What is vibratory smoothing?

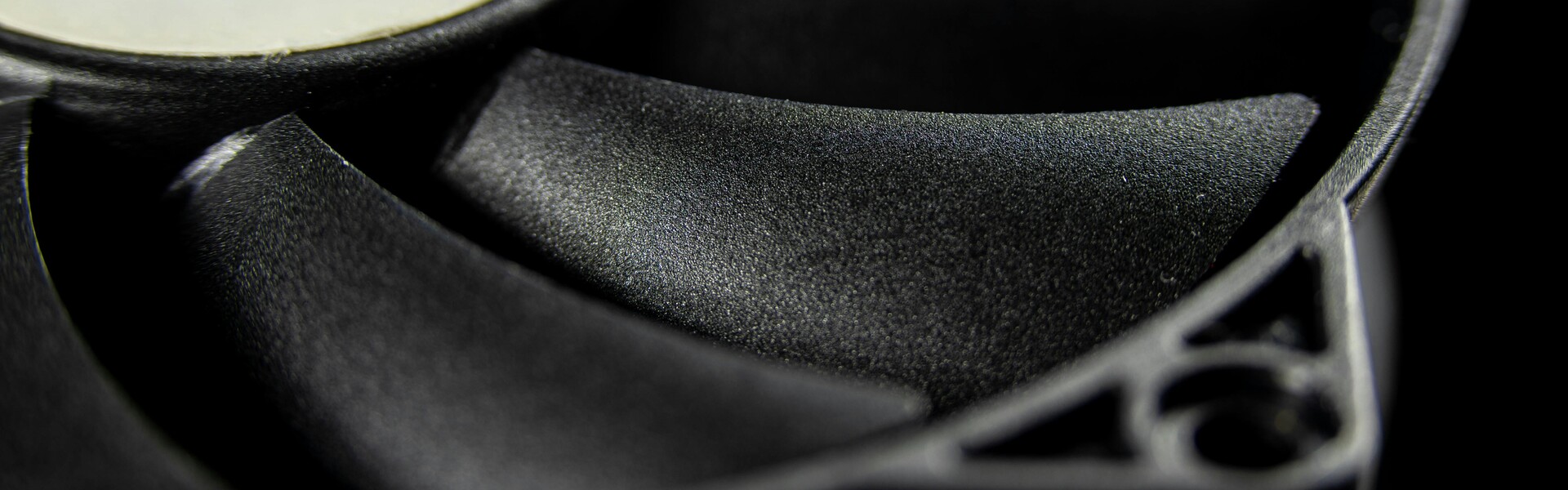

Vibratory smoothing is a post-processing technique used to improve the surface finish of 3D printed plastic parts.

The process involves placing the parts in a vibratory machine filled with abrasive media, such as ceramic or plastic pellets. As the machine vibrates, the media gently grinds against the parts, effectively smoothing out layer lines and surface imperfections.

Vibratory smoothing provides a uniform, polished finish, enhancing both the aesthetic appeal and functionality of the parts.

It is particularly useful for batch processing, making it an efficient method for achieving high-quality surfaces on multiple parts simultaneously.