What if cancer pills could be engineered like precision machines? That’s the bold vision behind Enzian Pharmaceutics, a startup born from MIT research, which is using 3D printed fibers to transform how oral cancer drugs are delivered.

For decades, oral tablets have been designed around convenience, not precision. They dissolve quickly, flooding the body with high doses of medication that can overwhelm patients with side effects before drug levels crash and lose effectiveness. Enzian’s approach flips this model on its head. By weaving polymers into fibrous microstructures, the company has created tablets that behave more like engineered systems than simple pills.

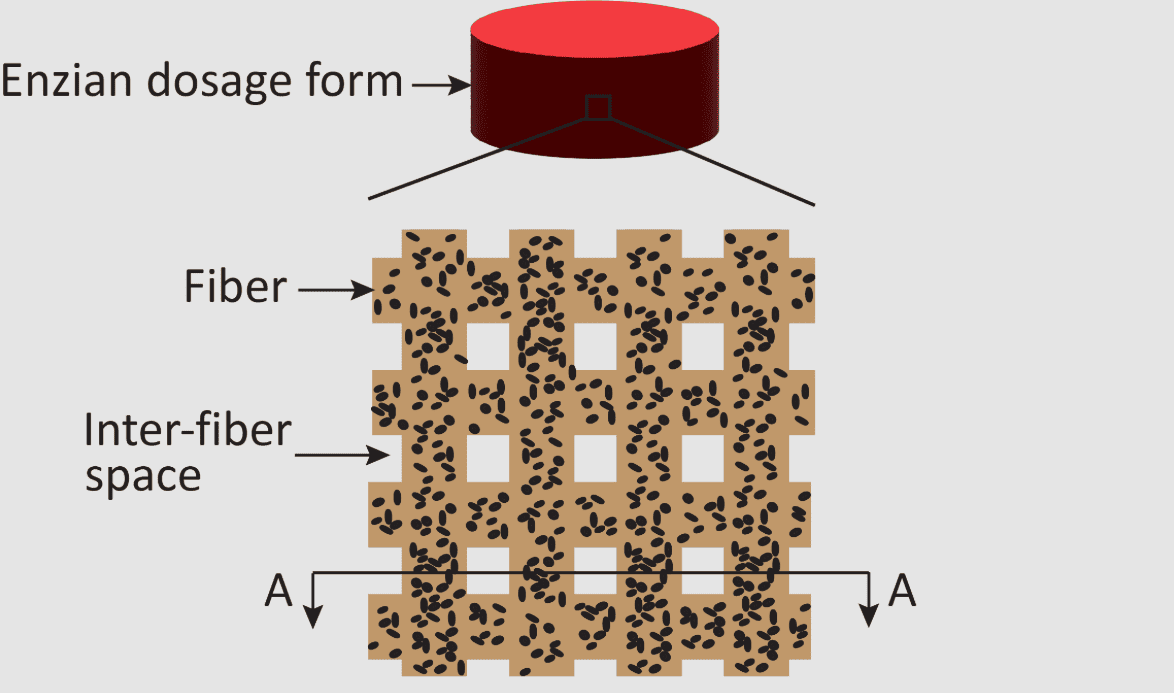

Image Source: Enzian Pharmaceutics

The Problem with Conventional Tablets

Traditional cancer pills dissolve within minutes, releasing their entire payload in a single burst, which creates two major problems:

• Toxic Peaks: drug concentrations can spike up to 50 times higher than intended, causing severe side effects.

• Rapid Clearance: after the spike, drug levels plummet, leaving patients underdosed until the next pill.

For patients, this cycle means discomfort, inconsistent treatment, and difficulty adhering to complex dosing schedules.

The 3D Printed Fiber Solution

Enzian’s breakthrough lies in the geometry of the tablet itself. Instead of compressing powders into a solid pill, the company uses 3D printing to weave polymers into grid‑like fibers.

• Water‑Responsive Design: once swallowed, the fibers absorb fluid and expand into a gel‑like matrix.

• Extended Residence Time: the gel resists rapid breakdown, keeping the tablet in the stomach for 12–24 hours.

• Controlled Release: as the gel slowly erodes, the drug is released in steady, predictable doses.

The result is a pill that acts less like a dissolving lump of powder and more like a precision‑engineered delivery system.

Engineering Medicine Rather Than Manufacturing Pills

What makes this breakthrough transformative is not only the material but also the mindset:

1. Design As Therapy: Tablets are no longer passive carriers of chemicals. They are active systems, designed with intention, geometry, and function in mind.

2. Patient‑Centric Innovation: For cancer patients, this means smaller doses, fewer side effects, and once‑daily convenience. The pill adapts to the body, rather than forcing the body to adapt to the pill.

3. Beyond Oncology: The same design principles could be applied to chronic diseases, infectious conditions, and even personalized medicine, where tablets are tailored to an individual’s biology.

4. A New Pharmaceutical Paradigm: 3D printing becomes a design language for biology, enabling therapies that are as carefully crafted as aerospace components or microchips.

3D printing is often celebrated for its role in aerospace, automotive, and consumer products. But its most profound impact may come from something as small as a pill. By reimagining tablets as engineered fiber systems, Enzian Pharmaceutics is charting a path toward safer, more effective, and more humane cancer treatments.