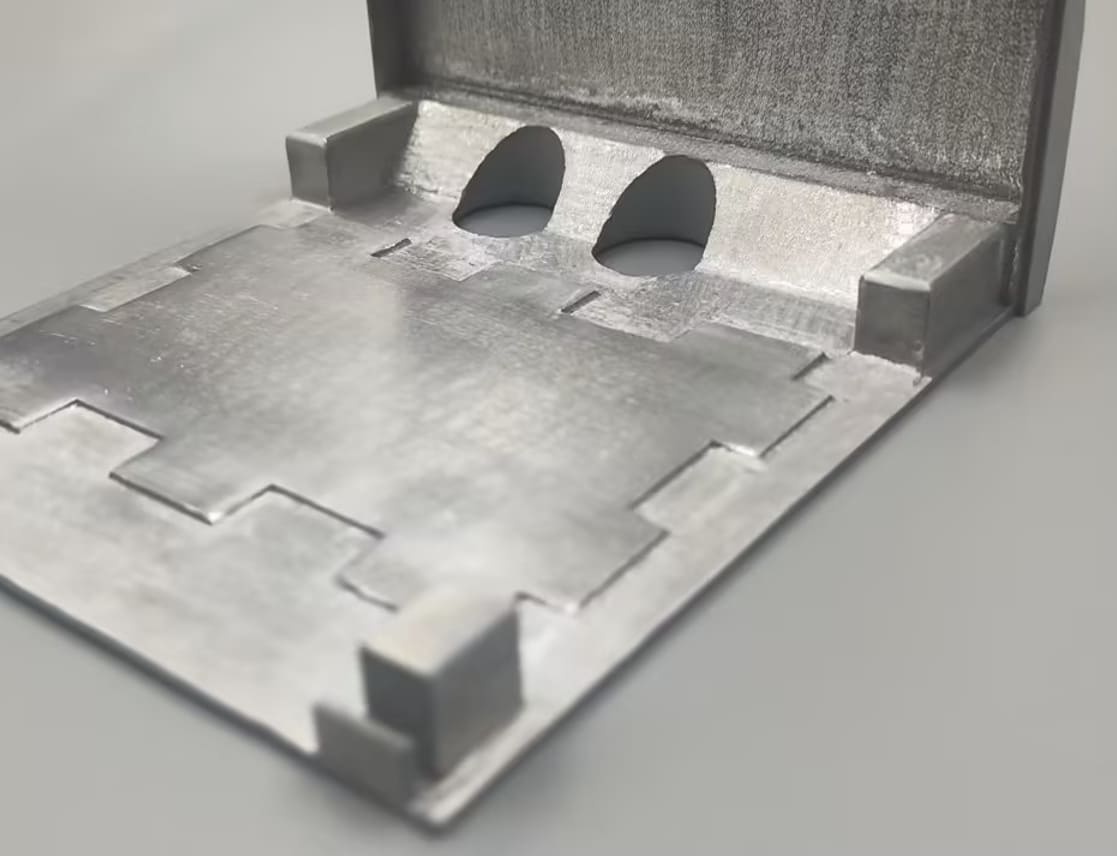

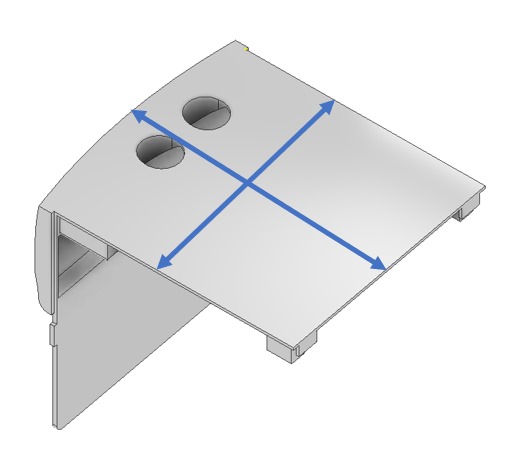

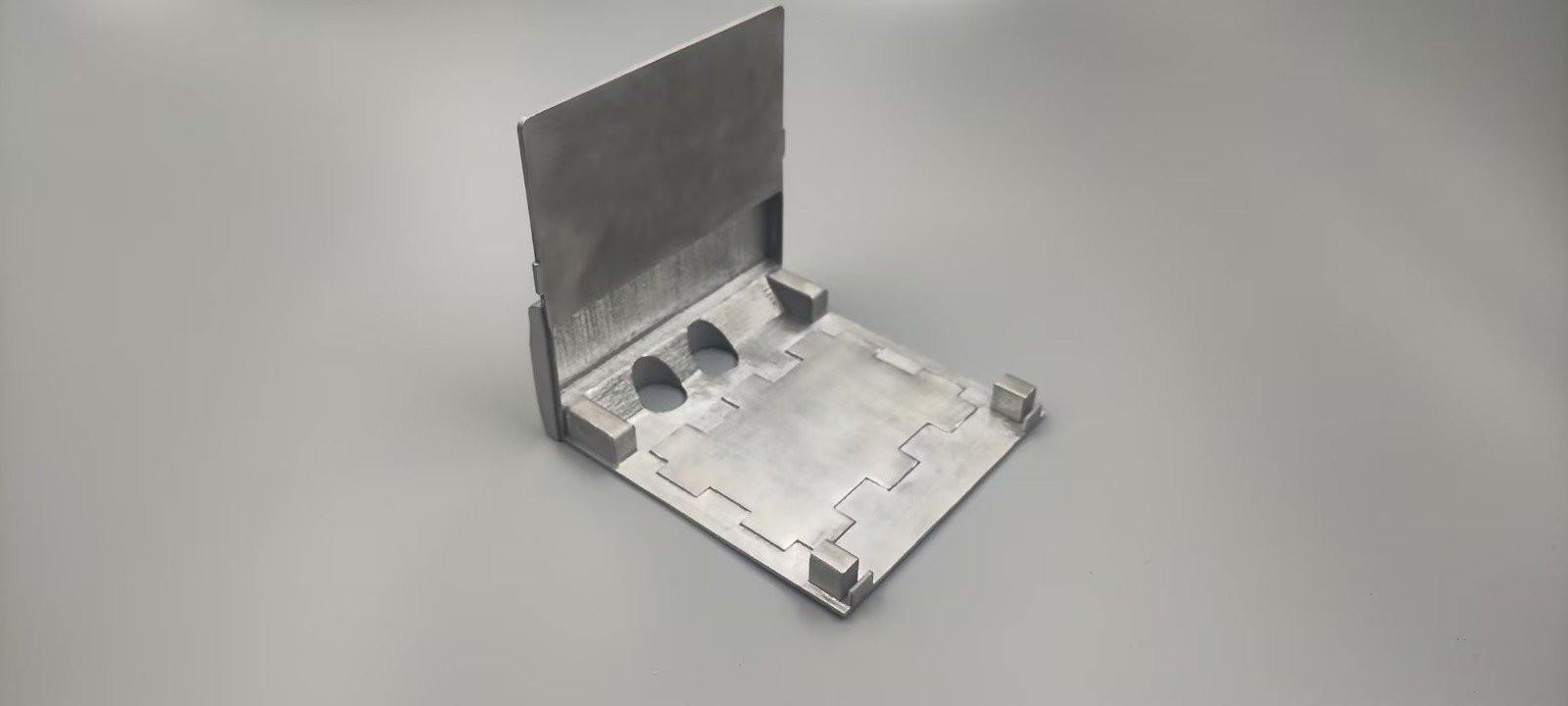

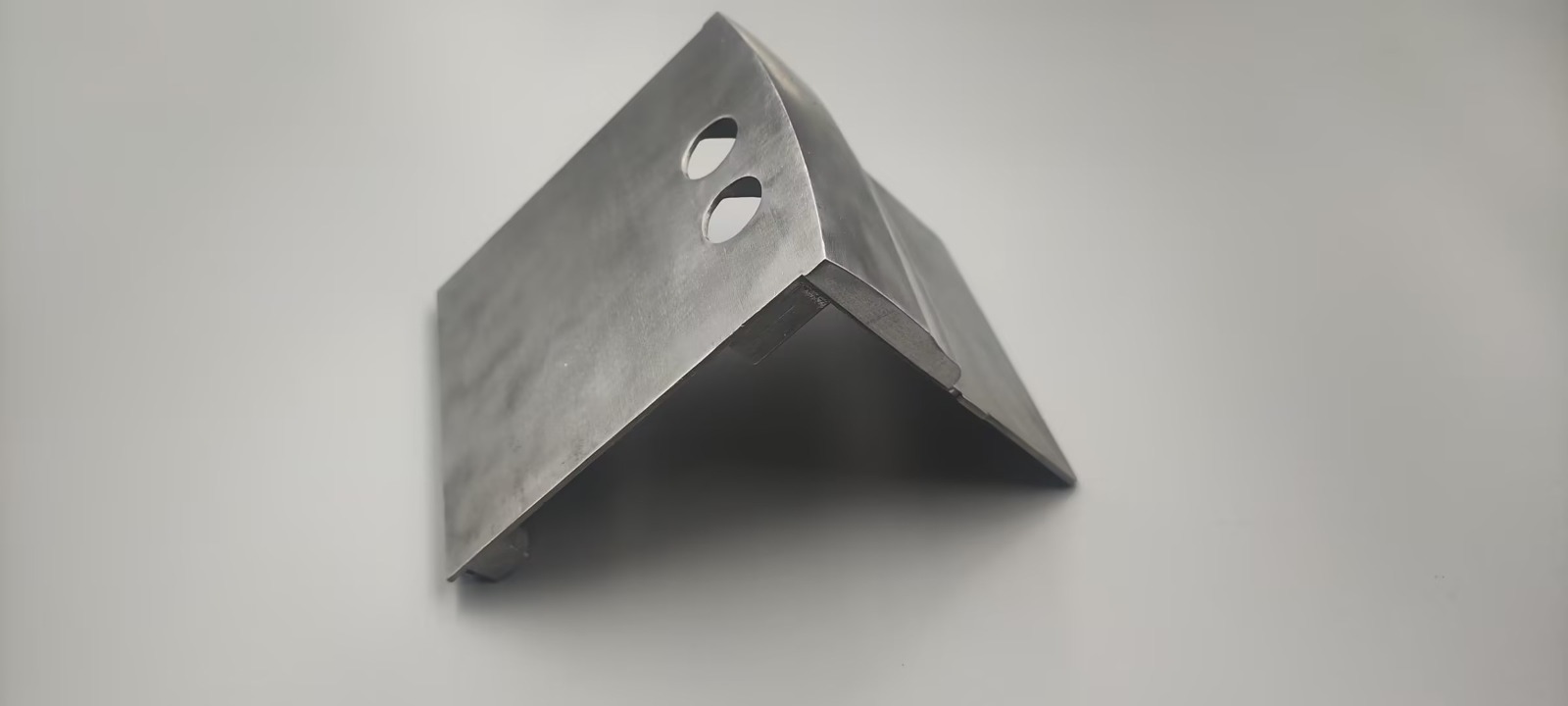

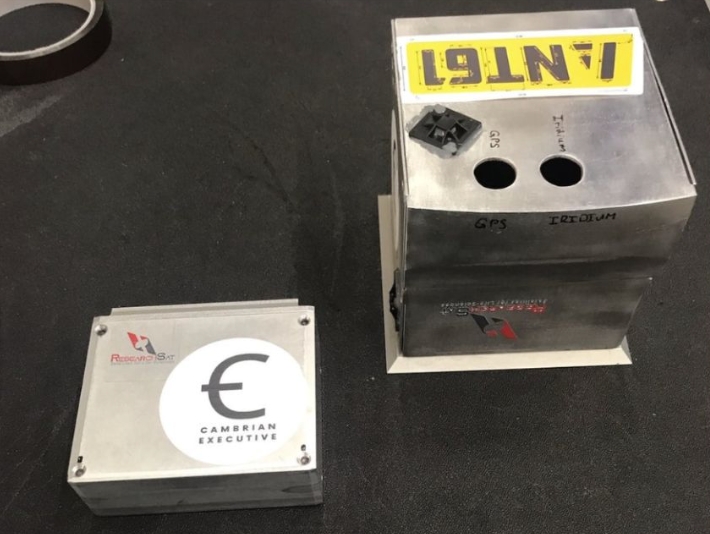

The metal 3D printed part functioned as a tight-fitting cover protecting vital subsystems of ResearchSat's Advanced Diagnostic Laboratory - Electronic payload or, for short, ADI-E payload. It mainly protected ADI-E's flight computer and both the sub-payloads of ResearchSat's clients for the MAPHEUS 14 suborbital rocket flight mission. MAPHEUS 14 was a successful sounding rocket mission that flew on the 27th of February 2024 from Esrange Space Center, Kiruna, Sweden.

Taking into consideration the expected dynamic loads over the course of the rocket flight and the required size, shape, and tolerances for a close fit, the part was specially designed and carefully machined, and optimum levels of post-printing processing were applied to achieve the final flight-ready part.

A 3D Printed Aluminum Part

● Process: Selective Laser Melting (SLM)

● Material: Aluminum AlSi10Mg

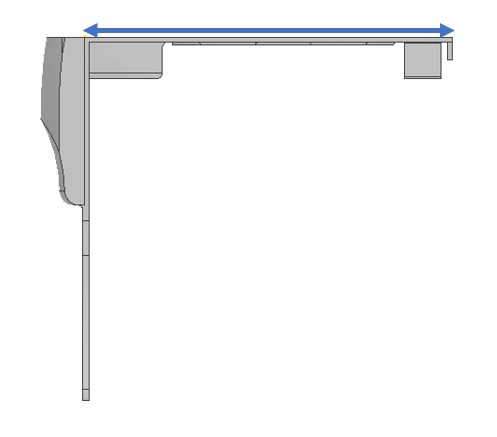

● Part Dimensions: 99.90 x 98.80 x 111.90 mm

We collaborated with ResearchSat to manufacture a precision-engineered, tight-fitting cover for the MAPHEUS 14, using Selective Laser Melting (SLM) technology and Aluminum AlSi10Mg. As an advanced metal 3D printing process, SLM enabled us to create a strong and lightweight cover that successfully protected the vital subsystems during the mission. The precise dimensions and material properties of the metal cover ensured optimal performance under the demanding conditions of space travel, demonstrating the reliability and effectiveness of SLM and Aluminum AlSi10Mg in aerospace applications.

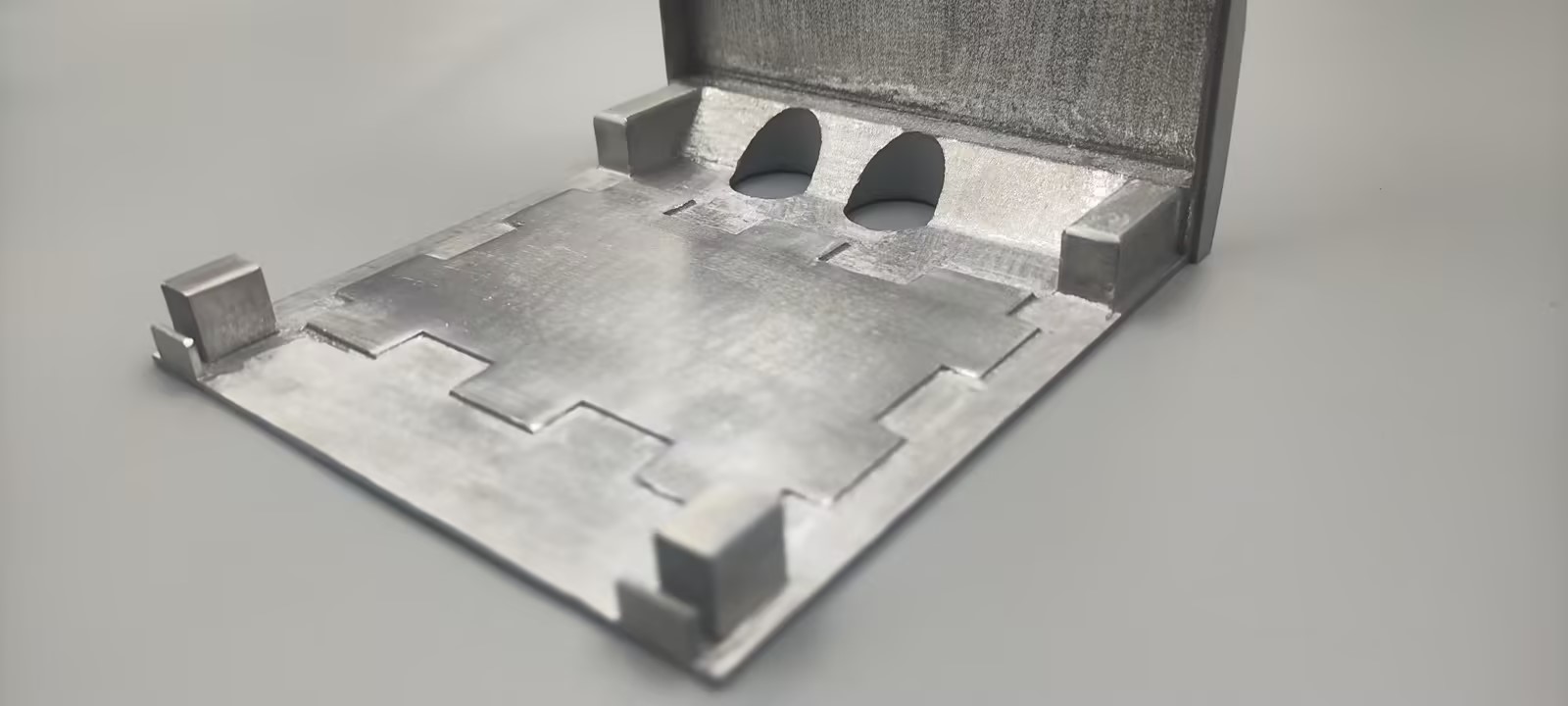

Polishing

● 3D Plus™ Post-processing: Polishing

Polishing was the post-processing method requested by the client to improve the surface finish of the metal cover. The two vertical outer surfaces were polished according to normal standards. The interior was polished as much as possible because tools and manual methods cannot fully process the internal corners, so it would be impossible to guarantee that the interior is fully polished.

For this case, we recommended that our client use brushed polishing instead of mirror polishing or high mirror polishing. Although mirror polishing is feasible and achievable, it is very time-consuming and laborious. In addition, high-level polishing is unnecessary for this type of metal cover for industrial use. Therefore, brushed polishing was the most cost-effective and highly efficient option.

High Dimensional Accuracy

Aerospace parts require high precision, and this metal 3D printed cover is no exception. To ensure the utmost accuracy, we conducted a thorough dimensional check on the metal cover. This check involves measuring the part, comparing it to design specifications, using 3D scanning for detailed analysis, evaluating surface finish, ensuring geometric tolerances, and performing final verification to ensure precision and accuracy, which is a crucial part of our quality inspection standard operating procedures. It guarantees that the part meets the stringent standards required for aerospace applications.

In this case, the dimensional check ensured the cover’s precision and helped our client understand how easily it would fit with the rest of the assembly. By performing a dimensional check, we aimed to address their concerns and ensure a seamless integration with the other components.

Performing dimensional check was essential to verify the reliability of additive manufacturing (AM) for aerospace parts. It also demonstrated our commitment to quality and precision, reinforcing our client’s confidence in the use of metal 3D printing. Ultimately, this process ensured that the metal 3D printed cover would perform optimally under the demanding conditions of aerospace applications.

Customer Supports

Additionally, the client was very pleased with our lead time as we delivered this critical 3D printed metal part quickly, ensuring their project stayed on schedule. The successful metal 3D printed part eliminated the need for CNC machining to produce the part, significantly reducing lead time and cost. Timely, responsive communication was critical throughout the service process, as there were many details to discuss and confirm. Our goal is to have the client use the produced part immediately for testing or application, so fast, professional communication is essential. This is a key reason the client trusts us.

Overall, we were successful in manufacturing a tight-fitting metal 3D printed cover and ensuring ResearchSat’s project performed as expected.

We’ve previously written some insights into 3D printing in aerospace. If you’re interested, you can read more here.

COMMENTS

- Be the first to share your thoughts!