Imagine a rose that never withers and always remains beautiful. It may sound like a fairy tale, but thanks to 3D printing, it is now a reality. 3D printing can create a rose that can be customized to any color, shape, or size, with even the most delicate petals carefully crafted. 3D printed rose embodies timeless elegance and unfading charm. Let's explore the 3D printed metal rose we made in this article!

3D Printed Rose

In the world of floristry, roses have always symbolized beauty, love, and elegance. However, their ephemeral nature means they eventually wilt and fade.

3D printed rose brings us a timeless beauty that never fades. The Floristry, a professional and creative floral design company, recently collaborated with us to create a stunning 3D printed rose using metal 3D printing techniques. The post-processing method of bead blasting gives the 3D printed rose a natural sheen and a shiny finish. This innovative approach preserves the aesthetic appeal of a natural rose and aligns with eco-friendly principles.

The Metal 3D Printing Process

The creation of the 3D printed rose involves a metal 3D printing process known as Selective Laser Melting (SLM). SLM 3D printing uses a high-energy laser to melt fine metal powder layer by layer, constructing the rose from the ground up. SLM is ideal for achieving intricate details and complex geometries, making it perfect for replicating the delicate petals of a rose.

The Detailed Leaf Margin, Torus, Sepal, Peduncle, and Thorn of the 3D Printed Rose

Our SLM 3D Printing Capabilities

|

Process |

Price |

Lead Time |

Maximum Printing Size |

Tolerance |

Post-processing Types |

|

Selective Laser Melting |

$$$ |

5 Days or 7 Days |

420mm * 420mm * 450mm |

± 300μm or 0.3%mm |

15+ |

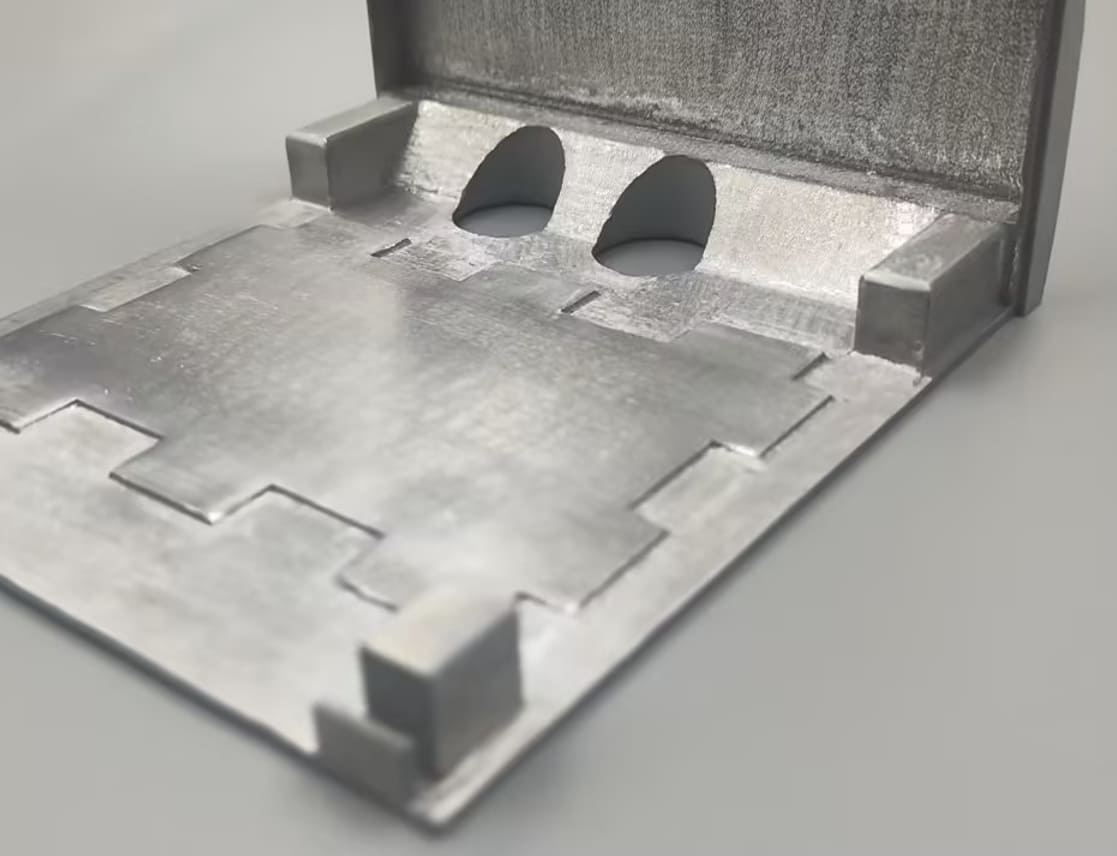

To optimize the printing process, we carefully adjusted the orientation of the rose 3D model on the metal 3D printer. By placing the flower branch at the top and the petals at the bottom, we minimized the need for support structures, which reduces burrs on the as-printed rose and makes post-processing easier and more efficient.

The material chosen for this project is AlSi10Mg, an aluminum alloy known for its excellent mechanical properties and high strength-to-weight ratio. AlSi10Mg material ensures that the 3D printed rose is both durable and lightweight, maintaining its beauty and structural integrity.

Our AlSi10Mg Mechanical Properties

|

Tensile Strength |

Elongation at Break |

Yield Strength |

Hardness |

Roughness Ra |

|

300MPa |

2% |

190MPa |

100 HV |

16 µm |

Post-processing to the 3D Printed Rose

Once the 3D printing process is complete, the rose undergoes post-processing to enhance its appearance and durability.

For this project, bead blasting was used as the post-processing technique. Bead blasting involves propelling small spherical beads at the surface of the rose at high pressure, which smooths out any rough edges and gives the rose a uniform, satin finish. Bead blasting improves the aesthetic quality of the rose and increases its resistance to wear and corrosion. The result is a beautiful 3D printed rose that retains its intricate details and has a smooth and shiny finish.

How do we work with artists with our 3D printing services?

At 3DSPRO, we believe in the power of collaboration between 3D printing and art. Our 3D printing services are designed to empower artists by providing them with the tools and expertise needed to bring their creative visions to life. We work closely with artists to understand their unique requirements and offer customized solutions that cater to their specific needs.

In this case, we noticed that the 3D printed rose lacked gloss, and the surface finish was uneven after the initial bead blasting. Recognizing that this would not meet the artistic standards required, we decided to send the rose for rework. After additional processing, we achieved a pleasing and satisfactory outcome, with a smooth and glossy finish that met our expectations.

After Bead Blasting Rework

From initial concept to final product, our team of experts guides artists through every step of the process, ensuring their artistic integrity is maintained while leveraging the precision and versatility of 3D printing. We are confident that this collaborative approach will lead to countless innovative and inspiring works of art.

Art and Design x 3D Printing

The intersection of art and 3D printing is an emerging field that is redefining traditional boundaries and opening up new possibilities for creative expression. Artists are no longer constrained by traditional materials and techniques. With 3D printing, they can explore new forms, textures, and structures that were previously unattainable. 3D printing enables artists to create unique works based on their personal preferences. In addition, 3D printing is a sustainable alternative that reduces waste and minimizes the environmental impact of art production.

In our case, the timeless 3D printed rose created by The Floristry and 3DSPRO embodies the perfect fusion of art and technology. It demonstrates how 3D printing can preserve the timeless beauty of nature while providing new avenues for artistic exploration.