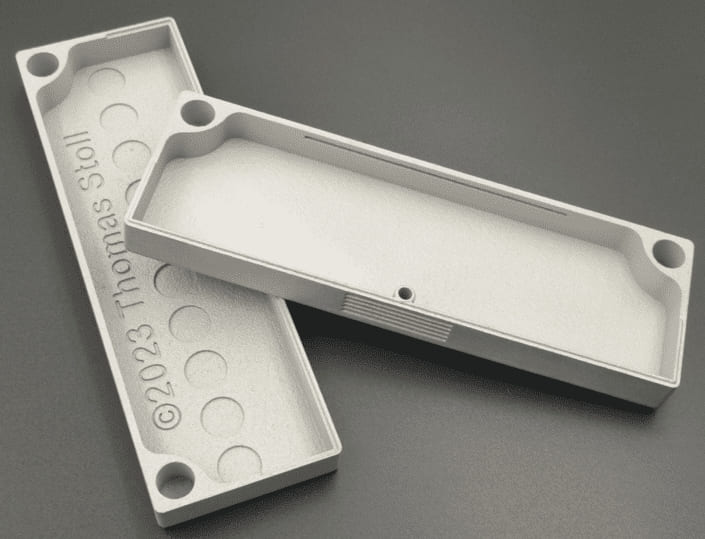

Image Source: nTop