Selective Laser Melting is the Process

Selective Laser Melting

In our case study, we worked with Bennett Awards to create 3D printed boots using Selective Laser Melting.

Selective Laser Melting, also known as SLM 3D printing, uses a high-powered laser to selectively melt metal powders such as aluminum, titanium, stainless steel or maraging steel layer by layer. SLM 3D printing is able to produce fully dense metal parts with excellent mechanical properties and complex geometries. It is used across a wide range of industries to create durable, lightweight, high-strength parts.

Metal 3D Printing Capabilities (Based on this case study.)

|

Items |

Process |

Material |

Price |

Quantities |

Lead Time |

Tolerance |

|

Life-size Boots |

$$ |

20 Pieces |

5 Days |

±0.3%mm |

Mechanical Properties of 3D Printed Aluminum 6061

|

Hardness |

Density |

Tensile Strength |

Elongation at Break |

Yield Strength |

|

95 HB |

2.8 g/cm³ |

290MPa |

10% |

240MPa |

The Metal 3D Printing Process to Make Those Boots

Step 1: Printability check.

Step 2: Import the STL file on the metal 3D printers.

Step 3: Arrange and optimize build chamber space.

Step 4: Metal 3D printers operating: aluminum 6061 powder bed preparation, laser scanning and melting, solidification and bonding, solid part is built.

Step 5: Cool down the metal 3D printed boots.

Step 6: Take the boots out of the build chamber.

Step 7: Clean residue aluminum powders.

Step 8: Send the boots to heat treatment.

Step 9: Quality inspection.

Part 10: Parts that fail quality inspection are sent for rework.

Step 11: Quality inspection again.

Step 12: Packing and shipping.

Selective Laser Melting Materials at 3DSPRO

|

Aluminum |

Stainless Steel |

Titanium |

Maraging Steel |

|

AlSi10Mg |

316L |

Ti₆Al₄V |

18Ni300 |

|

6061 |

17-4 PH |

/ |

/ |

Take A Closer Look

Customer Feedback

“The biggest problem we faced in this case was managing the timeline. Many of our customers are unaware of how long these processes take, which sometimes puts us in a tight spot with unrealistic deadlines. This was a major factor in deciding our approach. Fortunately, you confirmed the production timeline, and here we are.”

“I honestly don’t think there is anything we can't build and that is a crazy powerful feeling for a designer. Partnering with companies like yours that give us the confidence to think that I can pull off some of this crazy stuff, so thank you.”

Life-size 3D Printed Boots

This life-size 3D printed boot was created to the measurements of Mexican defender Edson Alvarez’s shoes. The project demonstrates the capability of metal 3D printing and the potential to create highly customized and durable footwear that can be tailored to the exact measurements and requirements of the wearer.

The boot’s design and sturdy construction showcase the precision and strength that can be achieved with metal 3D printing, highlighting the versatility of metal 3D printing for producing highly durable and customized items.

The Structure

The Shape

SLM 3D printing can produce parts with intricate geometries. This boot features a streamlined design similar to cleats, though it is less complex than honeycomb or lattice structures. SLM 3D printing can easily create this boot with a quick turnaround time.

The Upper

The upper of the metal 3D printed boot is flat with rounded edges. This is a significant advantage of SLM 3D printing over CNC machining because SLM can directly create smooth and rounded corners without additional processing.

Counter

By following the design guidelines, metal 3D printing can successfully produce relief and engraved details. For example, the word "Modelo" is engraved on both the left and right sides of the counter. In addition, there are three engraved horizontal lines surrounding the counter. (If you are unsure of the design guidelines, we can assess printability for you.)

Internal

Another major advantage of SLM 3D printing is its ability to print objects in one piece, even with hollow structures (if the escape hole is sufficiently large). This capability is demonstrated in the internal structure of the metal printed boot. Interestingly, our client plans to pour ‘Modelo Beer’ into the boot! (Honestly, the only time I’ve seen someone drink from a boot was when Daniel Ricciardo did a ‘Shoey’ after winning a Formula 1 race.)

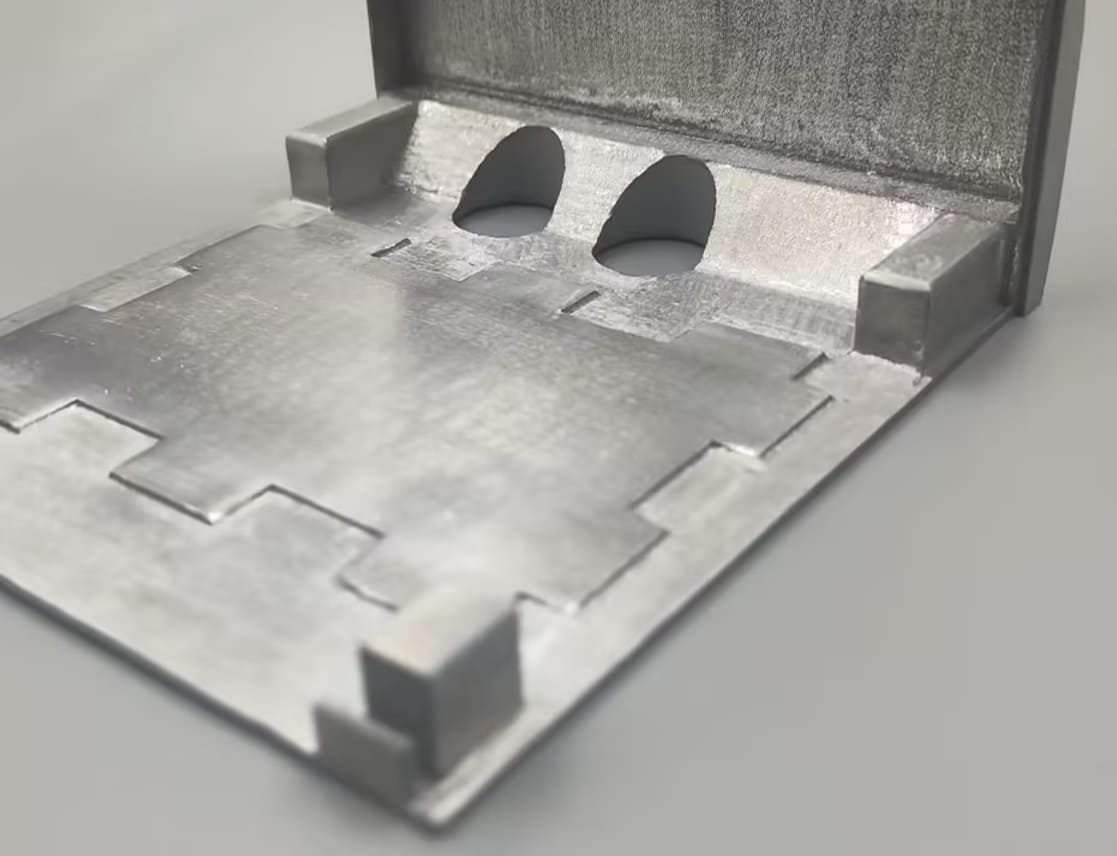

Outsole

The outsole of the boot features embossed details, including the spikes and fonts, all of which have been printed successfully and clearly. The shapes of the spikes are also printed with high accuracy, as can be seen in the following photo.

The Surface Finish

SLM 3D printed parts have a smooth, slightly shiny, but grainy surface finish. The original color is metallic gray, and the surface feels a bit powdery due to the nature of the powder bed fusion process. However, we remove any residual powder as thoroughly as possible.

More Details