Understanding STL Files

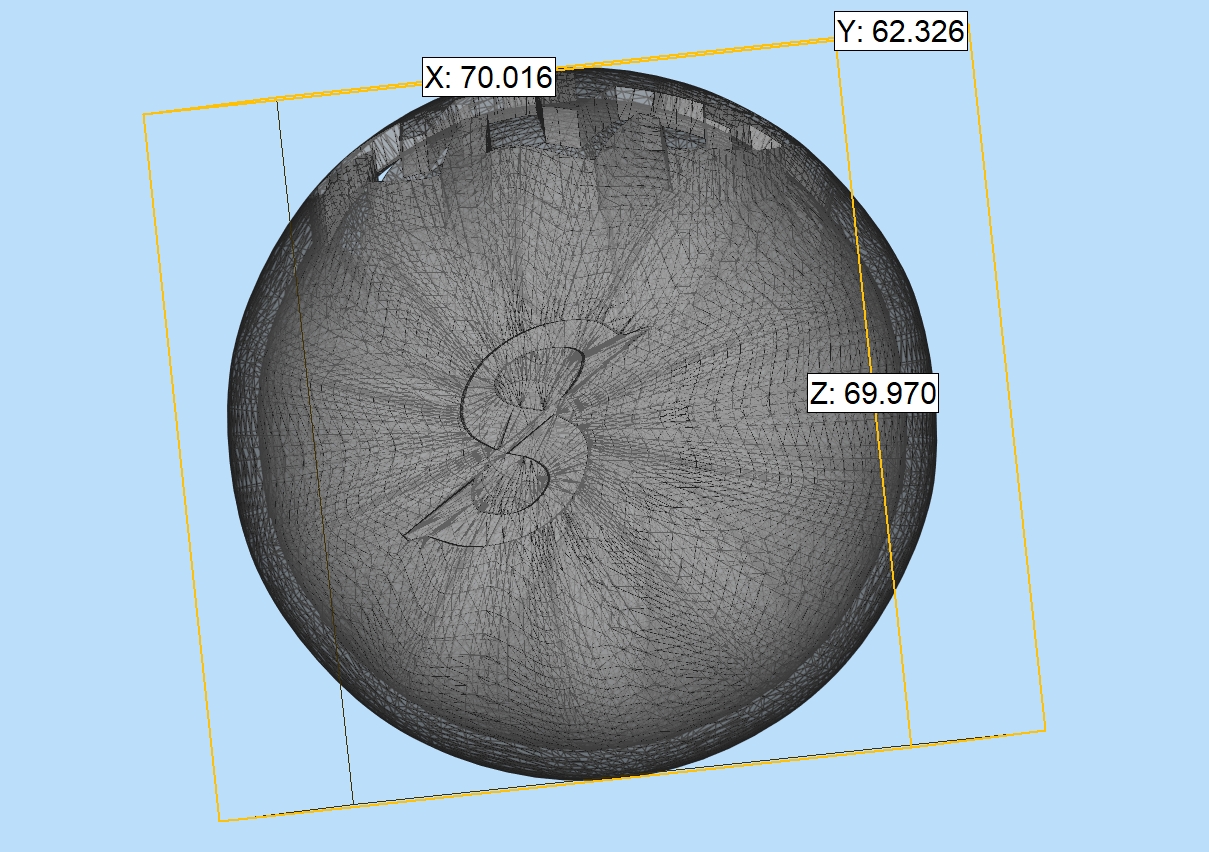

STL files, standing for "stereolithography" or "Standard Tessellation Language," are one of the most common file formats used in 3D printing. STL files represent 3D objects by breaking down their surfaces into a series of interconnected triangles.

An STL file contains only the geometry of a 3D model without any color, texture, or other attributes.

When working with STL files, you'll need to use reliable software tools for viewing, editing, and repairing the files because issues such as non-manifold edges, holes, and intersecting triangles can lead to printing problems, including reversed prints.

Why is STL files printing in reverse?

Reason 1: Mirroring in Slicer Software

One of the most common reasons for STL files printing in reverse is the mirror setting in your slicing software. Slicer software, such as Cura, PrusaSlicer, or Simplify3D, will convert your 3D model into a series of layers that your printer can read. During this process, if the mirror option is enabled, it can flip the model along the specified axis and cause reverse printing. Mirroring can be intentional for a specific design, or it can be an unintentional default.

Solution: To avoid this, double-check the mirror settings in your slicing software before starting to print.

Reason 2: Incorrect Orientation

Incorrect model orientation is another common problem. When preparing an STL file for printing, it is critical to ensure that the model is oriented correctly in your slicing software. The default orientation of the model may not match the intended printing orientation and lead the model to print in reverse or upside down.

Solution: Reviewing and adjusting the orientation in your slicing software can prevent this problem. Besides, pay attention to the axes and make sure the model is properly aligned with the printer's build platform.

Reason 3: File Import Issues

File import issues can also cause STL files to print in reverse. When you import STL files from different CAD software or repositories, the file's orientation data may be interpreted differently. Some software may handle the coordinate system differently.

Solution: It is critical to ensure coordinate system consistency between the design software and the slicing software.