3 Days/5 Days/7 Days

200*125*210mm

± 200μm or 0.2%mm

12 (Formlabs Printing System)

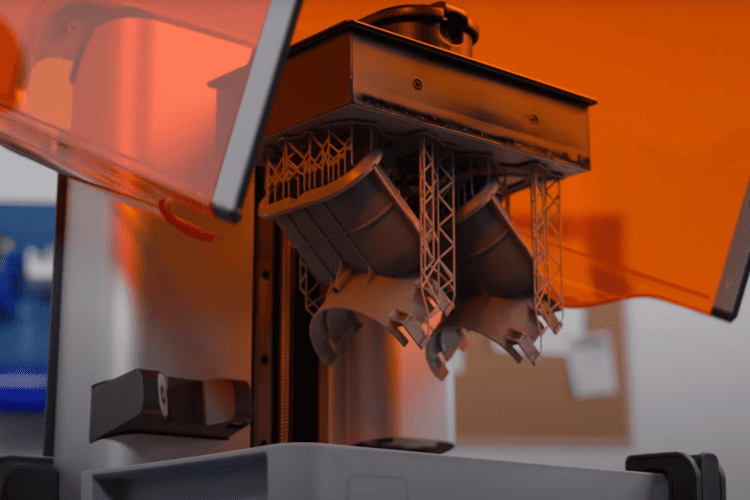

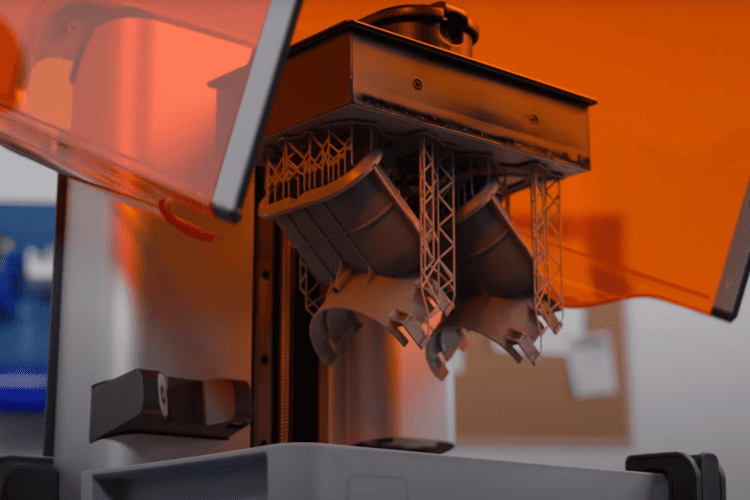

Image Courtesy of Formlabs

Image Courtesy of Formlabs

Image Courtesy of Formlabs

Image Courtesy of Formlabs

LCD 3D printing, also known as Masked Stereolithography (MSLA), is a resin-based 3D printing process that uses a high‑resolution liquid crystal display to selectively block or transmit UV light, curing entire layers of photopolymer resin at once with exceptional precision.

LCD produces parts with fine details, sharp edges, and smooth surface finishes that often require minimal post‑processing, making it ideal for intricate geometries and high‑fidelity prototypes. LCD 3D printing is widely used in custom dental models, jewelry casting patterns, miniature figures, engineering prototypes, etc.

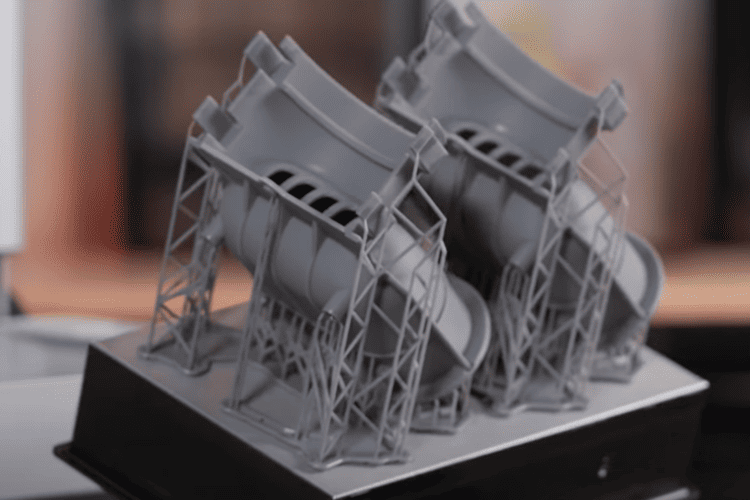

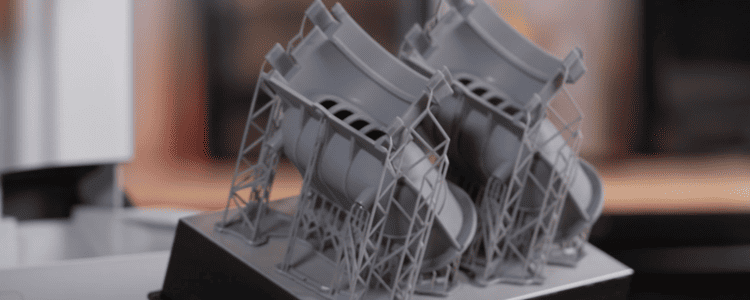

Image Courtesy of Formlabs

Image Courtesy of Formlabs

Here are what we do for LCD 3D printing processes at 3DSPRO:

Import files on the MSLA 3D printers.

Import files on the MSLA 3D printers. Optimize build chamber space.

Optimize build chamber space. MSLA 3D printers operating.

MSLA 3D printers operating. Take the printed part out of the build chamber.

Take the printed part out of the build chamber. Washing.

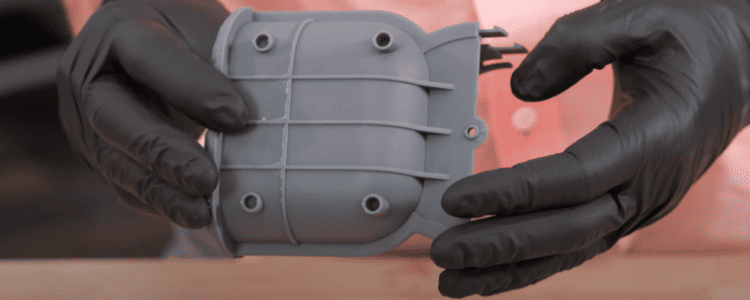

Washing. Supports removal.

Supports removal. Curing.

Curing. Send printed parts to further post-processing (optional).

Send printed parts to further post-processing (optional). Quality inspection.

Quality inspection. Packing and shipping.

Packing and shipping. Image Courtesy of Formlabs

Image Courtesy of Formlabs

Image Courtesy of Formlabs

1. High Detail and Accuracy: Capable of reproducing intricate geometries, sharp edges, and fine texturing with pixel-level precision, making it ideal for complex parts and detailed models.

2. Smooth Surface Finish: Produces parts with minimal visible layer lines and excellent surface quality straight off the build plate, reducing the need for extensive post‑processing.

3. Good Mechanical Properties: When paired with the right engineering or tough resins, LCD‑printed parts can achieve strong tensile strength, impact resistance, and durability suitable for functional testing and end‑use applications.

Image Courtesy of Formlabs

1. Build Volume Constraint: Most consumer and prosumer LCD printers have relatively small build areas, limiting the size of single‑piece prints and making large objects dependent on multi‑part assembly.

2. Potential “Screen Door” Effect: The pixel grid of the LCD panel can sometimes leave faint patterns on the surface of prints, slightly reducing visual smoothness on certain geometries.

3. Post‑Processing Requirements: Prints must be washed (usually in isopropyl alcohol) and UV‑cured after printing, adding time, equipment needs, and labor to the workflow.

Image Courtesy of Formlabs

Image Courtesy of Formlabs

3DSPRO collect cookies on your computer to provide more personalized services to you. By using this website, you consent to the cookies we use and our Privacy Policy

Accept