The rise of 3D printing in healthcare has revolutionized the production of patient-specific medical implants. However, post-processing—the steps required to refine and sterilize implants after printing—remains a critical challenge. Residual powder, rough surfaces, and contamination risks can compromise implant safety and performance. Today, we’d like to introduce, Himed, a leader in advanced surface technologies, has introduced its MATRIX MCD® Apatitic Abrasive Solution to address these hurdles.

Himed's Study on Post-Processing Challenges in 3D Printed Implants

3D printed titanium and polymer implants often emerge from printers with surface imperfections, including:

- Microscopic roughness: Can irritate tissues or hinder osseointegration (bone growth into the implant).

- Trapped powder particles: Residual metal or polymer powders may cause inflammation or infection.

- Inconsistent textures: Manual finishing struggles with intricate lattice structures common in 3D printed designs.

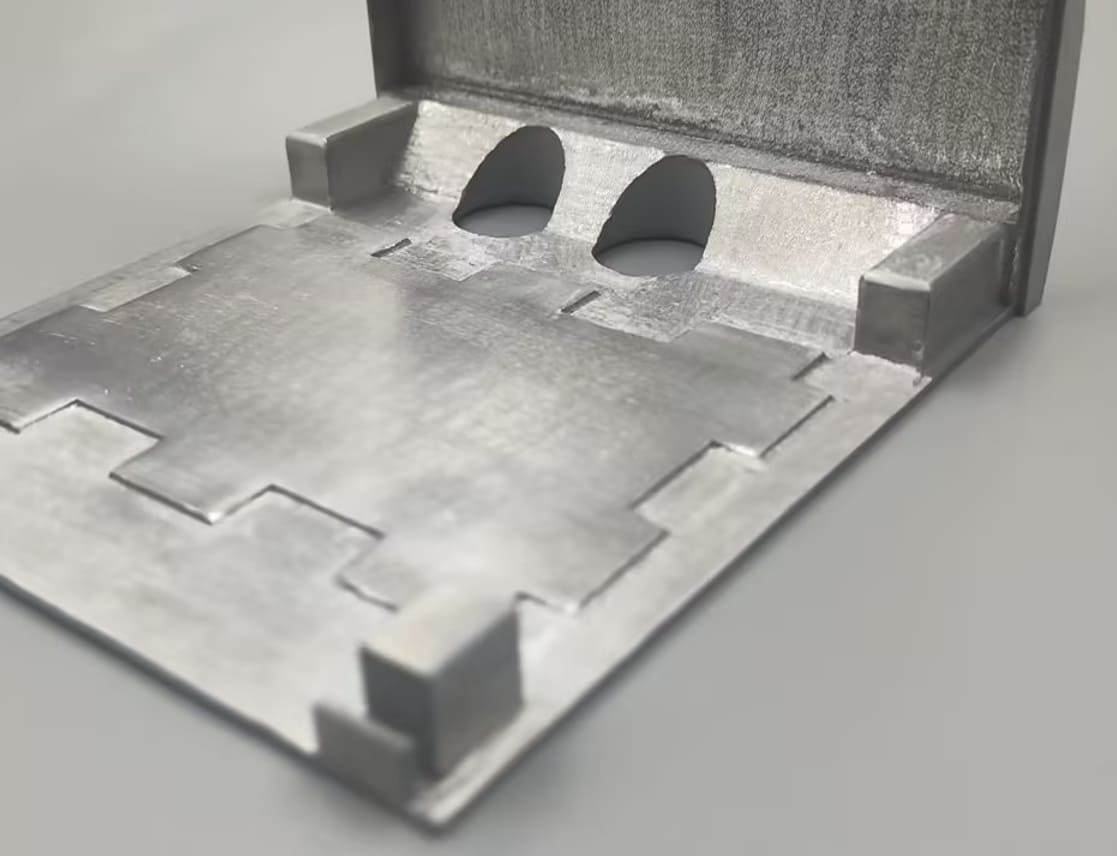

Additive manufacturing introduces surface irregularities, such as residual titanium beads and layer lines, which can detach post-implantation, potentially causing complications. Himed’s research revealed that traditional post-processing methods, such as grit blasting or chemical etching, often fail to uniformly smooth complex surfaces. Worse, abrasive techniques can leave contaminants or alter the implant’s structural integrity. These shortcomings delay healing, increase rejection risks, and limit the clinical potential of 3D printing.

Image Source: Himed

Himed’s MATRIX MCD® Apatitic Abrasive Solution

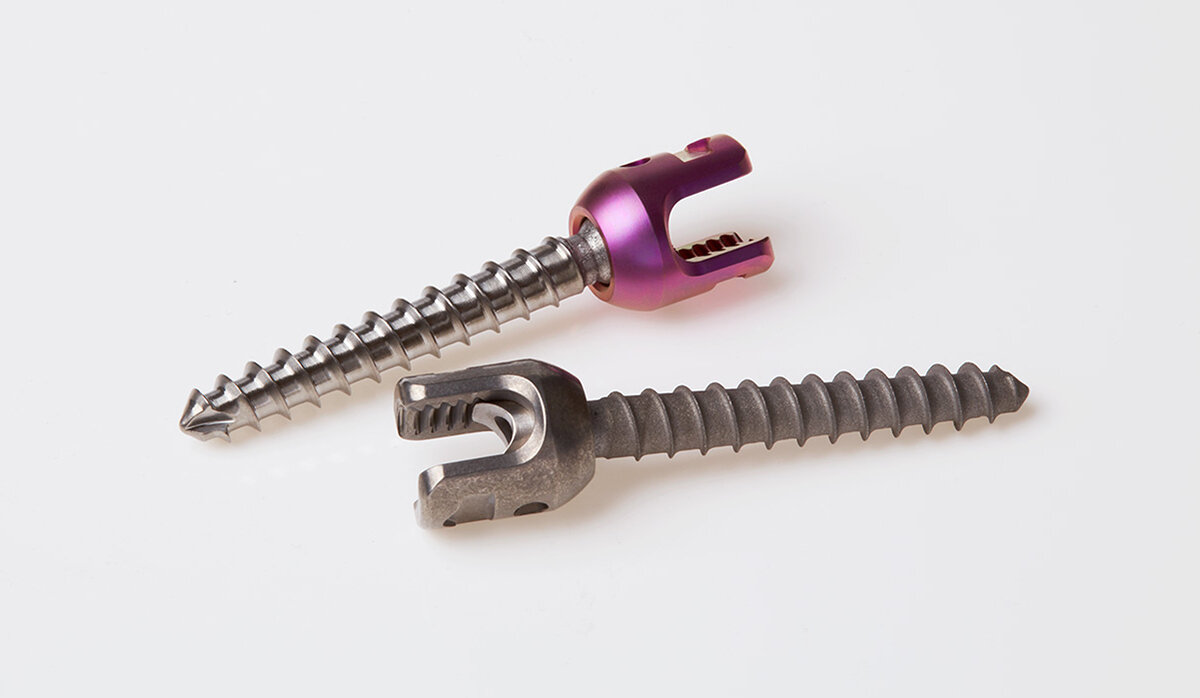

Himed’s MATRIX MCD® (Micro-Crystalline Deposition) technology tackles these challenges with a biocompatible, apatitic abrasive process. Key features include:

- Apatitic abrasive media: Uses calcium phosphate-based particles, mimicking bone’s natural mineral composition.

- Non-destructive precision: Removes surface irregularities without damaging delicate 3D-printed structures.

- Enhanced bioactivity: Creates a microscopically textured surface that promotes bone cell adhesion and growth.

MATRIX MCD® involves tumbling implants in a controlled environment with the apatitic abrasive media, which eliminates trapped powder, polishes rough edges, and deposits a nano-layer of osteoconductive calcium phosphate—boosting the implant’s ability to fuse with bone.

Comparison with Traditional Methods

|

Method |

MATRIX MCD® |

Traditional Techniques |

|

Surface Finish |

Smooth, uniform, and bioactive |

Irregular, risk of over-polishing |

|

Complex Geometries |

Effective on lattices and internal channels |

Struggles with intricate designs |

|

Contamination Risk |

Calcium phosphate media is biocompatible |

Grit media may leave harmful residues |

|

Osseointegration |

Accelerated by bioactive coating |

No inherent bioactivity |

|

Process Time |

Efficient, automated workflow |

Labor-intensive manual polishing |