What is 3D concrete printing?

3D concrete printing (3DCP) is an innovative construction technology that uses robotic systems to build structures out of concrete layer by layer. Unlike traditional construction methods, 3DCP eliminates the need for formwork, reducing material waste and allowing for greater design flexibility.

The process begins with a computer-aided design (CAD) file that instructs the printer on the structure’s layout. Printers used in 3DCP are typically of two main types: gantry systems and robotic arm systems. Gantry systems are suitable for large-scale projects and operate in a fixed setup, while robotic arm systems offer more flexibility and precision, albeit usually on a smaller scale.

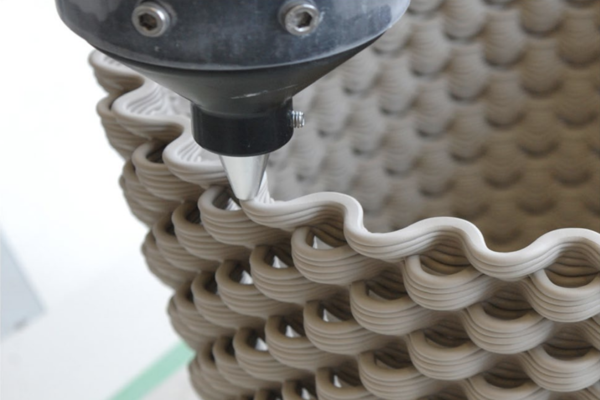

One of the most compelling applications of 3DCP is in the construction of houses. A 3D-printed concrete house is created using specially formulated concrete mixtures, which are extruded through a nozzle to form the walls and other structural elements of the house layer by layer. It can significantly speed up the construction process, reduce labor costs, and allow for complex architectural designs that are difficult to achieve with traditional methods.

Image Source: Mighty Buildings

How does 3D concrete printing affect real life?

The advent of 3D concrete printing (3DCP) has brought about a transformative shift in the construction industry, impacting various aspects of real life. Let's discover the advantages and disadvantages of concrete printing:

Advantages

● Flexible Design: 3DCP allows for the creation of complex and intricate designs that are difficult or impossible with traditional construction methods.

● Rapid Prototyping: It accelerates the design process, enabling quick iterations and modifications.

● Print on Demand: This reduces the need for storage space and lowers inventory costs, as components can be printed as needed.

● Strong and Lightweight Parts: The structures created are robust yet lighter, which is beneficial for sectors like automotive and aerospace.

● Minimizing Waste: 3DCP uses only the material that is necessary for the part, leading to less waste.

● Cost-Effective: It can be more economical due to the reduction in labor costs and the elimination of material waste.

● Environmentally Friendly: The use of recycled materials and the reduction of waste contribute to sustainability.

Disadvantages

● Limited Materials: The selection of materials suitable for 3DCP currently needs to be exhaustive.

● Restricted Build Size: The size of print chambers can limit the scale of construction, requiring larger parts to be joined post-printing.

● Post Processing: Many parts require additional finishing, which can add to the time and cost.

● Large Volumes: When scaled up for mass production, the cost per unit does not decrease significantly.

● Part Structure: The layer-by-layer production process can lead to layers delaminating under stress.

● Reduction in Manufacturing Jobs: Automation could lead to job losses in the manufacturing sector.

● Design Inaccuracies: Some printers have lower tolerances, necessitating post-processing to meet design specifications.

Image Source: WASP

3D Printed House Cost

The cost of 3D printed houses has been a subject of interest as this technology promises to revolutionize the housing industry. Here's what you need to know about the financial aspect of 3D printed homes:

3D printed houses, created using large concrete printers, are generally more affordable than traditional homes. The cost varies based on location, design complexity, and size.

For instance, a basic one-bedroom home may start at around $10,000, with prices increasing for additional space and complexity. A four-bedroom house could be around $50,000, but more intricate designs can reach up to $500,000.

The Affordability Stems from Several Factors

Material Costs: Although the concrete used in 3D printing can be more expensive than standard construction concrete, overall material costs are often lower due to 3D printing's precision and reduced waste.

Labor Costs: Labor costs are significantly reduced as 3D printed houses require fewer workers, and the construction time is much shorter compared to traditional methods.

Sustainability: 3D-printed homes require fewer materials, which not only reduces costs but also contributes to a more sustainable construction process.

It's important to note that while the printing itself can be less expensive, other costs, such as the foundation, roofing, windows, doors, and finishes, are not typically reduced and remain comparable to those of conventional homes.

3D Concrete Printing Machines on the Market

Gantry System Printers

BetAbram P1: Originating from Slovenia, this printer has a build size of 16 x 8.2 x 2.5 meters and is known for its large-scale printing capabilities.

COBOD BOD2: It is a Danish innovation with a massive build size of 14.6 x no limit x 8.1 meters, suitable for extensive construction projects.

Total Kustom StroyBot 6.2: From the United States, this printer can construct structures within a build size of 10 x 15 x 4 meters.

Robotic Arm Printers

MAXI PRINTER: This French machine offers precision and flexibility, with a build size of 12.25 x 12.25 x 7 meters.

CyBe Construction CyBeRC 3Dp: The Netherlands offers this printer, which has a compact build size of 2.5 x 5 x 4 meters and is ideal for smaller projects.

Delta System Printers

WASP Crane WASP: This is an Italian printer with a unique modular approach. It can print within a circular area with a maximum diameter of 6.3 meters.

Prices

The cost of 3d house printing machines varies greatly, from affordable options like the BetAbram P1, which can be as low as €12,000, to more advanced systems like the COBOD BOD2, which can be a significant investment for construction companies.

Mix Design

The mix design for 3D concrete printing is crucial as it affects the printability, structural integrity, and durability of the printed structures. It typically involves a careful selection of materials, including various types of cement, aggregates, admixtures, and sometimes fibers to enhance the mechanical properties. The mix must have the right flowability for extrusion and sufficient ‘open time’ to allow for layer-by-layer construction without compromising the structural integrity.

Image Source: COBOD

What can you do with concrete printing?

1. Construction: The most prominent application of concrete printing is in the construction industry, where it’s used for building houses, office buildings, and even bridges. This method offers a faster, more cost-effective, and sustainable alternative to traditional construction methods.

2. Customized Architecture: Concrete printing allows architects to experiment with complex shapes and custom designs, pushing the boundaries of modern architecture.

3. Infrastructure Repair: It can be used for quick repairs and reinforcements of existing structures, such as filling cracks or adding layers to weakened walls.

4. Landscaping: Concrete printing can create intricate designs for landscaping purposes, including outdoor furniture, garden paths, and decorative elements.

5. Urban Furniture: Benches, fountains, and playground equipment are just a few examples of urban furniture that can be produced with concrete printing, often with unique and artistic designs.

6. Historical Preservation: For historical buildings requiring restoration, concrete printing can replicate ornate details and specific architectural elements that might be too costly or difficult to produce by hand.

7. Emergency Shelters: In disaster relief efforts, concrete printing can quickly provide durable and safe shelters for those affected.

8. Military Applications: The military has explored using concrete printing for creating strong, quick-to-assemble fortifications and other structures in conflict zones.

9. Education: Schools and universities are incorporating concrete printing into their curricula to teach students about innovative construction techniques and sustainable design.

10. Art: Artists are using concrete printing to create sculptures and installations that were not possible with traditional casting methods.

COMMENTS

- Be the first to share your thoughts!

Check out Our Special Offers

Featuring Process

- Coming Soon

Featuring Materials

- Coming Soon