We Helped Bennett Awards Make A ‘Drinkable’ Golden Boot

● Client: Bennett Awards

● Product: La Bota Especial

● Process: SLM 3D Printing

● Material: Aluminum 6061

At 3DSPRO, we pride ourselves on delivering exceptional work for our clients, always striving to bring unique and meaningful creations into the world. Recently, Bennett Awards approached us with an unusual request: to create a “drinkable” golden boot that could be filled with Modelo beer and used as a drinking vessel.

Ryan, the design director at Bennett Awards, shared, “Our customer came to us with a weird request to have a ‘drinkable’ golden boot. Bennett Awards, being who we are, never turns down a strange request. I honestly think that Bennett can build or make anything with enough time, technology, and money, so I was happy to take on a job that our client confessed a dozen other companies had turned down.”

At 3DSPRO, we share this commitment to tackling unique and complex projects. We believe in our ability to manufacture products with intricate and unconventional shapes, thanks to our diverse 3D printing capabilities. Partnering with Bennett Awards, we were confident in our ability to accomplish this seemingly impossible mission.

To bring the golden boot to life, we utilized Selective Laser Melting (SLM) 3D printing technology with Aluminum 6061. SLM 3D printing allowed us to achieve the complex geometries required and meet the tight development timeline. The result was a stunning, functional piece that exceeded our client’s expectations.

Mechanical Properties of Aluminum 6061

|

Tensile Strength |

Elongation at Break |

Hardness |

Yield Strength |

Color |

|

290 MPa |

10% |

95HB |

240 MPa |

Metallic |

How did we work together?

3DSPRO and Bennett Awards are thrilled to embrace challenges and are determined to achieve remarkable outcomes in this project. “When we succeed in building objects with difficult parameters that other agencies turn down, it’s both incredibly motivating and extremely satisfying. I honestly believe there’s nothing we can’t build, and that is an incredibly powerful feeling for a designer,” said Ryan.

Upon receiving Ryan’s message about creating a golden boot, we were filled with excitement and immediately began preparations for this unique request. We confirmed the material, the preferred process, the parameters, the quantities, and the lead time. Once everything was set, we got started! All pieces were delivered to Bennett Awards safe and sound, right on time. “Partnering with companies like yours gives us the confidence to tackle some of these crazy projects, so thank you,” Ryan added.

If you’re interested in how our Metal 3D Printing Service works, here are the Standard Operating Procedures (SOP):

● Step 1: Printability check.

● Step 2: Import files on the metal 3D printers.

● Step 3: Optimize build chamber space.

● Step 4: Metal 3D printers operating: powder bed preparation, laser scanning and melting, solidification and bonding.

● Step 5: Cool down.

● Step 6: Take the metal 3D printed part out of the build chamber.

● Step 7: Clean residue metal powders.

● Step 8: Send metal 3D printed parts to heat treatment.

● Step 9: Post-processing (optional).

● Step 10: Quality inspection.

● Step 11: Packing and shipping.

3D Printed Shoe? A Metal 3D Printed Boot!

3D printed shoes have become quite common in the 3D printing industry, and we’ve even written an article titled “The Rise of 3D Printed Shoes” to explore this trend. However, a metal 3D printed boot, similar to the cleats worn by soccer players? That’s something we haven’t seen in the market yet.

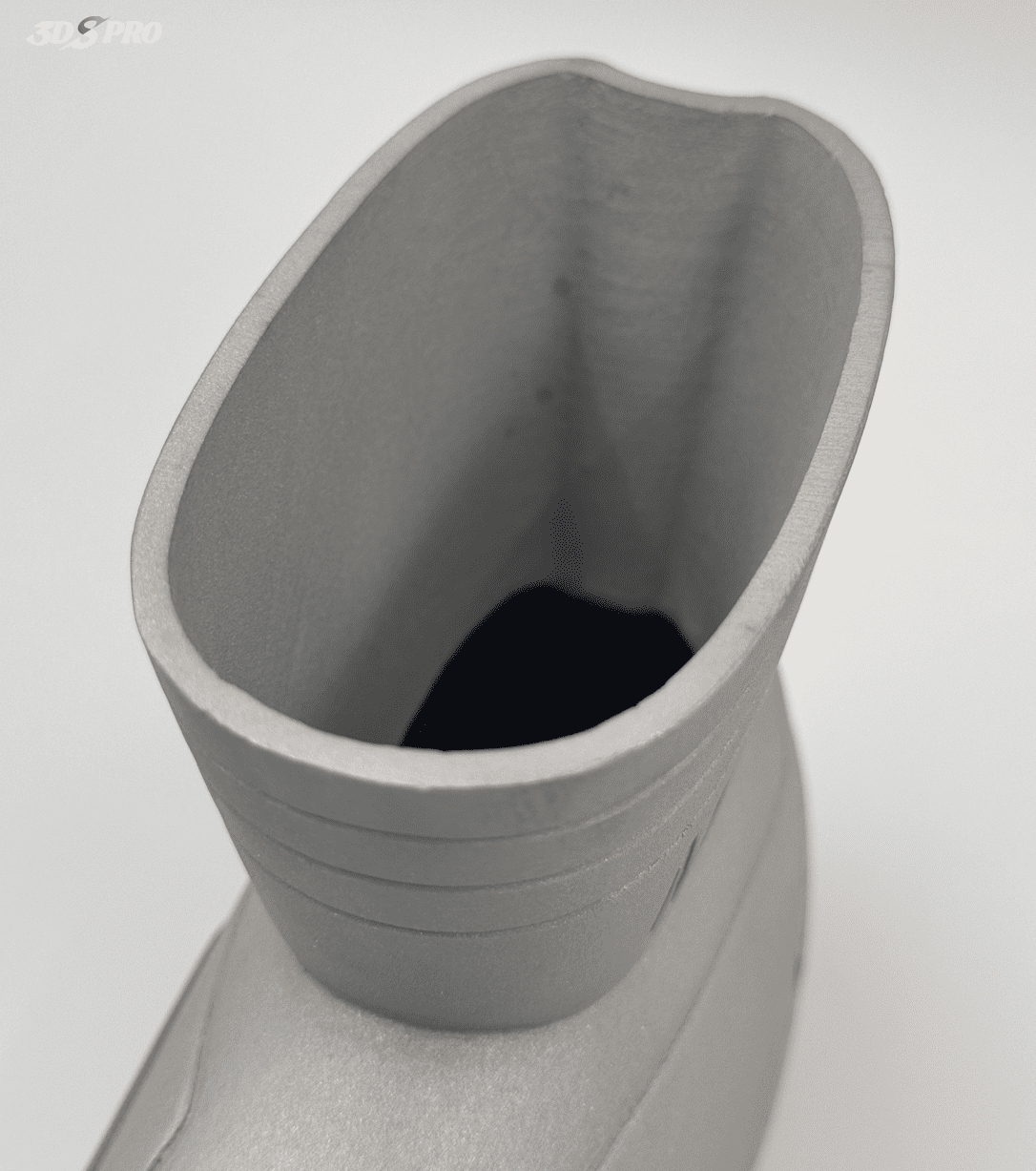

Our latest project involved creating a metal 3D printed boot, and it’s not just any boot—it’s the actual shoe size of Mexican defenseman Edson “El Machín” Álvarez! This challenging project showcases the potential of metal 3D printing in producing highly customized and durable footwear.

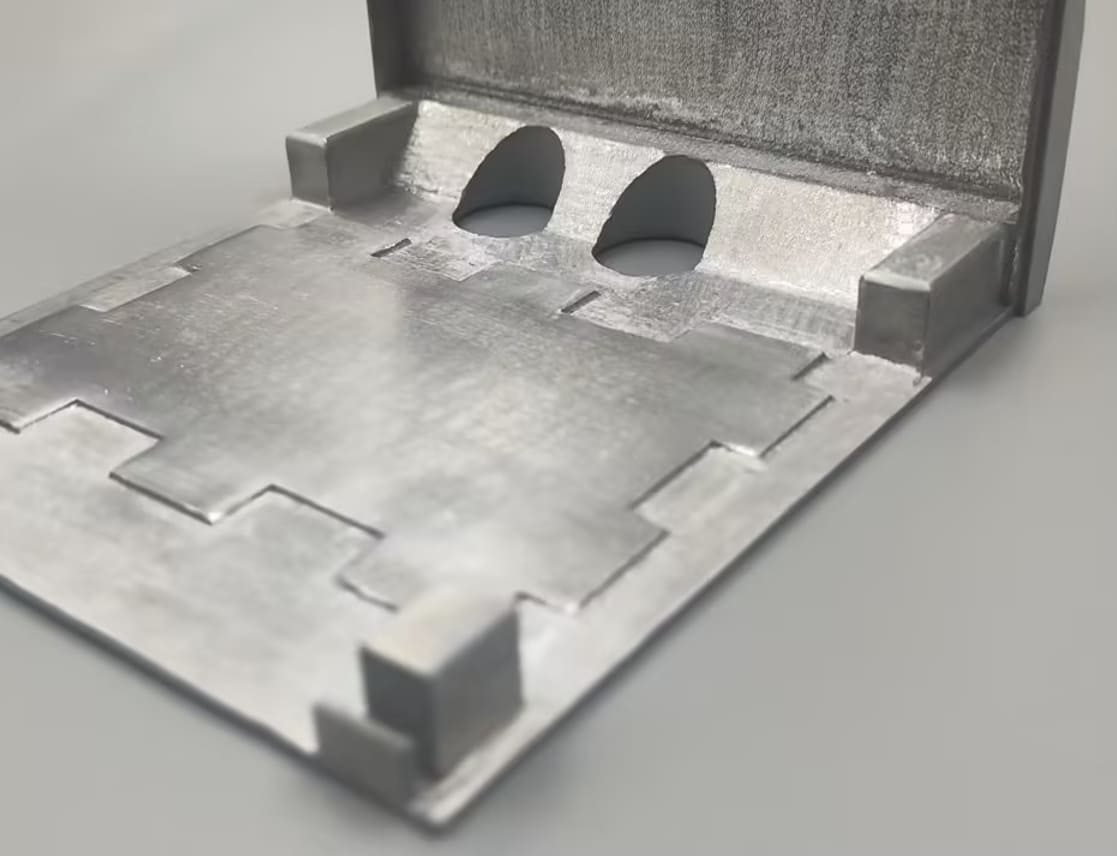

A metal 3D printed boot:

The print-in-place metal boot with a hollow structure:

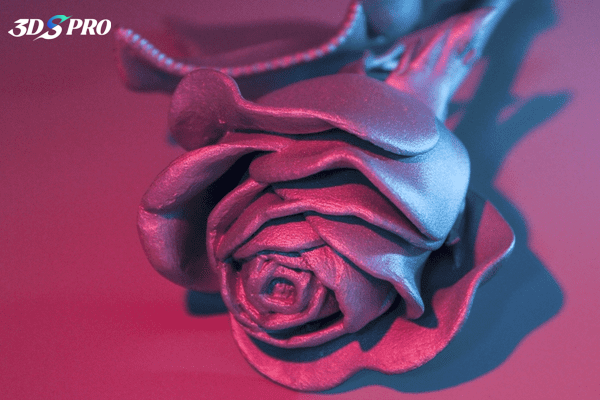

The engraved and embossed details:

The outsole with spikes and embossed logos:

Why choose 3D printing?

“In this case, the unusual request and its tight turnaround time led us to one solution: 3D printed metal. While we could have employed various other methods, given our experience with metal casting foundries as a sculpture studio, the idea of creating this object using a material and process that, to my knowledge, has never been attempted before was thrilling. Have you ever heard of a life-size, 24k gold-plated, 3D printed metal football boot that you can drink beer out of? Probably not!” said Ryan.

Besides, there are several compelling reasons to use 3D printing for making shoes:

1. Customization: 3D printing allows for complete customization, enabling the creation of shoes tailored precisely to an individual’s foot shape and size, which ensures a perfect fit and maximum comfort.

2. Complex Designs: It enables the production of intricate and complex designs that would be difficult or impossible to achieve with traditional manufacturing methods, opening up new possibilities for innovative and unique footwear.

3. Sustainability: 3D printing can be more sustainable as it often uses less material and produces less waste compared to traditional manufacturing.

4. Rapid Prototyping: It allows for quick prototyping and iteration, which is particularly useful in the design phase. Designers can quickly test and refine their ideas before moving to full-scale production.

5. Innovation in Materials: 3D printing technology is continually evolving, with new materials being developed that offer enhanced properties such as flexibility, durability, and shock absorption.

Electroplated with 24K Gold

“Ultimately, we wanted these gold-plated as a nod to the gold foil on the neck covering the cap on every bottle of Modelo. So, we electroplated them in 24k gold. We had to do some minimal manual metal cleanup of some visible layer lines prior to plating, using rotary tools and media blast material. Following gold plating, we coated the inside of the boot cavity with a food-safe organic sealant,” said Ryan.

Electroplating is a process that uses an electric current to deposit a thin layer of metal onto the surface of another material. This technique is used to improve the appearance, durability, and corrosion resistance of objects.

“The process for electroplating the boots is basically the same as electroplating any other type of 6061 aluminum. There are a few tweaks to the preprocess to get the parts cleaned properly prior to plating, but it’s essentially the same. You just need to pay attention to any ‘bad metal’ spots where you might get some pitting. If you grind, blast, and finish those out properly, you’ll be fine,” said Ryan.

Since metal 3D printed parts have a relatively grainy and rough surface, the key point in this case is to make the surface of the boot smooth before 24k gold electroplating. Bennett Awards chose bead blasting and rotary tools for this purpose.

To Be Continued

There are many challenges waiting for us to overcome and ‘impossible missions’ to accomplish. “The biggest problem we faced in this case was managing the timeline. Many of our customers are unaware of how long these processes take, which sometimes puts us in a tight spot with unrealistic deadlines. This was a major factor in deciding our approach. Fortunately, you confirmed the production timeline, and here we are,” said Ryan.

We have collaborated with many designers and engineers. Ryan is one of our loyal long-term customers. He has participated in our user research and has placed numerous orders with us, establishing a strong trust-based relationship. Therefore, he trusts us deeply. We aim to earn the trust of more ‘Ryan’ by providing the best possible 3D printing services.

We strive to help every client achieve success, regardless of the challenges or ‘impossible’ difficulties. We are here to turn each of your projects into a success story!

COMMENTS

- Be the first to share your thoughts!