HOT Award Trophy: A 3D-Printed Masterpiece

Designer: Tim Murphy

Company: GOTIM Labs

Learn More on MoCo Makers and CozyCurvy

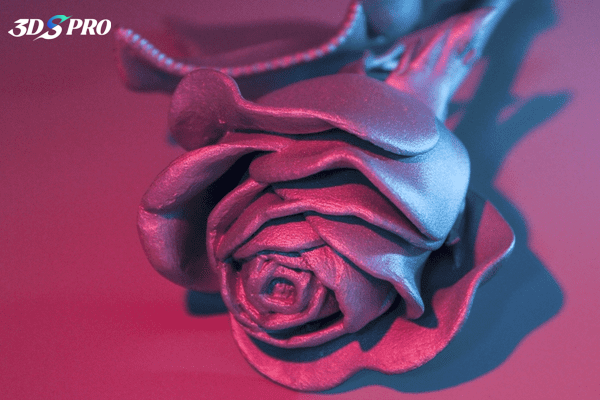

The HOT Award trophy is a 3D-printed masterpiece, ingeniously crafted into spheres and tetrahedrons. It has seven removable parts, allowing the recipient to discover the engraved message upon disassembly. The HOT Award is a trophy beyond the ordinary.

Design Ideas

The trophy represents altruism. The various parts of the internal structure are connected. “The initial idea came to me in a dream. For a couple of weeks, I spent a little time every day visualizing potential designs. I decided to use various relationships between spheres and tetrahedrons to represent aspects of helping others.” shared Tim, the founder of GOTIM Labs.

Original Design of the HOT Award

Unique and Meaningful

Unlike the typical single-entity trophy, this award is a collection of six elements (seven, including the base). When the sphere unfolds, the hidden text is revealed. The surfaces of these words are artfully intertwined and designed to nestle together seamlessly.

The HOT Award trophy is used to reward folks for helping others. “The first recipient was Matthew Zamora,” Tim remarked. Matthew is the leader of MoCo Makers, Montgomery County’s largest DIY tech and science community. He is a software engineer with an educational background in neuroscience and has helped countless folks. For example, without any funding, he is leading a drug discovery team. His team recently published Drug Responses in Plexiform Neurofibroma Type I (PNF1) Cell Lines Using High-Throughput Data and Combined Effectiveness and Potency - PubMed (nih.gov).

“Although we have only issued one award, we will eventually issue several each year. Along with the trophy, we intend to offer a financial award, too,” said Tim.

3DSPRO’s Support for GOTIM Labs

3D Printing Capabilities

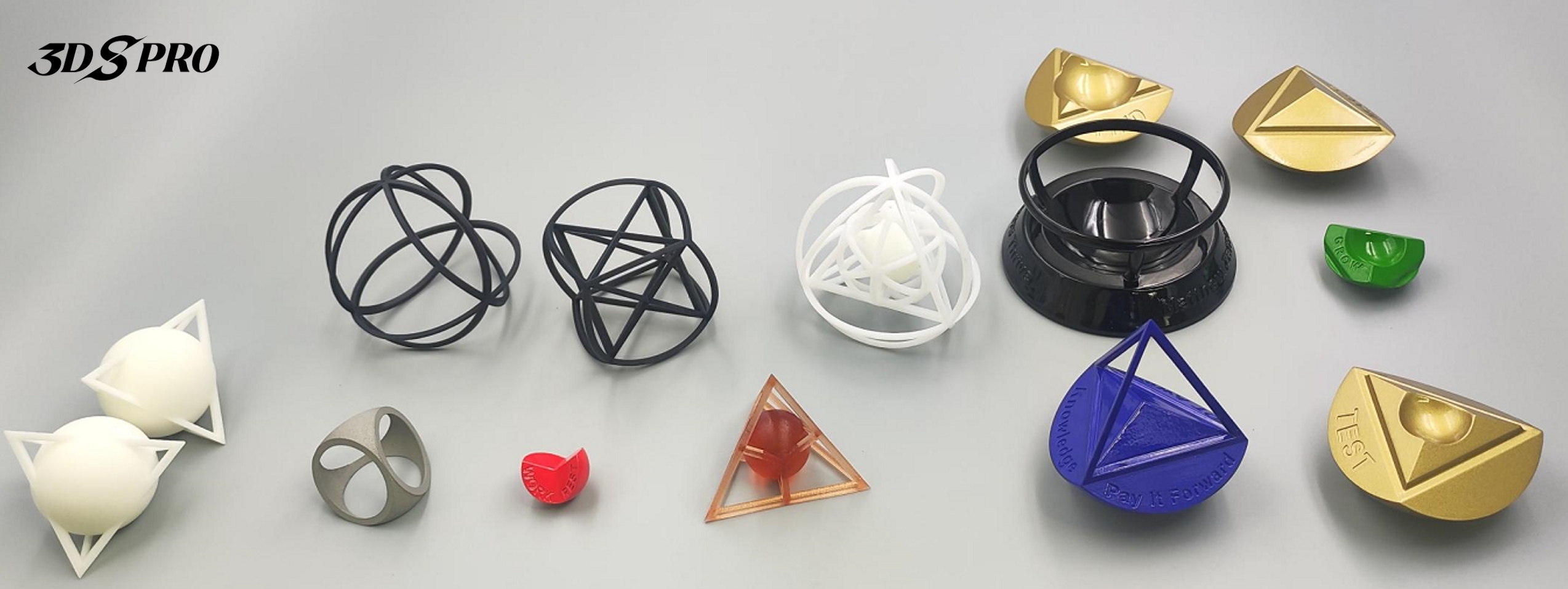

3DSPRO has harnessed a trio of advanced 3D printing methods—SLA, SLS, and SLM 3D printing—to assist GOTIM Labs in crafting an exceptional trophy.

Material Diversity

We provided premium materials, including High-Quality White Resin (SLA), Ultra-Tough Blue Resin (SLA), High-Temperature Resistant Resin (SLA), Nylon PA 12 White (SLS), and Stainless Steel 316L (SLM), enabling GOTIM Labs to create distinct components of the trophy with precision.

Swift Turnaround

Our commitment to highly efficient service is unwavering. With a lead time of just 72 hours, we ensure quality is never compromised.

Enhanced 3D Plus™ Solutions

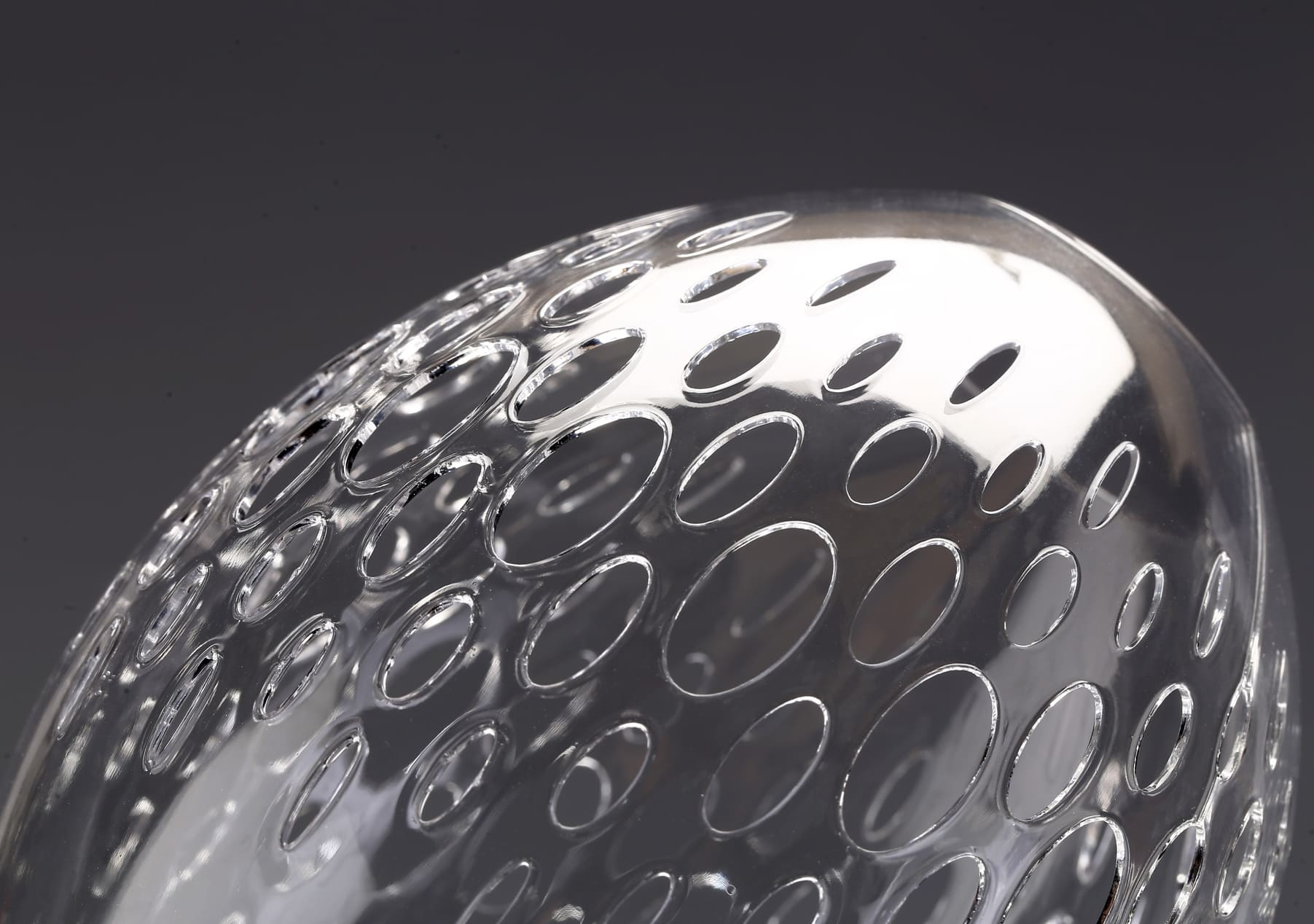

Surface Finish: Glossy Spray Painting

GOTIM Labs required a metallic sheen for their trophy’s surface. Our meticulous post-processing protocol for spray-painted parts consists of sanding, fine sanding, cleansing, priming, drying, spray painting, another round of drying, and thorough inspection. This process guarantees the glossy, metallic finish our client envisioned. Adhering strictly to Pantone color standards ensures the final product matches the original 3D model’s hues. Our use of high-quality primers and paints, coupled with expert technicians, results in a durable, long-lasting, and oxidation-resistant finish. We’re dedicated to preserving the high fidelity and integrity of all 3D-printed parts, even after post-processing.

Flexible Production for Varied Volumes

3DSPRO supports production runs of all sizes, from single pieces to small batches, without imposing minimum order quantities or base prices. This flexibility caters to the needs of individual makers, startups, and established companies. Regardless of part size or order quantity, quality remains critical. GOTIM Labs enjoys the freedom to select any 3D printing technology or material for each part, with no restrictions on size or quantity. Our spray painting services are available for even the smallest parts, accommodating a variety of Pantone colors as specified by the client. By merging our specialized services with the versatility of 3D printing, we offer cost-effective and adaptable solutions that align with the demands of diverse industries.

Unparalleled Customization

While custom parts are commonplace in manufacturing, the extent of customization can vary widely. In this instance, 3DSPRO provided a tailored solution to meet GOTIM Labs’ exacting standards. For instance, to achieve a high-resolution surface finish as requested, we sliced the 3D models with a layer height of 0.05mm, ensuring a smooth and refined appearance. Moreover, we maintained strict tolerances for clearance fits within the trophy’s internal structure, even for non-functional parts. Should any component warp during transit, our commitment to customer satisfaction is such that we will reprint the part at no additional cost.

GOTIM Labs: A Pioneer in Combining Creative Design and 3D Printing

When we discussed how much consideration was given to the printability aspect of 3D printing, Tim remarked, “I have invented and designed various products and have used 3D printers, CNC, and laser machines to make prototypes. I have also made some injected molded parts that required draft angles, etc., so I have a fair idea of what is possible.”

Tim, the founder of GOTIM Labs, brings a wealth of experience in industrial design and manufacturing to the table. As a seasoned and imaginative designer, he excels in crafting both artistic and functional projects. GOTIM Labs prides itself on its ability to tailor designs to meet client specifications while adeptly managing multiple projects in tandem. From innovative Smart Pillows (the CozyCurvy) to the wonderful HOT Award Trophy, Tim infuses a burst of creativity into each endeavor.

To quickly and efficiently bring his vision to life, Tim turned to 3D printing – an area where he is a key figure in the MOCO Makers 3D printing community. Looking at Tim’s track record, it’s clear that he will continue to create a range of creative designs for the 3D printing world.

Feedback from GOMTIM Labs

Regarding the Final Results

“I'd like to say the HOT Award print exceeded my expectations!” “The box arrived undamaged. All parts were well protected within the box. The parts fit beautifully, the award presentation was a success, and everyone loves the colors.”

Regarding the Services

“I like 3DSPRO and will recommend and use your services again.” “I never had a part painted before so I can't compare it with others, but I liked the results.”

Regarding the Comparison

“I have used Shapeways, Protolabs, and others. Discovered you via Craftcloud. You offered good prices and I thought I'd give you a try.”

3D Printing Paves an Easier Way for the Hardware Industry

Compared to traditional manufacturing technologies like CNC machining and injection molding, 3D printing is unique in that its ability to create shapes and complex parts exceeds even the capabilities of 5-axis CNC machines. Its customization capabilities are unmatched by injection molding. While 3D printing is great for prototyping, it may not be well suited for mass production.

As a result, 3D printing opens up a wealth of new opportunities for the hardware industry. Consider the challenge of crafting a trophy with numerous detachable internal structures as a single unit—using CNC machining would be prohibitively expensive, undermining the project’s budget. Injection molding wouldn’t even be a viable option. In contrast, the complex structure of the trophy is readily achievable through 3D printing.

3D printing also supports the creation of end-use functional parts, thereby expanding the scope of applications and scenarios. There is no doubt that hardware industries such as automotive, renewable energy, and even aerospace will greatly benefit (or already benefit) from 3D printing.