Keeping your 3D printer bed clean is essential for successful prints and prolonging the life of your build surface. A dirty or poorly maintained bed can lead to adhesion issues, warping, or failed prints. This guide will walk you through how to properly clean and care for your 3D printer bed.

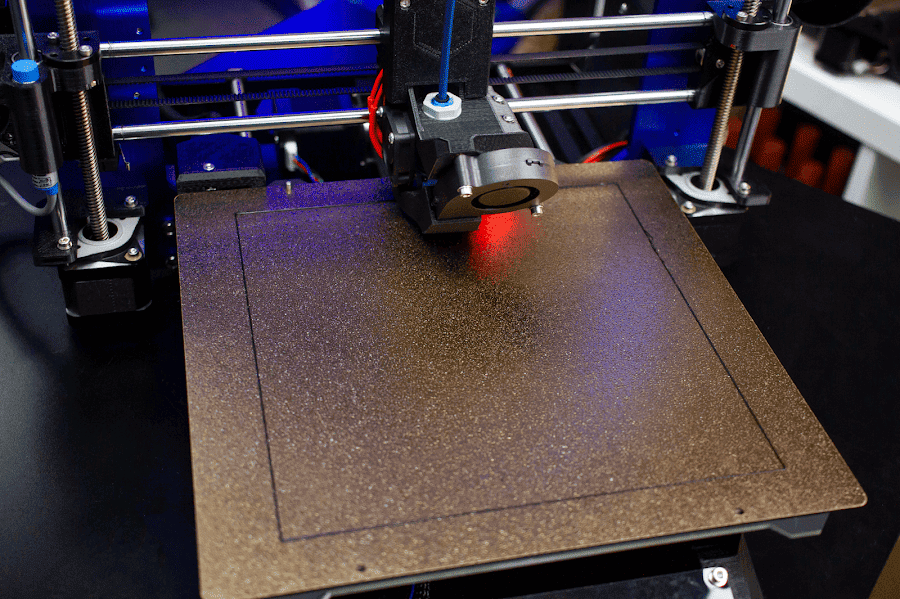

Image Source: MatterHackers

Types of Print Beds and Their Specific Needs

Different 3D printer beds require different cleaning methods. Knowing your bed type will help you avoid damage and clean more effectively.

1. Glass Beds

Glass beds are popular for their flatness and durability. They are often used with adhesives like glue sticks or hairspray. Cleaning them is relatively straightforward.

• Cleaning Tip: Use isopropyl alcohol (IPA) or warm soapy water with a non-abrasive cloth. Avoid sharp scrapers unless necessary to remove stuck prints.

2. PEI Sheets (Polyetherimide)

PEI is known for excellent adhesion without adhesives. However, it can degrade over time with harsh cleaning.

• Cleaning Tip: Wipe with IPA regularly. Use gentle abrasion like fine steel wool occasionally to restore grip.

3. Magnetic Flexible Build Plates

These consist of a magnetic base and a removable flexible sheet, often PEI-coated or textured.

• Cleaning Tip: Remove and clean the sheet with IPA or dish soap. Avoid bending too aggressively.

4. BuildTak or Similar Surfaces

BuildTak is a proprietary surface that provides strong adhesion, but it's sensitive to wear.

• Cleaning Tip: Clean with mild soap and water. Avoid solvents like acetone or IPA, as they can damage the surface.

Tools and Materials Needed

1. Isopropyl Alcohol (90% or higher): Dissolves residue and grease.

2. Microfiber Cloths: Non-abrasive and perfect for wiping surfaces.

3. Plastic or Silicone Scraper: Helps remove stuck prints without scratching.

4. Warm Water and Dish Soap: Great for general cleaning, especially glass and BuildTak.

5. Acetone (for glass only): Removes stubborn ABS residue but should be used cautiously.

6. Fine Steel Wool (for PEI sheets): Helps restore surface texture.

7. Nitrile Gloves (optional): Keeps oils from your fingers off the bed.

Maintenance Tips

|

Tip |

Details |

|

1. Clean Regularly |

Clean your print bed after every few prints to prevent buildup of oils, dust, and filament residue. |

|

2. Avoid Touching the Bed |

Fingerprints introduce oils that hinder adhesion. Handle the bed by the edges or wear gloves. |

|

3. Watch for Adhesive Buildup |

If you use glue sticks or hairspray, clean the surface every few prints to avoid thick residue layers. |

|

4. Re-level After Cleaning |

Always re-level the bed after a deep clean or any significant handling to maintain print accuracy. |

|

5. Keep It Cool |

Let the bed cool completely before cleaning to avoid warping or cracking, especially on glass beds. |

Common Mistakes to Avoid

1. Using Abrasive Cleaners on PEI or BuildTak: These can permanently damage the surface.

2. Scraping with Metal Tools: Unless absolutely necessary (and only on glass), metal tools can gouge or scratch.

3. Over-cleaning with Acetone: Only use acetone on bare glass and sparingly. On other surfaces, it can melt or warp the material.

4. Skipping Bed Maintenance: Neglecting to clean the bed is one of the leading causes of failed prints and surface wear.

5.Using Excessive Force: Being too rough can damage clips, warp beds, or peel adhesive surfaces.

When to Replace Your Build Surface

1. Permanent Adhesion Problems: If prints consistently won’t stick even after cleaning.

2. Visible Damage: Scratches, gouges, or peeling layers.

3. Warping or Bubbling: On magnetic or sticker-based beds, these are signs of breakdown.

4. Inconsistent First Layers: If you're always adjusting your Z-offset or re-leveling with no improvement, the surface might be uneven or degraded.

*Pro Tip: Keeping a spare build surface on hand can reduce downtime and stress when issues arise.

COMMENTS

- Be the first to share your thoughts!