Is it possible to 3D print clay?

One of the most fascinating advancements of 3D printing is the ability to print with clay. This process, which beautifully combines traditional ceramic techniques with modern technology, opens up a new world of creative possibilities for artists, designers, and engineers, sparking their imagination and curiosity.

Understanding the Process

3D printing with clay involves a method known as extrusion. Similar to how a pastry chef might decorate a cake with icing, a 3D printer extrudes clay through a nozzle, layer by layer, to build up a shape. This technique is akin to the coiling methods used in pottery for thousands of years but is controlled by precise digital instructions.

The Feasibility of Printing with Clay

Is it possible to 3D print clay? The answer is yes. With the right type of 3D printer, one designed to handle clay's unique properties, artists and creators can print objects that would be challenging or impossible to make by hand. The key is in the preparation of the clay, which must be of a specific consistency to flow through the printer without clogging and to maintain its shape as it is laid down.

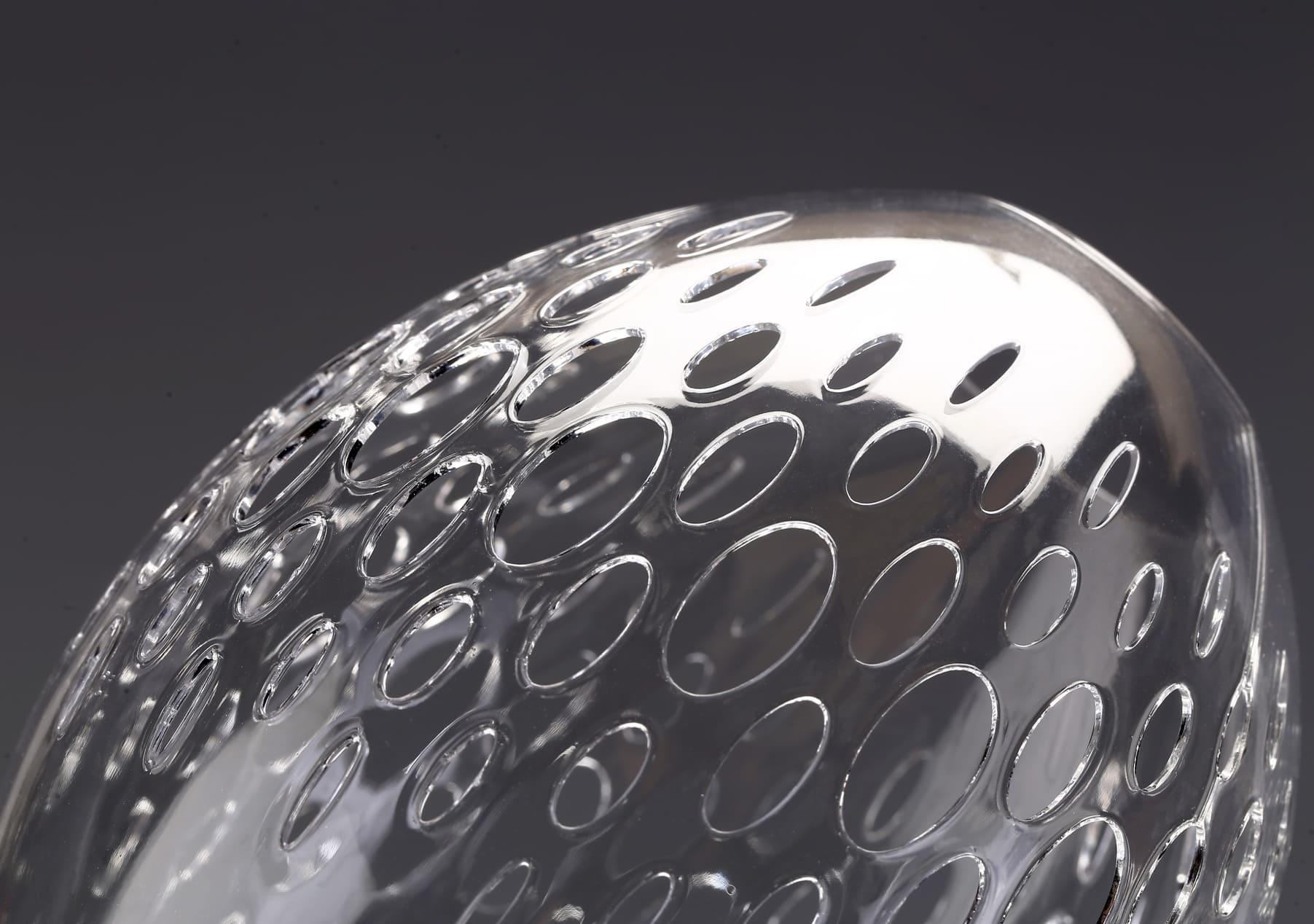

Image Source: 3D Printing Industry

Photo via James Clarke-Hicks, the University of Waterloo.

What is ceramic 3D printing?

Ceramic 3D printing is an innovative technology that allows for the creation of objects using ceramic materials in a layer-by-layer fashion. It enables the crafting of intricate and complex designs, often surpassing the capabilities of traditional ceramic-making methods.

At its core, ceramic 3D printing utilizes digital designs from computer-aided design (CAD) software to guide the printer. The printer then deposits layers of ceramic material, which can range from traditional clays to advanced technical ceramics, to build the desired shape. The object is then fired in a kiln, where it undergoes sintering – a process that fuses the ceramic particles to form a solid, durable structure.

What sets ceramic 3D printing apart is its versatility. It can be used to create everything from artistic sculptures and intricate jewelry to functional parts and components for industrial use. The technology is particularly valuable in fields that require materials with high thermal resistance, chemical stability, and biocompatibility.

Image Source: Olivier van Herpt

Ceramic 3D Printers

Ceramic 3D printers are at the forefront of combining age-old ceramics craftsmanship with the precision of modern technology. These specialized machines are designed to handle the intricacies of ceramic materials, allowing for the creation of complex and detailed objects that were once thought impossible.

Types of Ceramic 3D Printers

There are several types of ceramic 3D printers, each suited to different needs and applications.

Delta Printers

Delta printers, like the WASP Delta 2040, are known for their speed and reliability. They use a circular build platform and three arms to print objects quickly and accurately.

SLA Printers

Using stereolithography, printers such as the 3DCeram C3600 ULTIMATE employ a laser to solidify a photosensitive resin containing ceramic particles, meticulously constructing objects layer by layer with exceptional accuracy.

Binder Jetting Printers

Machines like the Desktop Metal X1 160PRO spread a layer of ceramic powder and selectively deposit a binding agent to form each layer of the object.

Choosing the Right Printer

Selecting the right ceramic 3D printer involves considering several factors.

1. Build Volume: The size of the objects you intend to print will dictate the required build volume.

2. Resolution: The level of detail needed in the final object will determine the resolution capabilities you’ll need from a printer.

3. Material Compatibility: Depending on the type of ceramics you want to work with, you’ll need a printer that can handle those specific materials.

Image Source: 3D PotterBot 10 PRO

3D Printing Ceramic Materials

Ceramic materials in 3D printing are as diverse as they are functional. They range from traditional clays to advanced technical ceramics, each offering unique properties and applications.

Traditional Ceramics: The Classics

Earthenware, stoneware, and porcelain are the classic ceramic materials that come to mind when we think of pottery and ceramics. These materials are primarily composed of natural raw materials like clay and are known for their aesthetic appeal and workability.

Technical Ceramics: The Innovators

On the other end of the spectrum are technical ceramics, also known as engineered or industrial ceramics. These include materials like Aluminum Nitride, Zirconia, Silicon Nitride, Silicon Carbide, and Alumina. Technical ceramics are favored for their superior mechanical, thermal, chemical, and electrical properties. They are often used in high-stress, high-temperature, and high-precision applications.

Why Choose Ceramic for 3D Printing?

● Aesthetic Quality: Ceramics have a unique, refined look that is highly prized in decorative and artistic applications.

● Tactility: Ceramics's tactile feel is unparalleled, making it a favorite for items meant to be held or touched.

● Chemical Resistance: Ceramics are resistant to many chemicals, making them suitable for various industrial uses.

● Biocompatibility: Certain ceramics are biocompatible, which is essential for medical implants and devices.

● Thermal Properties: Ceramics can have high or low thermal conductivity depending on the formulation.

● Electrical Insulation: Many ceramics are excellent electrical insulators, useful in electronic components.

What is 3D printed ceramics used for?

Because of their distinctive attributes, such as resistance to high temperatures, hardness, and electrical insulation, 3D-printed ceramics have gained prominence across multiple industries. The ability to 3D print ceramics has revolutionized traditional manufacturing processes, allowing for the creation of complex and sophisticated designs that were previously unattainable.

Aerospace and Automotive Industries

In the aerospace and automotive sectors, 3D-printed ceramics are used to manufacture components that benefit from the material’s lightweight and high-strength properties. These parts often include thermal shields, insulators, and other components that can withstand extreme temperatures and stresses.

Electronics and Energy

The electronics industry employs 3D-printed ceramics to fabricate components such as sensors, circuit boards, and insulators due to their outstanding electrical insulation and thermal properties. Ceramics are also used in applications such as fuel cells and batteries in the energy sector.

Medical and Dental Applications

Biocompatible ceramics are particularly advantageous in the medical field for implants and prosthetics. Dental applications also benefit from 3D-printed ceramics for creating crowns, bridges, and other dental restorations.

Art and Design

Artists and designers use 3D-printed ceramics to push the boundaries of creativity, producing intricate sculptures and functional art pieces that are both aesthetically pleasing and tactile.

Research and Development

In R&D, 3D-printed ceramics are used to quickly and cost-effectively prototype and test new designs, enabling rapid innovation and development.

Environmental and Sustainability

Ceramic 3D printing aids sustainability initiatives by minimizing material waste and facilitating the fabrication of parts nearer to their final destination, thereby lowering transportation-related emissions.

COMMENTS

- Be the first to share your thoughts!