How do 3DSPRO and Malnatt work together?

3DSPRO

3DSPRO is committed to pushing the boundaries of 3D printing services and providing innovative and comprehensive solutions to support businesses and individuals. We offer 3D printing solutions, including DLP, SLA, SLS, MJF, and metal 3D printing. In addition, we have 3D+ solutions with over 50 surface treatments to meet your needs. More importantly, 3DSPRO's AI-empowered quotation system provides customers with a seamless experience. 3DSPRO has a strong focus on customer satisfaction, ensuring customers have the tools and knowledge they need to turn their ideas into reality.

Malnatt

Malnatt is a unique brand that combines tradition with innovation. Malnatt specializes in creating functional smoking pipes, but not just any pipes. These are 3D-printed, allowing for an unprecedented level of detail and customization. Malnatt's mission is to provide its customers with a unique smoking experience, one that is enhanced by the intricate designs and superior functionality of its 3D-printed functional smoking pipes.

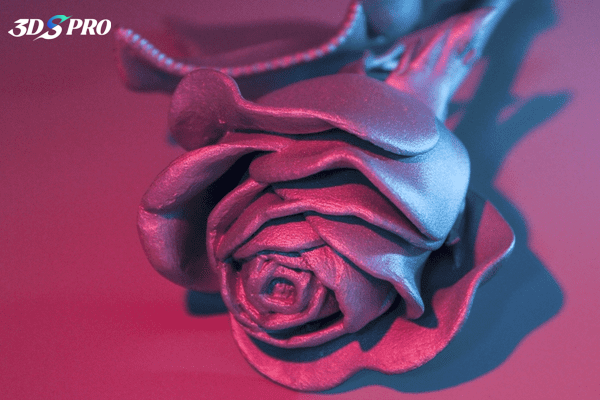

Image Source: Malnatt

3DSPRO Helps Malnatt Craft Unique Smoking Pipes

The collaboration between 3DSPRO and Malnatt is a perfect example of how technology can enhance traditional crafts. Malnatt creates extraordinary designs for smoking pipes, while our comprehensive 3D printing solutions allow Malnatt to create pipes that are not only functional but also works of art. Each pipe is meticulously designed and 3D printed, resulting in a product that is as unique as the person using it.

Tailored Solutions for Exquisite Results

● 3D Printing Technologies Used: SLS, SLM

● Materials Used: Nylon PA 12, Stainless Steel SS316L, Aluminum AlSi10Mg

● 3D+ Solution: Vapor Smoothing (AMT PostPro vapor smoothing systems)

Understanding the intimate contact these pipes have with their users, we prioritize safety and durability. Our recommendation of biocompatible materials, coupled with our professional 3D+ solution, ensures each pipe withstands heat and stands the test of time. Nylon PA 12 serves as the chosen printing material, while vapor smoothing refines the surface, enhancing the experience for Malnatt’s customers.

Precision in Production

Our 3D+ solution is meticulously monitored to preserve every intricate detail during vapor smoothing. We’ve streamlined production and post-processing to meet Malnatt’s ambitious launch timelines, demonstrating our commitment to empowering startups and innovators in harnessing the potential of 3D printing.

Guaranteed Quality Across the Board

Navigating the complexities of manufacturing, we meticulously align product sets with their design specifications and 3D models, ensuring flawless assembly and impeccable quality. From design to material selection, through the 3D printing journey and beyond, we uphold the highest standards.

Empowering Innovation at Every Step

At 3DSPRO, we champion the pioneers of hardware innovation. Offering Malnatt competitive pricing reflects our dedication to overcoming the challenges of producing small-scale, low-volume items without compromising on quality. Our services extend beyond production, aiding in the validation of product aesthetics and functionality and providing market insights. We stand as a steadfast ally to small and medium-sized enterprises, guiding them to master 3D printing.

Product Quality Inspection at 3DSPRO

Malnatt 3D-printed Smoking Pipes

Product Lineup

Malnatt's product lineup consists of four distinct 3D-printed smoking pipes: The First, Cooler X, Cooler Y, and Voronoy. The exterior of the bowl is crafted from AlSi10Mg, an aluminum alloy known for its durability and lightweight properties. The interior, on the other hand, is made from 316/L stainless steel, chosen for its safety, resistance to heat, and corrosion. These two materials are expertly interlocked, ensuring a seamless fit. Complementing the bowl is the mouthpiece, which is fabricated from PA12 nylon, which has outstanding mechanical properties and offers both strength and flexibility.

Each product has its unique aesthetic appeal, with the polished material giving a more "precious" finish, while the matte offers a more "industrial" look. Despite the aesthetic differences, all four products maintain high quality, excellent finishing, and well-defined engraved details, thanks to the superior metal powder used in the 3D printing process.

The First

Image Source: Malnatt

Inspirations

'The integration of 3D printing technology with traditional slow-smoking methods was inspired by a passion for technology and a background in graphic design.' said Mirko, founder of Malnatt. The discovery of affordable 3D printing options and the shift from 2D to 3D design software opened up new possibilities for Mirko. With the exploration of various materials in 3D printing and the challenge of creating a unique smoking pipe for a family member, the most attractive option to combine slow smoking and 3D printing has emerged.

Cooler X

Image Source: Malnatt

Challenges

Designing 3D models for pipes, Mirko has overcome several challenges.

One of the biggest challenges was creating holes and cavities that were minimally affected by support. Similarly, achieving the correct balance in the bowl's thickness was difficult. Too thin, and the heat wouldn't dissipate; too thick, and the pipe would be heavy and uncomfortable.

Besides, the initial prototypes for pipe bowls made from 100% AlSI10Mg aluminum faced criticism over potential toxicity when smoked, which led to a material switch to Stainless Steel for the inner bowl, which presented a new challenge: interlocking two different materials with different tolerances while keeping them sealed without the use of glue or soldering.

These obstacles were addressed and overcome through trial and error. 3D printing undoubtedly brought benefits to the production process and materials choices, including the ability to create new shapes and produce single, unique pieces.

Cooler Y

Image Source: Malnatt

Customer Feedback

While the pipes have not yet been sold, they have been tested by skilled and "famous" pipe smokers. The feedback has been overwhelmingly positive, with testers praising the neutrality of the pipes, which allows every tobacco to taste different, unaffected by briar. Aesthetically, the pipes have received plenty of compliments, particularly from international pipe enthusiasts. The weight of the pipes, at 70 grams compared to an average of 40 grams, was noted as a downside.

Voronoy

Image Source: Malnatt

Design or Printability?

The balance between design and printability in 3D printing is a constant topic of discussion. The process of creating a 3D-printed object involves a delicate interplay between the artistic vision (design) and the technical constraints (printability).

However, for Mirko and his team at Malnatt, the emphasis is decidedly on the design aspect. The creative concept and the idea behind each piece take precedence over its printability. This approach stems from the belief that these items, being objects of pleasure, should not be compromised. If an idea is not printable in its original form, it won’t be realized.

This philosophy underscores the importance of design integrity in Malnatt’s work. The focus is on creating unique, aesthetically pleasing smoking pipes that reflect the brand’s commitment to innovation and quality. The printability of the design is a secondary consideration, a challenge to be addressed rather than a limiting factor.

Image Source: Malnatt

Build Confidence in 3D-printed End-use Parts

3D printing enables the production of end-use parts that are both functional and aesthetically pleasing. In the case of Malnatt’s smoking pipes, these are not just prototypes but final products.

Indeed, the transition from traditional manufacturing methods to 3D printing for end-use parts can raise several concerns.

1. Functionality and Strength: 3D-printed parts can be as functional and strong as those produced by traditional methods. The key lies in the design process and the choice of material. For instance, Malnatt’s smoking pipes are made from durable materials like AlSi10Mg aluminum alloy and 316/L stainless steel, ensuring strength and functionality.

2. Food Safety: The safety of the materials used is crucial when it comes to items that come into contact with food or are used for consumption, like smoking pipes. In the case of Malnatt, the use of 316/L stainless steel, known for its corrosion resistance and food-safe properties, addresses this concern.

3. Practicality and Durability: 3D-printed parts can be designed for practicality and durability. By choosing appropriate materials and using precise printing techniques, 3D-printed parts can withstand daily use. Malnatt’s smoking pipes, for example, are not only aesthetically pleasing but also built to last, offering a unique smoking experience over time.

3D printing for end-use parts may raise questions, but many solutions, such as careful design, material selection, and printing processes, can address these concerns. 3D printing can produce end-use parts that are functional, safe, and durable.

Image Source: Malnatt

3D Printing Services Benefit EVERYONE

3D printing has ushered in a new era of manufacturing, benefiting everyone involved, from designers and manufacturers to end users.

For Designers

3D printing provides designers with a platform to bring their most innovative ideas to life. It allows for rapid prototyping, enabling designers to test and refine their designs more efficiently. Furthermore, it offers unparalleled design freedom, allowing for the creation of complex geometries that would be difficult, if not impossible, to achieve using traditional manufacturing methods.

For Manufacturers

3D printing offers the advantage of cost-effective production for small batch sizes for manufacturers. It eliminates the need for expensive tooling and molds, making it economically viable to produce small quantities of a product. Moreover, it allows for on-demand production, reducing inventory costs and waste.

For End-Users

End-users reap the benefits of 3D printing's customization. Products can be customized to individual needs and preferences, thereby increasing user satisfaction. Additionally, 3D printing can produce lightweight yet strong products, improving functionality and user experience.

For the Environment

3D printing also has potential environmental benefits. It is an additive process, meaning it only uses the material necessary to create the part, reducing waste. Besides, digital files for 3D printing can be transmitted electronically, reducing the need for physical transportation and its associated environmental impact.

3D printing services offer significant benefits to everyone involved in the product lifecycle. By enabling rapid prototyping, design freedom, cost-effective small-scale production, customization, and potential environmental benefits, 3D printing is a game-changer in the manufacturing industry. As the collaboration between 3DSPRO and Malnatt, 3D printing has the potential to revolutionize not just manufacturing but also our everyday lives.