Reducing or eliminating support structures is one of the fastest ways to cut print time, save material, improve surface finish, and simplify post-processing. Done well, support-aware design keeps parts strong and functional while minimizing the annoyances that come with ripping, sanding, or chemically dissolving supports.

What Creates the Need for Supports

Supports are required whenever a printer cannot reliably deposit or solidify material in mid-air. The common root causes are:

Overhangs and horizontal ledges. Layers with no underlying material fail or sag. Printers can handle some angle of overhang (a rule-of-thumb for many FDM machines is up to 45° from horizontal), but steeper or flat overhangs often need support.

Bridges and long spans. A short bridge may print fine, but long spans will droop unless supported or designed as arches.

Islands and isolated features. Small features printed before their surrounding structure can lack thermal support and curl or delaminate.

Process limitations. Layer adhesion, cooling, resin suction forces, powder binding behavior, and thermal stress all influence whether a region needs support.

Orientation constraints for function. Functional surfaces or mechanical interfaces sometimes force an orientation that increases support need.

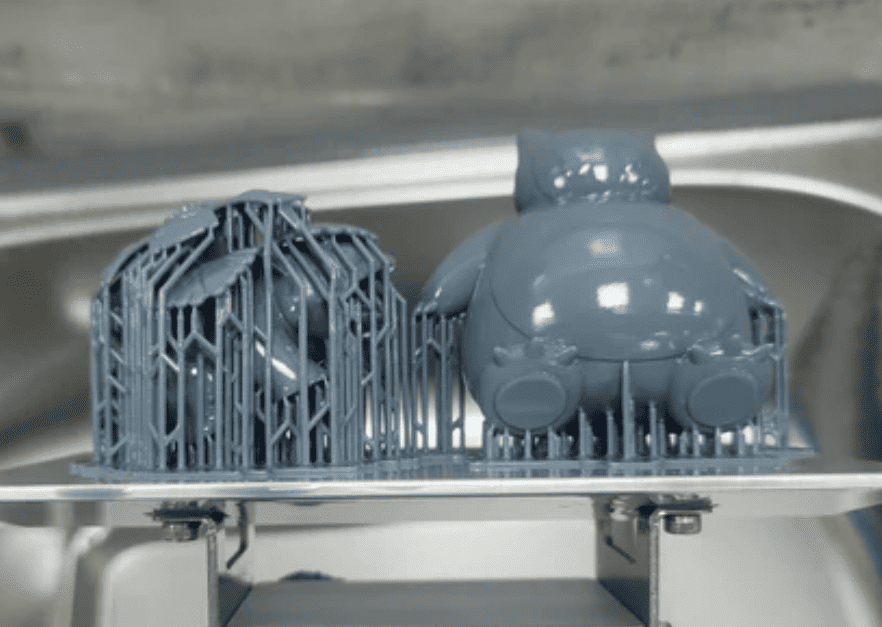

Image Source: Phrozen

Design Principles to Reduce Supports

1. Favor self-supporting angles and slopes. Replace horizontal ledges with sloped faces. Gentle slopes let layers rest on previously printed material and avoid steep overhangs.

2. Break flat overhangs into ramps or steps. A smooth ramp or stepped façade is printed without supports; each step stays within safe overhang limits.

3. Use fillets and chamfers strategically. Fillets distribute stress and reduce sharp overhang angles; chamfers give an angled surface that is easier to print and cleaner than an abrupt ledge.

4. Split complex parts into assemblies. If a functional geometry creates unavoidable overhangs, design the part to print in multiple pieces and assemble with fasteners, snaps, or adhesives.

5. Place critical features upward. Put visible or load-bearing surfaces in orientations that avoid support contact points.

6. Use internal lattices or ribs instead of large unsupported plates. They maintain stiffness while removing unsupported flat surfaces.

7. Design for access. Ensure tools and solvent can reach support contact points if supports remain necessary.

CAD Strategies and Geometry Patterns

Fillets vs. Chamfers

Use a chamfer when you need a clear, predictable angle for printing; use a fillet if load distribution or aesthetics are the priority. Typical CAD chamfers of 1–3 mm at critical edges often eliminate tiny supports; fillets with radii equal to layer height × 10–30 are useful for smoothing stair-stepping.

Stepped Faces

Replace a 90° overhang with a series of shallow steps or a single slope. Steps can be parametric patterns, so you can rapidly adjust step height.

Arches and Catenary Shapes

Where a bridge is required, an arch is self-supporting and prints better than a flat span.

Perforations and Hole

Large horizontal cavities trap unsupported material. Add vent holes or perforations to break up large plates and allow internal cavities to collapse less.

Sacrificial Tabs and Mouse-Ears

Small, thin tabs that are easy to cut or snap off give orientational support where needed without damaging primary surfaces.

Split Seams and Joining Features

Design registration features into split parts so they assemble cleanly and keep functional geometry intact.

Custom Support Pads

If you must use supports, design pads or bosses that concentrate contact on low-visibility or non-critical areas, this makes cleanup easier and preserves finishes.

Process-Specific Rules

FDM

• Safe overhangs are commonly around 40–60° from horizontal, depending on cooling, material and layer height. Use active cooling and smaller layer heights to extend this.

• Bridges print reliably over short spans. Start by testing bridges in 10–20 mm increments to qualify your material and nozzle.

• Orientation matters. Align layers with load paths when strength matters and rotate to reduce unsupported surfaces for cosmetic areas.

• Use tree or organic supports when possible. They use less material and fewer contact points than dense block supports.

SLA

• Supports are tiny but necessary to resist peeling forces. Slender, well-spaced supports reduce marks but must be strong enough to hold parts during peeling.

• Design drainage holes and orient hollow parts at an angle to avoid trapped resin and suction stress.

• Place support contacts on non-critical faces and add fillets around contact points so they’re less intrusive when removed.

SLS and MJF

• Typically support-free because the unfused powder acts as a support. Your focus is on powder escape, avoiding enclosed cavities that cannot be cleared, and minimizing warping through geometry and packing strategy.

• Design channels or escape holes for trapped powder in complex internal geometries.

SLM

• Supports are structural during the build and for heat conduction. Minimize overhangs but prioritize support design for removal and downstream heat treatment.

• Add access for tooling. Design supports on regions that are machined away or on sacrificial faces.

Common Pitfalls and How to Avoid Them

1. Over-optimizing for zero supports at the cost of function. Don’t weaken a structural feature to avoid supports. If a function requires a flat, print it smartly. Orient, use soluble supports, or split the part.

2. Hiding supports inside assemblies where they can’t be removed. Always verify access for support removal and for trapped materials.

3. Ignoring material and printer capabilities. A geometry printable on one machine or filament may fail on another. Keep small test coupons to qualify settings quickly.

4. Putting support contact on visible surfaces. Plan support contacts on internal or low-visibility faces and use small mushroom-style contacts to ease removal.

5. Not prototyping orientation options. The wrong orientation can multiply support volume. Use slicer previews and several orientation trials before committing.