The Hidden Flaw Holding Back Metal 3D Printing

For more than three decades, 3D printing has been hailed as the future of manufacturing. From rapid prototyping to custom implants and aerospace components, additive manufacturing promised to reshape how we design and build. Yet despite its revolutionary potential, one stubborn flaw has consistently held metal 3D printing back: porosity.

Porosity refers to the tiny voids and gaps that form within printed metal structures. These microscopic imperfections may seem trivial, but in engineering terms, they are catastrophic. They weaken parts, reduce reliability, and make it nearly impossible to certify 3D printed metals for use in critical applications like jet engines, spacecraft, or medical implants.

The dream of printing strong, reliable, and customizable metal parts has therefore remained just out of reach, until now. Researchers at the École Polytechnique Fédérale de Lausanne (EPFL) have unveiled a breakthrough process that directly addresses porosity and shrinkage, producing dense, ultra‑strong metals and ceramics. Their innovation could mark a turning point in the history of additive manufacturing.

The Porosity Problem in Metal Printing

To understand the significance of EPFL’s work, it’s important to grasp why porosity is such a persistent problem.

Most metal 3D printing methods rely on either powder bed fusion or binder jetting. In powder bed fusion, a laser or electron beam melts layers of metal powder together. In binder jetting, a liquid binder is deposited onto a powder bed, and the resulting “green part” is later sintered in a furnace. Both methods suffer from incomplete fusion, uneven shrinkage, and trapped voids.

The result is a structure riddled with microscopic pores. These pores act like stress concentrators: under load, cracks initiate and propagate from them, leading to premature failure. In aerospace, where safety margins are razor‑thin, or in biomedical implants, where reliability is non‑negotiable, porous parts are unacceptable.

Engineers have tried to mitigate porosity through post‑processing steps such as hot isostatic pressing (HIP), which compresses parts under heat and pressure to close voids. But these steps add cost, complexity, and time, and they cannot always eliminate porosity completely.

The EPFL Solution: From Hydrogel to High Density Metal

The EPFL team, led by researcher Daryl Yee, approached the problem from a completely different angle. Instead of starting with metal powders or resins, they began with something deceptively simple: a hydrogel scaffold.

Hydrogels are water‑based polymers that can be easily printed into complex shapes. Once the scaffold is printed, it is infused with a solution of metal salts. Through a chemical reaction, these salts are converted into nanoparticles that coat the hydrogel’s internal structure.

Here’s where the breakthrough lies: the process is repeated in growth cycles. Each cycle deposits more nanoparticles, gradually building up a dense metallic network within the scaffold. After enough cycles, the hydrogel is burned away in a furnace, leaving behind a pure, dense metal or ceramic structure that faithfully replicates the original printed form.

The “print first, choose material later” approach flips the traditional logic of additive manufacturing. Instead of being constrained by the material during printing, engineers can design the form first and then decide whether it should become iron, copper, silver, or even ceramic.

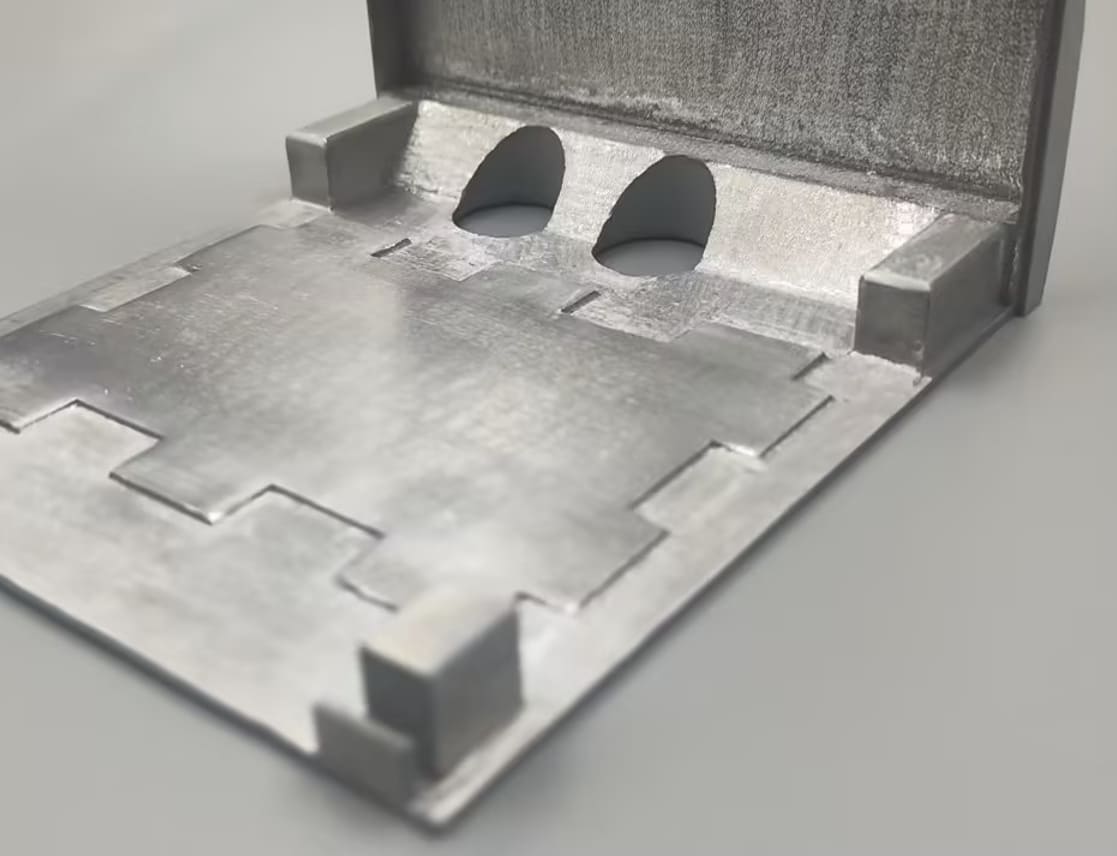

Image Source: EPFL

Denser, Stronger, and More Reliable Structures

The results of this method are striking.

• Porosity Eliminated: The repeated growth cycles fill voids, producing structures with exceptional density.

• Shrinkage Reduced: Conventional polymer‑to‑metal methods shrink by 60–90%, often warping parts. EPFL’s process shrinks by only ~20%, preserving dimensional accuracy.

• Strength Leap: Tests show that the resulting materials can withstand up to 20 times more pressure than those produced by earlier 3D printing techniques.

By solving porosity and shrinkage simultaneously, EPFL’s method produces metals and ceramics that are not only printable but also reliable enough for demanding engineering applications.

From Turbine Blades to Implants

Aerospace

Jet engines and spacecraft require components that are both lightweight and incredibly strong. Porosity has been a deal‑breaker for 3D printed metals in these fields. With EPFL’s method, turbine blades, fuel nozzles, and structural brackets could be produced with the reliability needed for flight.

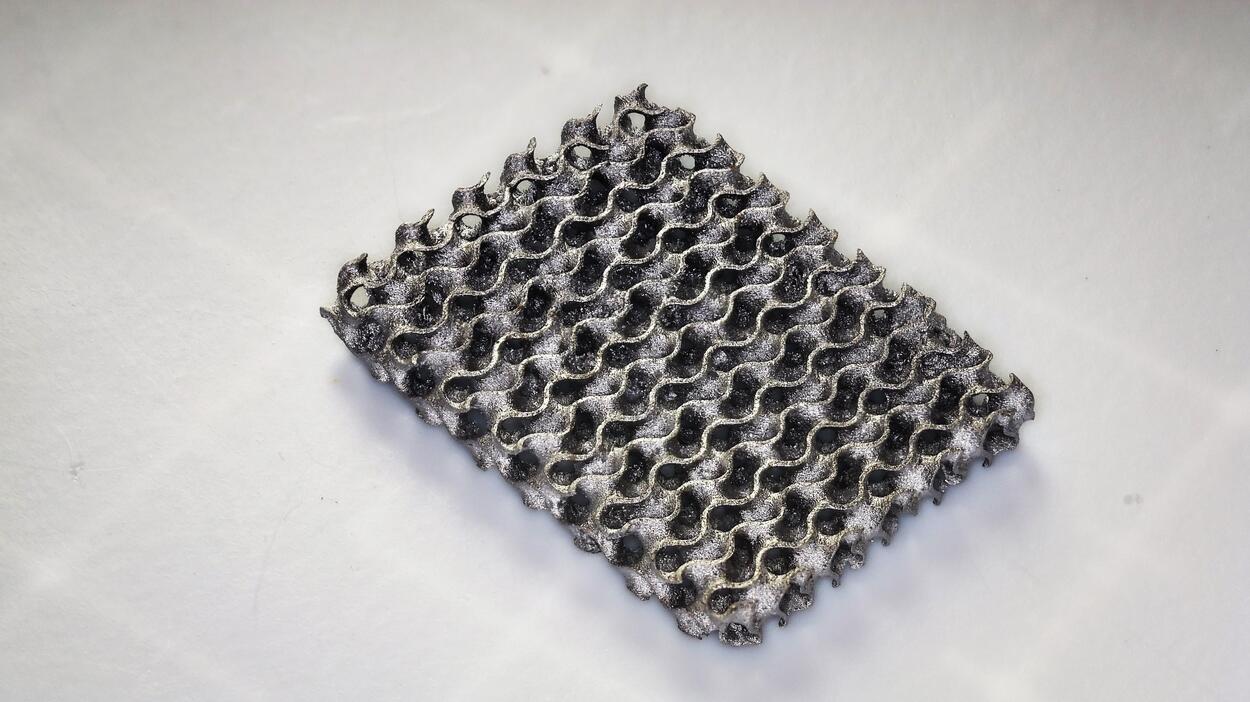

Energy Devices

High‑surface‑area metals are critical for cooling systems, catalytic converters, and energy storage devices. The ability to grow dense, conductive metals into complex geometries could improve efficiency and performance in renewable energy and power generation.

Biomedical Implants

Custom implants tailored to individual patients are one of the most compelling promises of 3D printing. But porous, unreliable metals have limited adoption. EPFL’s process could enable durable, biocompatible implants, from dental prosthetics to orthopedic devices, that last longer and perform better.

Redefining the Rules of Additive Manufacturing

Beyond solving porosity, EPFL’s innovation redefines the very logic of additive manufacturing.

Traditionally, engineers must select a material before printing, which constrains design choices and limits flexibility. With the hydrogel‑based approach, the workflow is inverted: design first, material later. A single hydrogel template could be transformed into iron for strength, copper for conductivity, or ceramics for heat resistance.

The flexibility of such innovation opens the door to multi‑material devices. Imagine printing a single scaffold that is later grown into a hybrid structure: part metal, part ceramic, tailored to specific functional requirements. Such possibilities could revolutionize product design, enabling devices that are lighter, stronger, and more efficient than anything possible today.

Challenges: Scaling the Lab Breakthrough to Industry

Of course, no breakthrough is without hurdles.

1. Scaling Growth Cycles: The repeated infusion and conversion steps are effective in the lab, but scaling them for industrial throughput will require automation and process optimization.

2. Reproducibility and Quality Control: Ensuring consistent density and strength across large batches of parts is essential for industrial adoption.

3. Certification Hurdles: Aerospace and biomedical industries have stringent certification processes. Proving that “grown” metals meet or exceed safety standards will take time and rigorous testing.

4. Cost Considerations: While the process is potentially lower‑cost than powder‑based methods, scaling it economically will depend on material efficiency and cycle times.

These challenges are real, but they are not insurmountable. Many disruptive technologies face similar barriers before reaching widespread adoption.

Porosity Free Manufacturing?

The promise of EPFL’s “grow‑to‑metal” process is profound: a future where porosity is no longer the limiting factor in metal 3D printing. By eliminating voids, reducing shrinkage, and producing ultra‑strong structures, the method could finally deliver on the long‑held dream of reliable, customizable, and versatile additive manufacturing.

If scaled successfully, this approach could transform industries from aerospace to medicine, ushering in an era where machines and devices are not merely printed but grown. The implications are both technical and philosophical: manufacturing may no longer be about forcing materials into shape, but about cultivating them into form.