Real-World Examples of 3D Printing in Apple Watch

1. Apple Watch Series 9 and Ultra

Apple has been actively incorporating 3D printing technology in the production of its Apple Watch Series 9 and the second-generation Apple Watch Ultra. Specifically, Apple is using a technique called “binder jetting” to create the chassis for some models. Binder jetting involves printing the device’s outline using a powdered substance, which is then solidified through heat and pressure to form a material.

Image Source: Apple

2. Titanium Components

In addition to the chassis, Apple is also using 3D printing for certain titanium components in the Apple Watch Ultra. Metal 3D printing allows for more intricate designs and improved material efficiency. The use of 3D printing for these parts is expected to expand to other Apple devices in the future, showcasing the company’s commitment to innovative manufacturing techniques.

3. Apple Watch Bands and Accessories

3D printing is also being used for rapid prototyping and customization of Apple Watch bands and accessories, allowing Apple to quickly iterate designs and offer personalized options to consumers.

Source from MacRumors and 3D Printing Industry

Why Apple is trying to use 3D printing to make its products?

Enhanced Production Efficiency

Apple is leveraging 3D printing to streamline its manufacturing processes. Traditional manufacturing methods, such as CNC machining, involve cutting away material from a solid block, which can be time-consuming and wasteful. In contrast, 3D printing is an additive process, building components layer by layer, which significantly reduces material waste and production time.

Cost Reduction

By adopting 3D printing, Apple aims to lower production costs. The additive manufacturing process uses only the necessary amount of material, minimizing waste and reducing the cost of raw materials. Additionally, 3D printing can consolidate multiple parts into a single component, reducing assembly costs and simplifying the supply chain. These cost savings can be particularly significant when producing high-precision components like those used in the Apple Watch.

Material Innovation

Apple is exploring the use of advanced materials, such as titanium, in its products. 3D printing allows for the efficient use of these materials, enabling the creation of intricate designs. This capability enhances the durability and performance of Apple devices and opens up new possibilities for innovative product designs.

Customization and Flexibility

3D printing provides great flexibility in design and customization. Apple can quickly prototype and iterate new designs, allowing it to quickly innovate and adapt to market needs, such as customizing Apple Watch bands to enhance user experience and meet diverse consumer preferences.

Environmental Sustainability

Sustainability is a key focus for Apple, and 3D printing aligns with the company’s environmental goals. The additive manufacturing process generates less waste compared to traditional subtractive methods, reducing the environmental impact of production. Additionally, 3D printing can utilize recycled materials.

Image Source: Apple

3DSPRO is Ready to Empower the High-Tech Industry

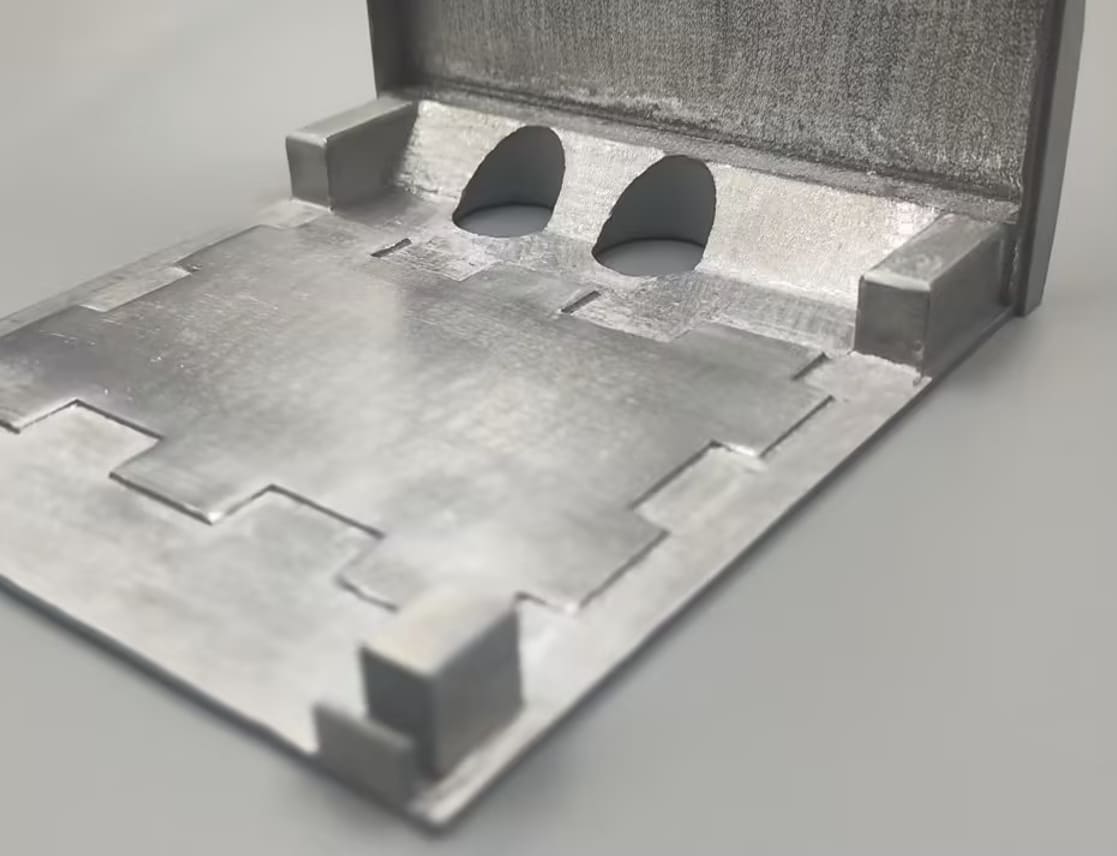

3D Printed Watch Parts at 3DSPRO

Our 3D Printing Services

3DSPRO offers a wide range of 3D printing services designed to meet the diverse needs of the high-tech industry. These technologies allow us to cater to a wide range of applications, from rapid prototyping to low-volume production, ensuring our customers receive the best solution for their projects.

Selective Laser Melting (SLM)

Fuses metal powders such as aluminum, titanium, and stainless steel to produce high-strength metal parts with intricate designs.

Selective Laser Sintering (SLS)

Utilizes powdered materials like nylon, polycarbonate, and TPU to create strong, durable parts with complex geometries.

Multi Jet Fusion (MJF)

A high-speed, high-precision technology that produces functional parts with excellent mechanical properties using polyamide materials.

Stereolithography (SLA)

Uses light-curing resin to create precise and detailed objects with a smooth surface finish.

Digital Light Processing (DLP)

Ideal for producing highly detailed and accurate parts with a smooth surface finish using liquid photopolymer resins.

Our 3D Plus™ Solutions

Our 3D Plus™ solutions are designed to empower the high-tech industry by integrating advanced 3D printing capabilities with comprehensive support throughout the product development lifecycle.

Comprehensive Surface Finishing Options

We offer more than 20 types of post-processing options, such as spray painting, dyeing, anodizing, electroplating, electrocoating, powder coating, vapor smoothing, tumbling, polishing, bead blasting, and more!

Customization

Tailored solutions to meet specific project requirements, ensuring that every detail is accounted for.

Material Expertise

Access to a wide range of materials, including advanced polymers and metals, to match the unique needs of each project.

End-to-End Support

From initial design and prototyping to final production, our team provides expert guidance and support at every stage.

Quality Assurance

Rigorous quality control processes to ensure that all parts meet the highest standards of precision and durability.

Empowering Innovation

At 3DSPRO, we are committed to driving innovation in the high-tech industry. Our advanced 3D Printing Services and 3D Plus™ Solutions enable companies to accelerate product development, improve product performance, reduce costs and increase sustainability. Here is our instant quote system, Squote, which integrates all 3D Printing Services and 3D Plus™ Solutions on one platform. Try it now:

COMMENTS

- Be the first to share your thoughts!