3D Printing Car Parts Open New Possibilities

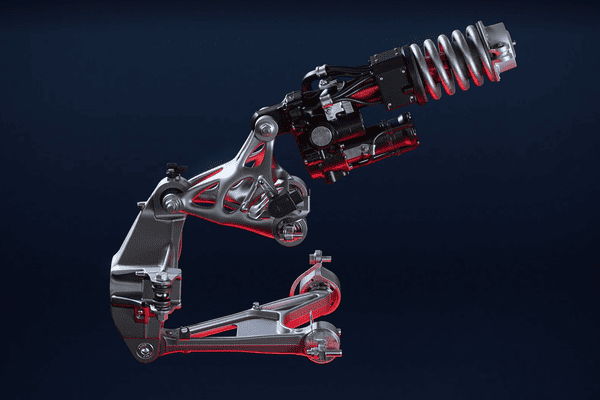

With AM technology, designers and engineers are no longer constrained by the limitations of traditional manufacturing methods. They can now explore innovative designs that were previously impossible or too costly to produce. From intricate engine components to sleek, aerodynamic body parts, 3D printing enables the creation of unique and tailored pieces that enhance performance and aesthetic appeal.

The flexibility of 3D printing materials also plays a crucial role in this revolution. High-performance polymers, advanced composites, and even metals can be 3D printed, providing the durability and resilience required for automotive applications.

Moreover, 3D printing car parts on demand reduces inventory costs and waste, as parts are produced only when needed, which aligns with the industry’s move towards sustainability and eco-friendly practices.

3D printing empowers manufacturers to push the boundaries of car design, leading to advancements that will shape the future of the automotive industry.

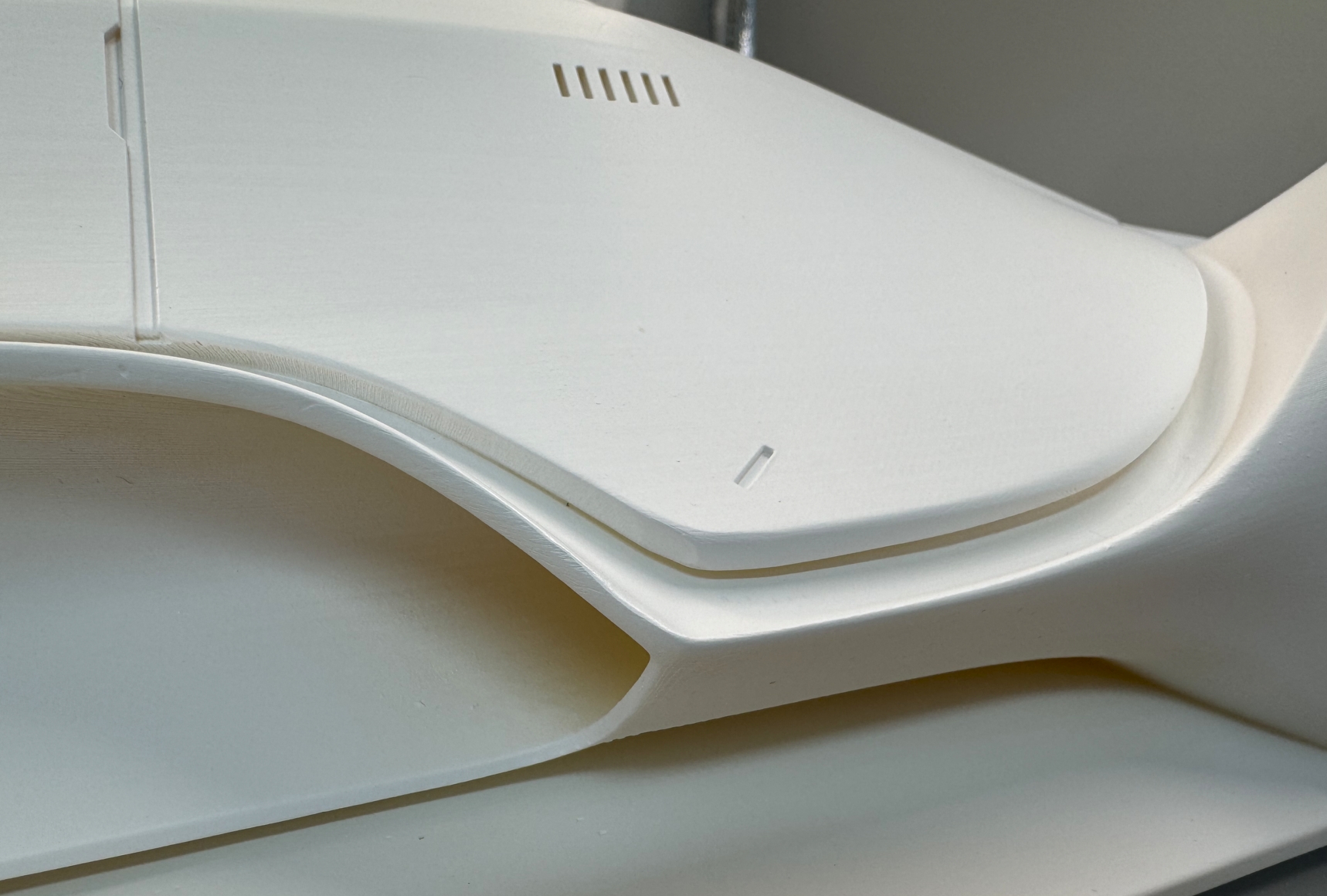

Image Source: Bugatti

3D Printing Car Applications

3D printing production powerhouse for car accessories and spare parts. The technology’s precision and versatility allow for the creation of a wide range of automotive components:

● Custom Vents and Caps: Personalize your vehicle with custom-designed vents and caps that match your style.

● Functional Pistons: Pistons are at the heart of your car’s engine, and 3D printing them can lead to improved performance and efficiency.

● Dashboard Accessories: From smartphone holders to decorative elements, 3D printing allows you to customize your dashboard to your needs and tastes.

● Replacement Knobs and Switches: Whether you’re restoring a classic car or updating your vehicle’s interior, 3D-printed knobs and switches are a perfect fit.

● Door Handles and Hinges: These frequently used parts can wear out over time, but 3D printing offers a quick and precise replacement solution.

● Custom Light Covers: Create unique light covers that enhance the aesthetic appeal of your car while ensuring safety on the road.

● Prototypes for Testing: Before mass production, 3D printing allows for the creation of prototypes for aerodynamic testing and design verification.

3D Printed Car Parts Examples

1. Bugatti Bolide

The Bugatti Bolide is a remarkable example of how 3D printing technology is being utilized to push the boundaries of automotive design and performance. The Bolide, which is an experimental track-oriented hypersports car, features 3D-printed parts made from titanium. These parts include all the screw and fastening elements, as well as hollow, thin-walled functional components made from an aerospace titanium alloy. The use of 3D printed titanium parts has contributed to the Bolide’s impressive weight-to-power ratio.

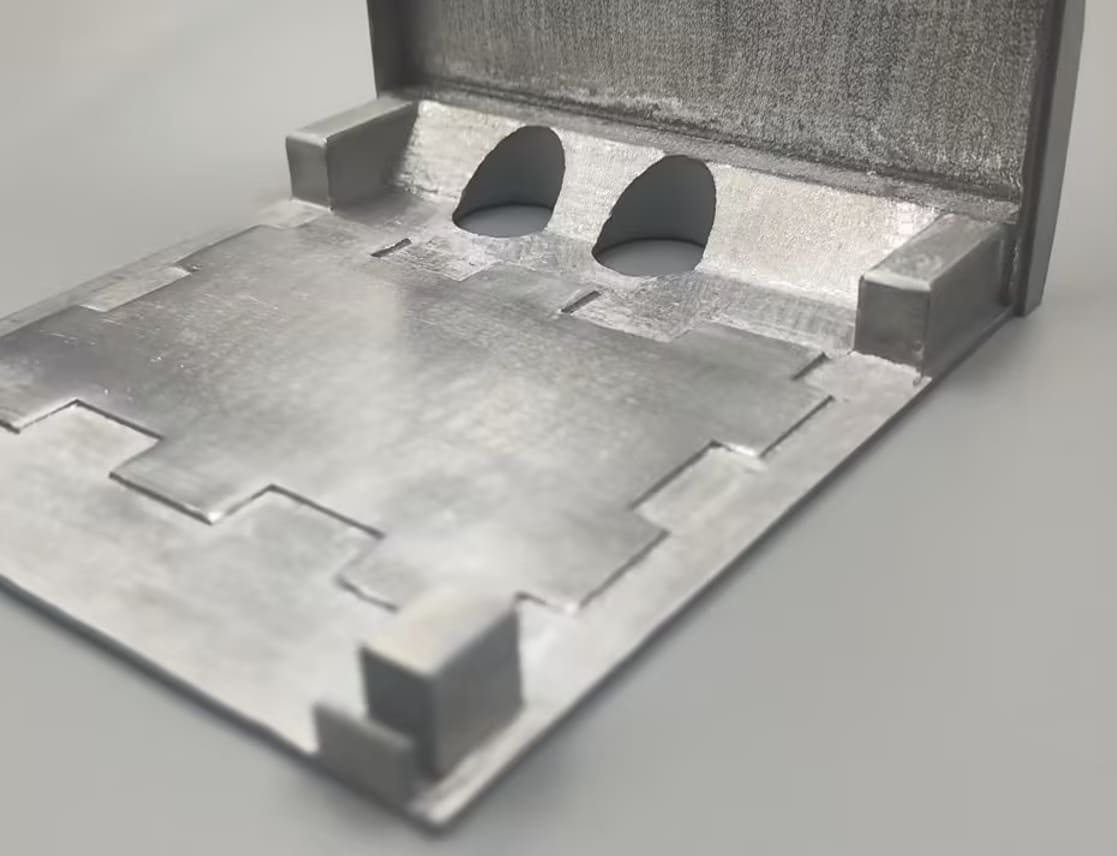

Image Source: VoxelMatters

2. 2024 Cadillac Celestiq

The 2024 Cadillac Celestiq is distinguished by its use of more than 115 3D printed parts, which is more than any other production car to date. These components range from decorative elements like the steering wheel trim and console decor to structural and safety-critical parts such as seat belt guide loops and certain underbody components. The Celestiq’s extensive use of 3D printing showcases the technology’s ability to enhance customization, allowing for personalized touches like embossed names on the steering wheel.

Image Source: Cadillac

3. Ford

At the North American International Auto Show (NAIAS) 2019, Carbon and Ford showcased a series of 3D printed end-use parts, marking a significant step forward in their collaboration. The showcased parts included the Ford Focus HVAC (Heating, Ventilation, and Cooling) Lever Arm Service Parts, Ford F-150 Raptor Auxiliary Plugs, and Ford Mustang GT500 Electric Parking Brake Brackets.

These components were produced using Carbon’s Digital Light Synthesis technology and EPX 82 material, known for its high-strength and high-resolution properties. The material was chosen for its ability to meet Ford’s stringent performance standards, which include requirements for interior weathering, heat exposures, UV stability, fluid and chemical resistance, flammability, and fogging.

Image Source: VoxelMatters

4. BMW

The BMW Group is advancing the use of industrial-scale 3D printing within its production systems. The goal is to elevate additive manufacturing to industrial levels and integrate it systematically into vehicle development and production for economic benefits. This strategic move allows BMW to fully leverage the advantages of 3D printing, such as rapid component availability, flexible design, and the elimination of elaborate tooling for part manufacturing.

Since mid-2020, BMW has been using 3D printing to produce both metal and polymer parts for Rolls-Royce Motor Cars. These parts are used throughout the vehicle, including the body and passenger cell, and are known for their functionality and rigidity. The process was developed at BMW’s own Additive Manufacturing Campus, which also produces polymer parts through multi-jet fusion and selective laser sintering.

At BMW Group Plant Landshut, metal parts are created using laser beam melting, and these 3D printed components are integrated into car bodies in an almost entirely automated process. The company also utilizes generative design in component development and employs artificial intelligence to screen components for additive manufacturability.

Image Source: BMW

STL Files for 3D Printing Car Parts

1. Printables

Printables provides access to a wide array of designs that cater to various needs and preferences. The platform’s user-friendly interface allows for easy navigation and discovery of car part designs, ranging from functional engine components to stylish accessories. Each file is meticulously crafted to ensure compatibility with a variety of 3D printers.

Image Source: Printables

2. Thingiverse

Thingiverse hosts an extensive collection of STL files for car parts, offering a rich resource for individuals looking to print everything from functional components to decorative enhancements for their vehicles. The repository boasts a variety of designs that cater to different aspects of car modification and repair. Each STL file on Thingiverse is accompanied by detailed descriptions and user-generated feedback, providing insights into print quality and design functionality.

Image Source: Thingiverse

3. Cults3D

Cults stands out as a digital haven for 3D printing enthusiasts, offering an impressive array of STL files for automotive parts that cater to both practical needs and creative aspirations. This platform is a hub for innovation and customization, providing 3D model files with access to a vast selection of files for printing replacement parts, enhancements, and even novel accessories for vehicles.

Image Source: Cults3D

4. Yeggi

Yeggi, a comprehensive search engine for 3D printable models, offers an extensive selection of STL files for auto parts. This platform aggregates a vast array of STL files from various sources, providing users with access to a multitude of designs for both functional and aesthetic car components. The platform’s user-friendly search functionality makes it easy to find the perfect design. Each design is ready for download and printing, allowing for immediate implementation into your automotive project.

Image Source: yeggi

CAD Software for Designing

1. Catia

Catia, developed by Dassault Systèmes, is a robust multi-platform suite that supports various stages of product development, including conceptualization, design, engineering, and manufacturing. It’s a comprehensive software for the automotive industry.

2. AutoCAD

AutoCAD, developed by Autodesk, is a powerhouse in the world of computer-aided design (CAD) software. It’s widely recognized for its robust set of tools that cater to a variety of design needs.

3. SolidWorks

SolidWorks is a premier 3D CAD software that offers a suite of tools for product design, engineering, and manufacturing. Known for its user-friendly interface and powerful features, SOLIDWORKS is widely used across the automotive industry.

4. Creo Parametric

Creo Parametric is a cutting-edge 3D CAD software provided by PTC that offers a comprehensive suite of tools for product design and development. It’s designed to meet the demands of manufacturing companies facing complex engineering challenges.

3D Printed Car Spare Parts Producers

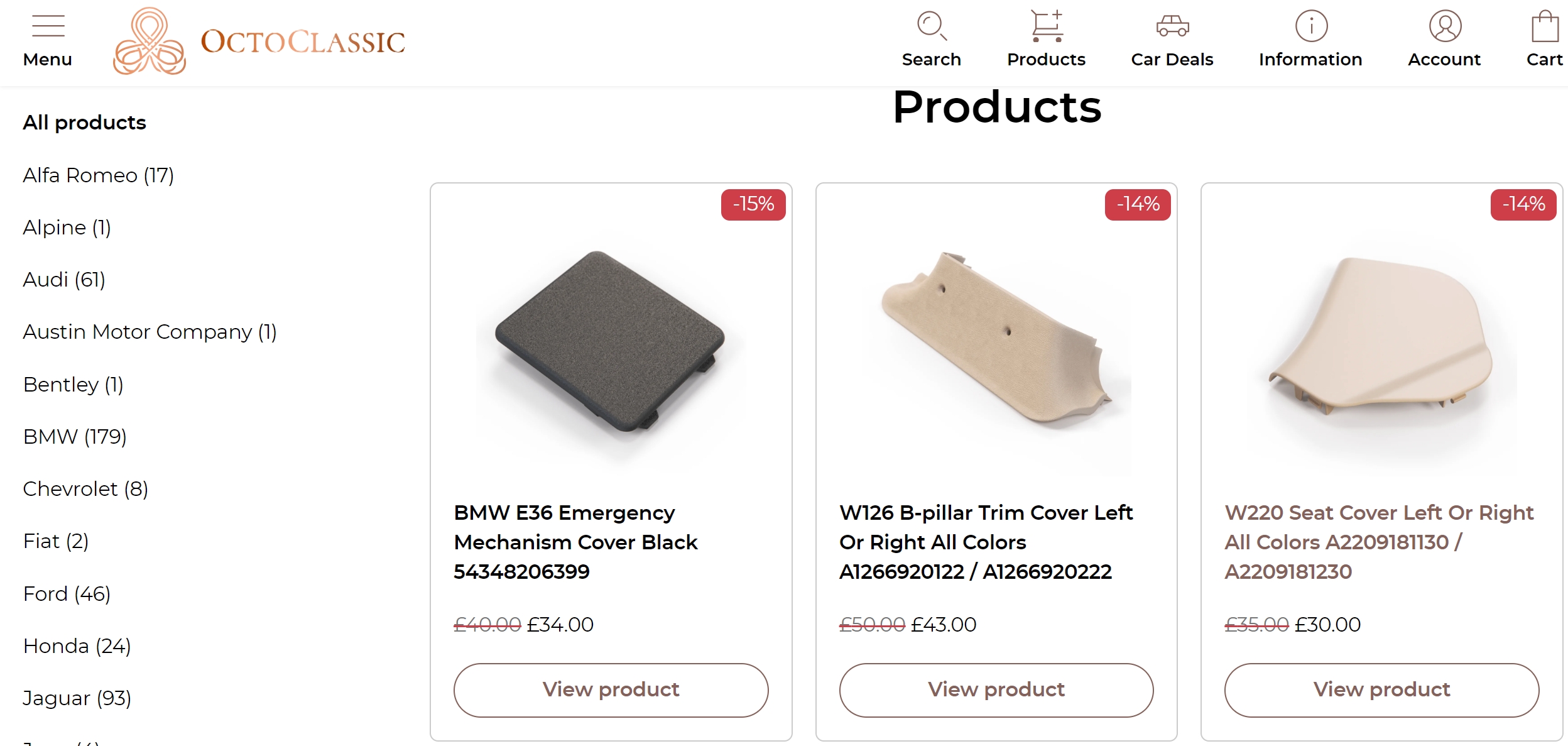

1. OctoClassic

OctoClassic is at the forefront of the 3D-printed car spare parts industry, offering an innovative solution for classic car enthusiasts and restorers. Their approach to using 3D printing technology ensures that even the most elusive car parts are accessible, providing a lifeline for vehicles that would otherwise be left incomplete due to the scarcity of original parts.

OctoClassic boasts a wide array of products, from front bumpers for luxury cars like the Rolls Royce Phantom to practical components such as BMW cup holders and battery spacers. They use high-quality materials suitable for 3D printing technology, ensuring durability and fit for each part. OctoClassic offers customization options, allowing car owners to have parts tailored to their specific needs.

Image Source: OctoClassic

2. iPrint3DSpares

i-Print3DSpares is a pioneering e-commerce marketplace for automotive spare parts. Their innovative approach involves selling digital design files for car parts under license rather than physical parts. This model allows for on-demand, on-site printing of parts, significantly reducing the need for vehicle dealerships, fleets, and service centers to order parts from off-site locations.

They offer a wide range of car parts digital design files, tested and certified for on-demand 3D printing. This system enables the local production of spare parts, reducing costs associated with stockpiles at centralized distribution centers.

Image Source: iPrint3DSpares

3D Printing Car Parts Services at 3DSPRO

3DSPRO is helping the automotive industry with our comprehensive 3D printing services, tailored to meet the intricate demands of car part production:

Selective Laser Sintering: 3DSPRO utilizes SLS to create strong and durable parts with complex geometries, making it ideal for both prototyping and end-use components.

Multi Jet Fusion: With MJF, 3DSPRO offers high precision and speed, producing functional parts with excellent mechanical properties and fine detail.

Selective Laser Melting: 3DSPRO’s metal 3D printing services enable the creation of lightweight and high-strength metal parts, using materials like titanium and aluminum, which are essential for critical automotive applications.

We are a one-stop-shop for automotive companies looking to innovate and streamline their manufacturing processes. Our capabilities to print on-demand reduces inventory costs and waste, while also allowing for rapid prototyping, customization, and post-processing. Try our AI-powered quoting system and check what we can offer! Price match available.

3DSPRO Detailed Car Part (Spray-painted)

COMMENTS

- Be the first to share your thoughts!