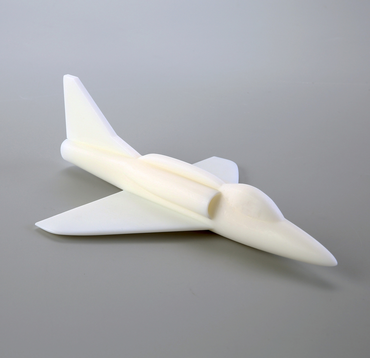

Multiple Color Options

PANTONE® supported.

*The picture color may vary due to shooting light and monitor.

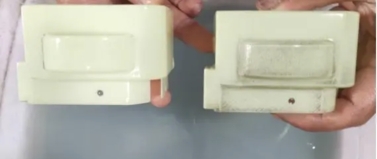

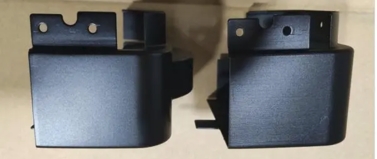

Surface Finishing: Spray Painting

Surface Finishing: Spray Painting

Spray painting not only offers a vibrant, multicolor display but also fully showcases the original design’s details. With spray painting, you can apply different colors to various parts of your 3D prints, adding both visual appeal and functional benefits. It’s compatible with SLA, SLS, and SLM, making it a versatile choice for a wide range of applications.

Spray painting in 3D printing is a post-processing technique used to enhance the appearance of printed objects.

It involves applying paint to the surface of a 3D-printed part to add color, improve the surface finish, and sometimes protect the part.

The goal of spray painting is to achieve a smooth, even finish that hides the layer lines typical of 3D-printed objects, giving them a more professional, high-quality, and aesthetic appearance.

1. Spray painting can significantly improve the visual appeal of a 3D-printed part by adding vibrant colors, gloss, and texture.

2. A layer of paint can protect the 3D-printed object from environmental factors such as corrosion, abrasion, and UV rays.

3. It can be applied to various types of 3D printing materials, including plastics, metals, ceramics, and composites.

4. Compared to other finishing methods, spray painting is relatively low-cost and does not require expensive equipment.

Begin with coarse sandpaper to remove larger imperfections, then progress to finer grits for a smooth finish.

Wipe down the part to eliminate dust and oils, ensuring a clean surface for primer adherence.

Apply the paint in thin, even layers, allowing each coat to dry before adding the next.

Beyond a broad color palette, various paint finishes are also available.

A high gloss finish. Has a reflective sheen similar to a mirror. Any deviation will harm visual appeal and make the surface susceptible to scratches. It’s crucial to apply glossy paint evenly to maintain its aesthetic allure and minimize the risk of surface imperfections.

Gloss paint is widely used to enhance the aesthetic appeal of smart hardware, home appliances, and plastic components, etc.

Featuring a pleasant touch and sturdy surface texture, it is highly resistant to wear and scratches.

Matte paint is widely used in various industries, such as consumer goods, smart hardware, and plastic components, etc.

Rubber-painted products feature a unique softness, silky smoothness, and fine texture with a rubbery feel similar to human skin. They have strong adhesion, impact resistance, and self-healing properties. The paint film is uniformly smooth and chemically resistant, effectively concealing any surface blemishes.

Communication devices, audio-visual products, digital gadgets, car armrests, automobile interior decorations, and electrical appliance casings.

It has a metal-like texture and is wear-resistant and non-stick, effectively preventing metallic oxidation that occurs in some paints.

Automobile bodies, digital product casings, and other mirror-like metals, achieving an effect similar to electroplating.

Due to the shrinking action of the shrinkage agent, the leather texture effect can be self-generated.

Automobile interiors and the exterior surfaces of plastic and metal products.

The shrinking action of the agent naturally creates a crackled effect. The crackle texture is uniform, diverse, and artfully arranged, offering a rich three-dimensional aesthetic.

The exterior surfaces of plastic and metal products.

Gloss UV varnish is a transparent coating, also known as UV lacquer. Its function is to transform from liquid to solid upon UV light exposure after being sprayed onto a substrate, resulting in surface hardening. It offers scratch resistance and a glossy, aesthetically pleasing, and smooth finish, and features excellent adhesion, high gloss, superb smoothness, great leveling, and rapid curing.

The exterior surfaces of plastic products.

Check out the quality inspection process of spray painted parts at 3DSPRO.

Color

Verify if the color matches the system-indicated color (ensure no gray is sprayed as black or black as gray). If the color is correct, compare it with the Pantone color code to check if the difference is significant.

Gloss/Matte Finish

Confirm whether the gloss or matte finish meets the customer’s requirements, and ensure there are no instances of one side being glossy and the other matte without the customer’s specification.

Surface

Check for any wet paint. Inspect for paint loss due to collision.

Color Uniformity

Assess if there is uneven coloration (white showing through black, areas darker or lighter).

Determine if there is paint accumulation or peeling.

Bubbles

Identify any presence of bubbles.

Scratches

Look for any obvious scratches.

Fine Sanding

Evaluate if the fine-sanded polished product meets the requirements.

Check out the frequently asked questions of spray painting.

to get the paint Color Chart.

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept