3D Printing Streamlines Aerospace Manufacture Workflow

3D printing, also known as additive manufacturing, has streamlined the aerospace manufacturing workflow by integrating a level of flexibility, efficiency, and innovation.

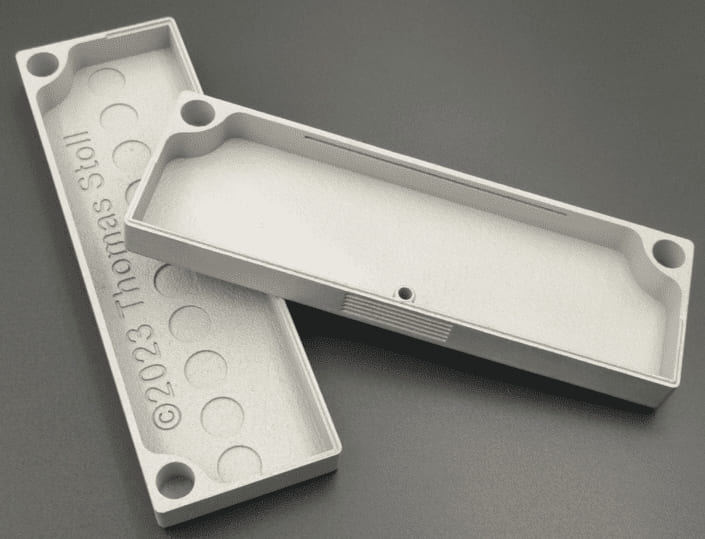

Streamlining Design and Prototyping

The aerospace industry, known for its complex components and stringent quality requirements, has embraced 3D printing to streamline its design and prototyping stages. Engineers can now iterate designs rapidly, testing and refining aerospace components with high precision and less material waste.

Reducing Lead Times and Costs

By integrating 3D printing into the manufacturing workflow, aerospace companies have significantly reduced lead times and costs associated with the production of parts. Traditional manufacturing methods often require multiple steps and tools, each adding time and expense to the process. In contrast, 3D printing can produce complex geometries in a single step without the need for additional tooling, resulting in faster production times and lower costs.

Enhancing Supply Chain Efficiency

The aerospace industry benefits from 3D printing’s ability to produce parts on-demand, which simplifies inventory management and reduces the need for storage space. This on-demand production capability also means that aerospace manufacturers can respond quickly to the need for replacement parts, thus minimizing aircraft downtime.

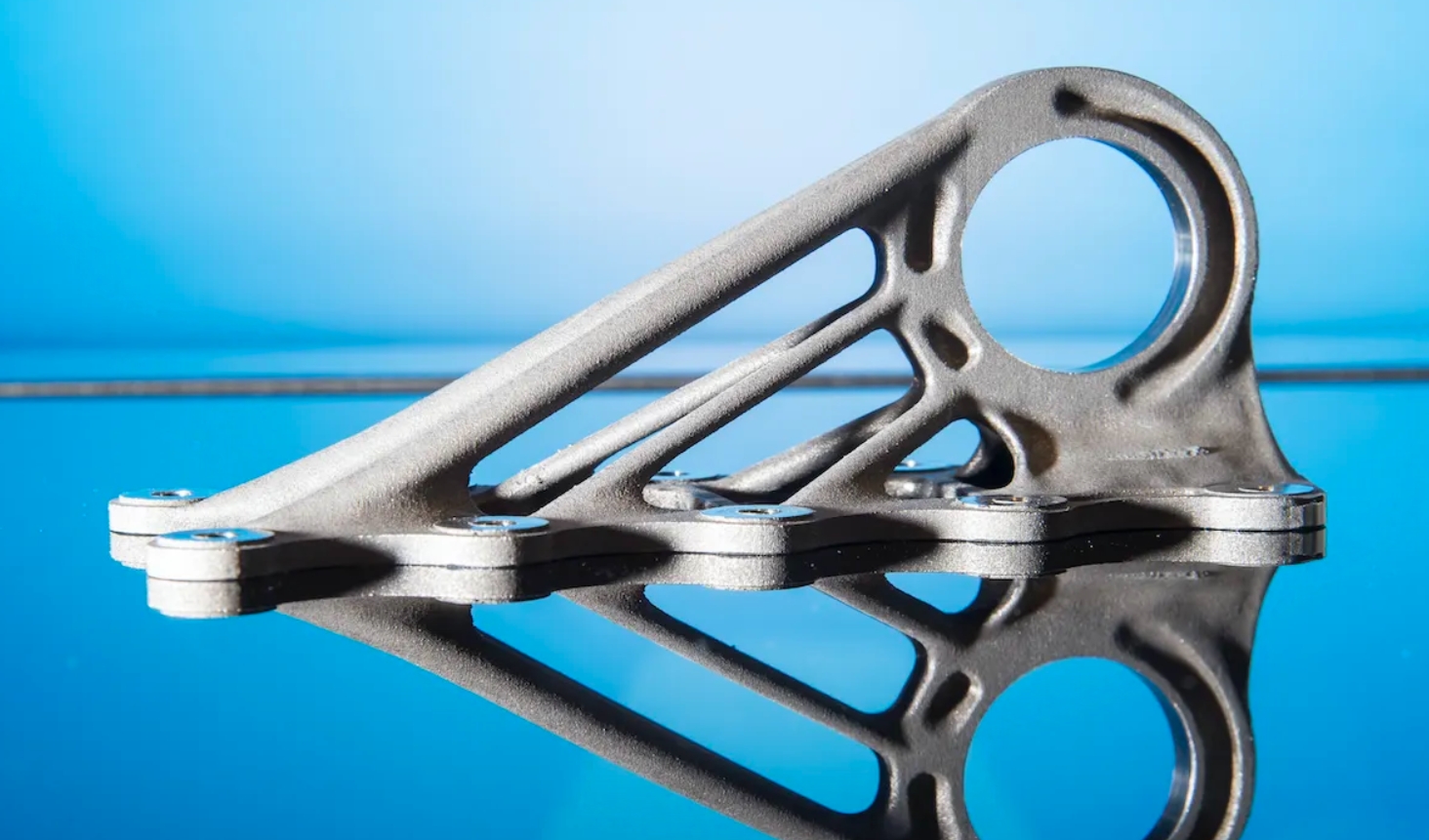

Customization and Complexity

3D printing allows for the creation of parts with complex internal structures that are often impossible to achieve with traditional manufacturing, which enables aerospace engineers to design parts that are lighter yet stronger, contributing to the overall efficiency and performance of aerospace vehicles.

Image Source: Airbus

3D Printing Applications in Aerospace

Prototyping and Testing

3D printing is extensively used for creating detailed prototypes for aerodynamic testing and design validation, which allows for rapid iteration and refinement of parts such as airfoils, fuselage sections, and engine components before final production.

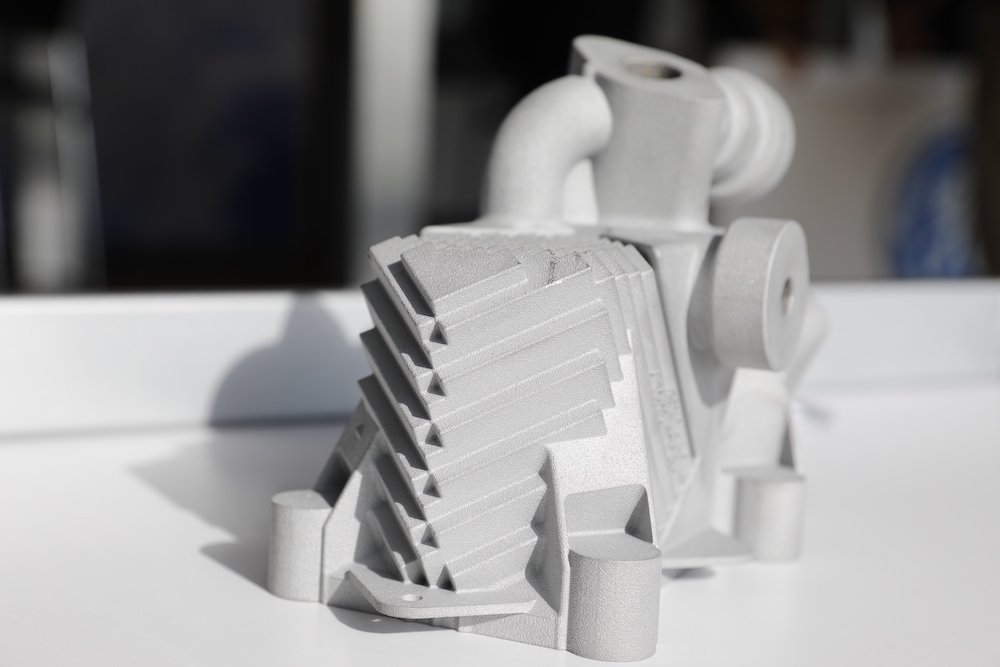

End-Use Parts

Aerospace companies are increasingly using 3D printing to produce end-use parts. These include components like brackets, ductwork, and even more complex parts such as fuel nozzles and turbine blades, which benefit from the weight reduction and complex geometries that 3D printing offers.

Tooling

Additive manufacturing is utilized to create custom tooling for the production of aerospace components, including jigs, fixtures, and molds, which can be produced quickly and at a lower cost compared to traditional tooling methods.

On-Demand Manufacturing

The ability to print parts as needed reduces the necessity for large inventories and enables the production of parts on-demand, especially for legacy aircraft where replacement parts may no longer be in production.

Customization for Small Batches

For military or specialized aerospace applications, 3D printing allows for the customization of parts in small batches, catering to specific mission requirements without the need for large-scale production runs.

Repair and Maintenance

3D printing offers new methods for repairing and maintaining aircraft parts. Instead of replacing an entire component, damaged areas can be rebuilt using additive manufacturing, extending the life of the part.

Complex Geometries and Lightweight Structures

The design freedom of 3D printing enables the creation of parts with complex internal structures that are not possible with traditional manufacturing, which leads to lighter components that maintain strength and durability, crucial for aerospace applications.

Integration of Electronics

Advancements in 3D printing technologies allow for the integration of electronics into printed parts, paving the way for innovative solutions like sensor-embedded components and smart structures.

Image Source: TCT Magazine

Suitable 3D Printing Materials and Process for Aerospace Industry

3D Printing Materials for Aerospace Parts

Thermoplastics and Polymers

These are the most commonly used materials in aerospace 3D printing. They offer a good balance between weight, strength, and flexibility. Examples include PEEK and ULTEM, which provide excellent thermal and chemical resistance.

● PEEK (Polyether Ether Ketone): A high-performance thermoplastic with excellent mechanical and chemical resistance properties. It’s known for its durability and ability to withstand high temperatures, making it suitable for critical aerospace components.

● ULTEM (Polyetherimide): Another high-performance polymer that offers outstanding thermal stability and strength. It’s flame-retardant and can operate in high-temperature environments, which is crucial for aerospace applications.

Metal Alloys

Metals like titanium, aluminum, and nickel alloys are favored for their high strength-to-weight ratio and durability. They are often used for critical components such as engine parts and structural elements.

● Titanium Alloys: These are favored for their high strength-to-weight ratio and corrosion resistance. Titanium alloys are often used in the manufacturing of airframe structures and engine components due to their ability to withstand extreme conditions.

● Aluminum Alloys: Lightweight and strong aluminum alloys are used for a variety of aerospace parts, including brackets and housings. They are easier to print compared to other metals and offer good thermal and electrical conductivity.

● Nickel Alloys: Known for their high-temperature resistance and strength, nickel alloys are ideal for parts like turbine blades and exhaust systems. They maintain their properties even under thermal stress, making them essential for engine-related components.

Composite Materials

Composites, which may include carbon fiber or glass fiber reinforcements, are used for their lightweight and high-strength properties. They are particularly useful for parts that require additional stiffness without adding significant weight.

● Carbon Fiber Reinforced Polymers: These composites offer high stiffness and strength while remaining lightweight. They are used in applications where weight savings are critical, such as in the manufacturing of fuselage panels and wing structures.

● Glass Fiber Reinforced Polymers: While not as strong as carbon fiber, glass fiber composites still provide significant weight advantages and are used in less critical components where cost savings are a priority.

3D Printing Processes for Aerospace

Fused Deposition Modeling (FDM)

FDM is widely used for prototyping and tooling due to its cost-effectiveness and the ability to print large parts. It works by extruding thermoplastic filaments through a heated nozzle, layer by layer.

Selective Laser Sintering (SLS) and Selective Laser Melting (SLM)

These powder bed fusion processes are used for creating complex metal and polymer parts. A laser selectively sinters powdered material to form solid structures.

Electron Beam Melting (EBM)

EBM is similar to DMLS but uses an electron beam instead of a laser. It’s particularly suited for printing high-density metal parts with excellent mechanical properties.

Material Jetting

Material Jetting offers high precision and is capable of printing parts with multiple materials or colors. It works by jetting droplets of material that are cured with UV light.

Image Source: TCT Magazine

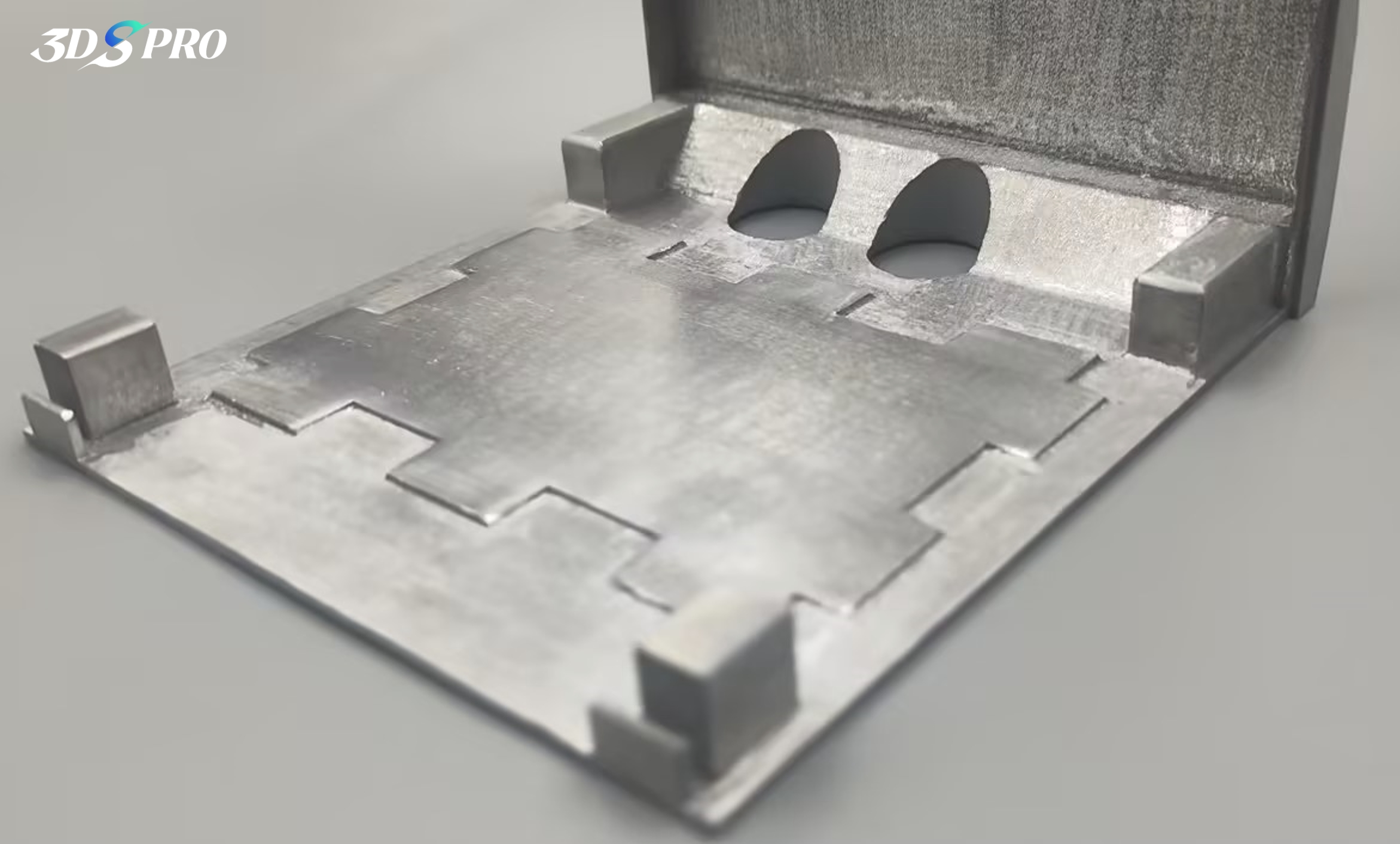

3DSPRO 3D Printing Solutions for Aerospace

3DSPRO provides advanced 3D printing solutions tailored for the aerospace industry. With a focus on Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Selective Laser Melting (SLM) technologies for the aerospace industry, we are experienced in the production of aerospace components, including specialized rocket parts.

The aerospace industry demands the highest standards of quality and precision, and 3DSPRO meets these requirements by delivering components that are structurally sound and optimized for performance. With 3DSPRO’s 3D printing solutions, aerospace clients can expect reduced lead times, lower costs, and enhanced product performance. See the Cost of 3D Printing Aerospace Parts >>

COMMENTS

- Be the first to share your thoughts!