Cost and Budget Planning for 3D Printing Project

As we approach 2025, strategic cost and budget planning for 3D printing projects becomes more important than ever. We will guide you through the essential aspects of cost and budget planning for 3D printing projects.

Initial Investment in Equipment

Investing in a high-quality 3D printer and related equipment is one of the foundations for a successful 3D printing project. While initial costs may be high, choosing a reliable and advanced machine can lead to long-term savings through increased efficiency, reduced maintenance, and improved output quality. Consider the specific needs of your project, such as the required build volume, material compatibility, and desired precision, to select the most appropriate equipment.

Material Cost and Selection

Different materials, such as metals, polymers, and composites, have different price points and properties. It is critical to budget for the material that best meets your project requirements while also considering factors such as durability, strength, and surface finish. Additionally, staying abreast of new material developments can result in cost savings and improved performance.

Operating Costs and Maintenance

Operating costs, including energy consumption, labor, and maintenance, should be carefully planned and monitored. Regular maintenance of your 3D printing equipment is essential to prevent unexpected failures and ensure consistent performance. Implementing a proactive maintenance plan can help you avoid costly repairs and downtime.

Financial Planning and ROI Analysis

Conducting a thorough cost-benefit analysis is essential to understanding the return on investment (ROI) of a 3D printing project. It involves evaluating the potential savings of reduced material waste, shorter production times, and improved product quality relative to initial and ongoing costs.

Sustainability and Environmental Considerations

Utilizing eco-friendly materials and adopting sustainable practices can reduce waste and attract environmentally conscious customers. Emphasizing the reduced environmental impact of 3D printing compared to traditional manufacturing methods can also enhance your brand reputation and attract new business opportunities.

Things to Be Done for the 2025 Projects

1. Set Clear Goals and Plans

● Define Project Scope: Clearly outline the scope of the project, including specific deliverables, timelines, and milestones. It helps you stay focused and effectively measure progress.

● Identify Key Performance Indicators (KPIs): Establish KPIs to track the success of the project, including metrics such as production speed, material efficiency, and cost savings.

2. Invest in Training and Skills Development

● Upskill Your Team: Make sure your team is well-versed in the latest 3D printing technologies and techniques. Consider offering training programs or workshops to upgrade their skills.

● Stay Updated: Encourage continuous learning by keeping up with industry trends, attending conferences, and participating in online courses.

3. Optimize Workflows

● Streamline Processes: Identify and eliminate bottlenecks in workflows to improve efficiency. Implementing automation wherever possible can save time and reduce errors.

● Collaboration Tools: Leverage project management and collaboration tools to enhance communication and coordination among team members.

4. Focus on Quality Control

● Implement Quality Checks: Establish a strict quality control process to ensure that your 3D printed products meet the required standards. Regular inspections and testing can help detect problems early.

● Feedback Loops: Establish feedback loops with your customers to gather insights and continuously improve your products and services.

5. Explore New Materials and Technologies

● Material Innovation: Stay up to date on new materials that can enhance the performance and aesthetics of your 3D printed products. Experimenting with advanced composites, biocompatible materials, and eco-friendly options can open up new possibilities.

● Adopt Emerging Technologies: Keep an eye on emerging technologies, such as AI-driven design tools, multi-material printing, and hybrid manufacturing techniques. Integrating these innovations can give you a competitive advantage.

6. Strengthen Supplier Relationships

● Reliable Suppliers: Build strong relationships with reliable suppliers to ensure a steady supply of high-quality materials and components. It helps prevent delays and maintain project consistency.

● Negotiations and Contracts: Negotiate favorable terms and contracts with suppliers to ensure better pricing and delivery schedules.

7. Plan for Scalability

● Scalable Solutions: Design your project with scalability in mind. Consider how you can expand your production capacity and accommodate growing demand without compromising quality.

● Flexible Infrastructure: Invest in flexible infrastructure that can accommodate future growth, such as modular workspaces and scalable software solutions.

8. Financial Planning and Risk Management

● Budget Allocation: Allocate your budget wisely, prioritizing key areas such as equipment, materials, and training. Set aside emergency funds to cover unexpected expenses.

● Risk Mitigation: Identify potential risks and develop mitigation strategies, including diversifying suppliers, securing backup equipment, and developing a strong disaster recovery plan.

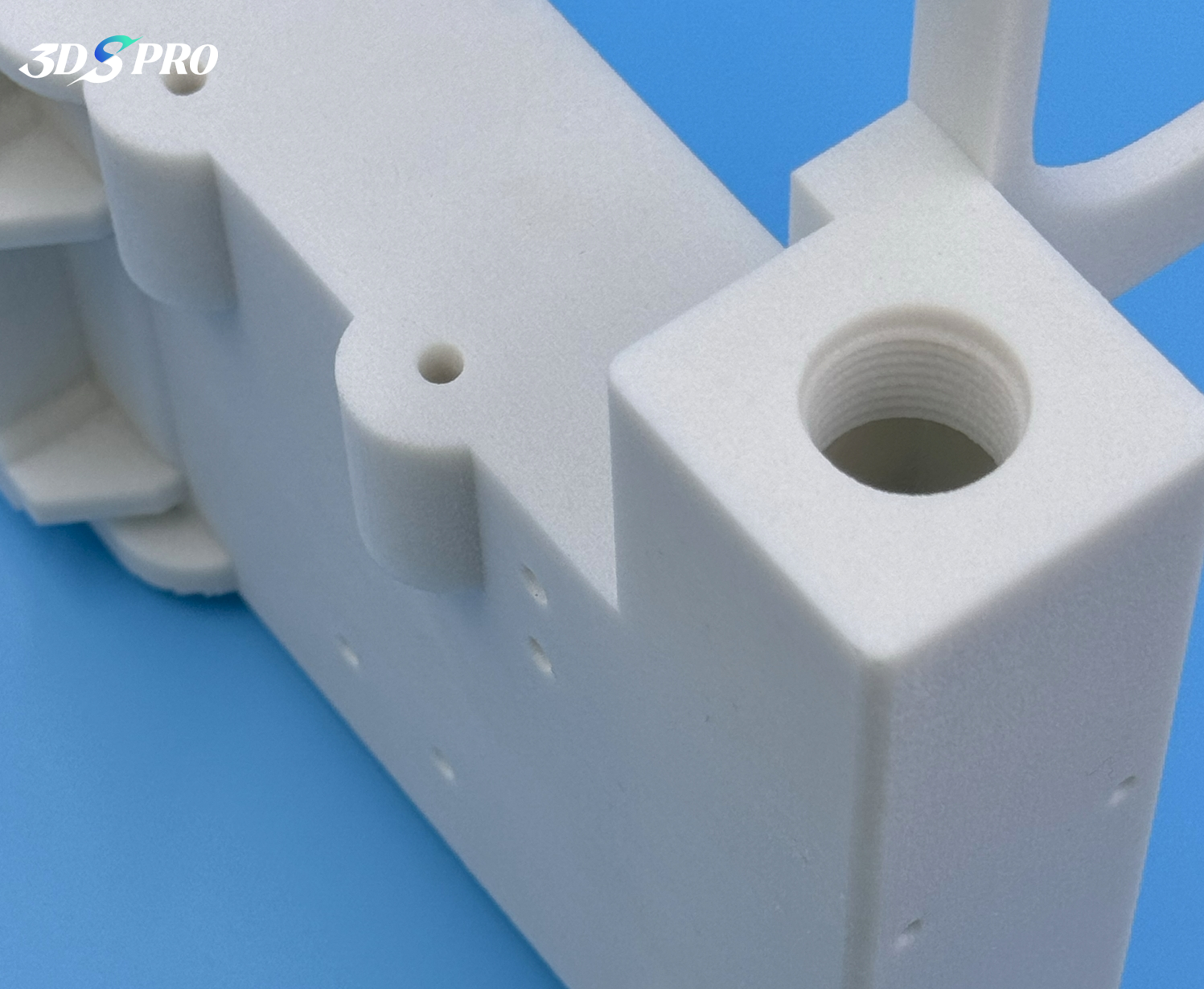

A SLS 3D Printed Nylon Functional Prototype Project at 3DSPRO

Understanding the Market Trends and Take Actions

Understanding market trends is essential to staying competitive in the 3D printing industry.

Regularly monitoring industry reports, attending conferences, and engaging with experts can provide valuable insights into technological advancements and emerging opportunities.

Attending trade shows and networking events allows you to connect with industry leaders and discover new innovations.

Additionally, analyzing market data and customer feedback can help identify shifts in demand and preferences, guiding your strategic decisions.

Investing in research and development (R&D) is essential to staying ahead of the curve, allowing you to explore new materials and applications.

Collaborating with research institutions and industry partners can further enhance your ability to innovate. By staying informed and proactive, you can take advantage of market trends to optimize your 3D printing projects and maintain a competitive edge in 2025.

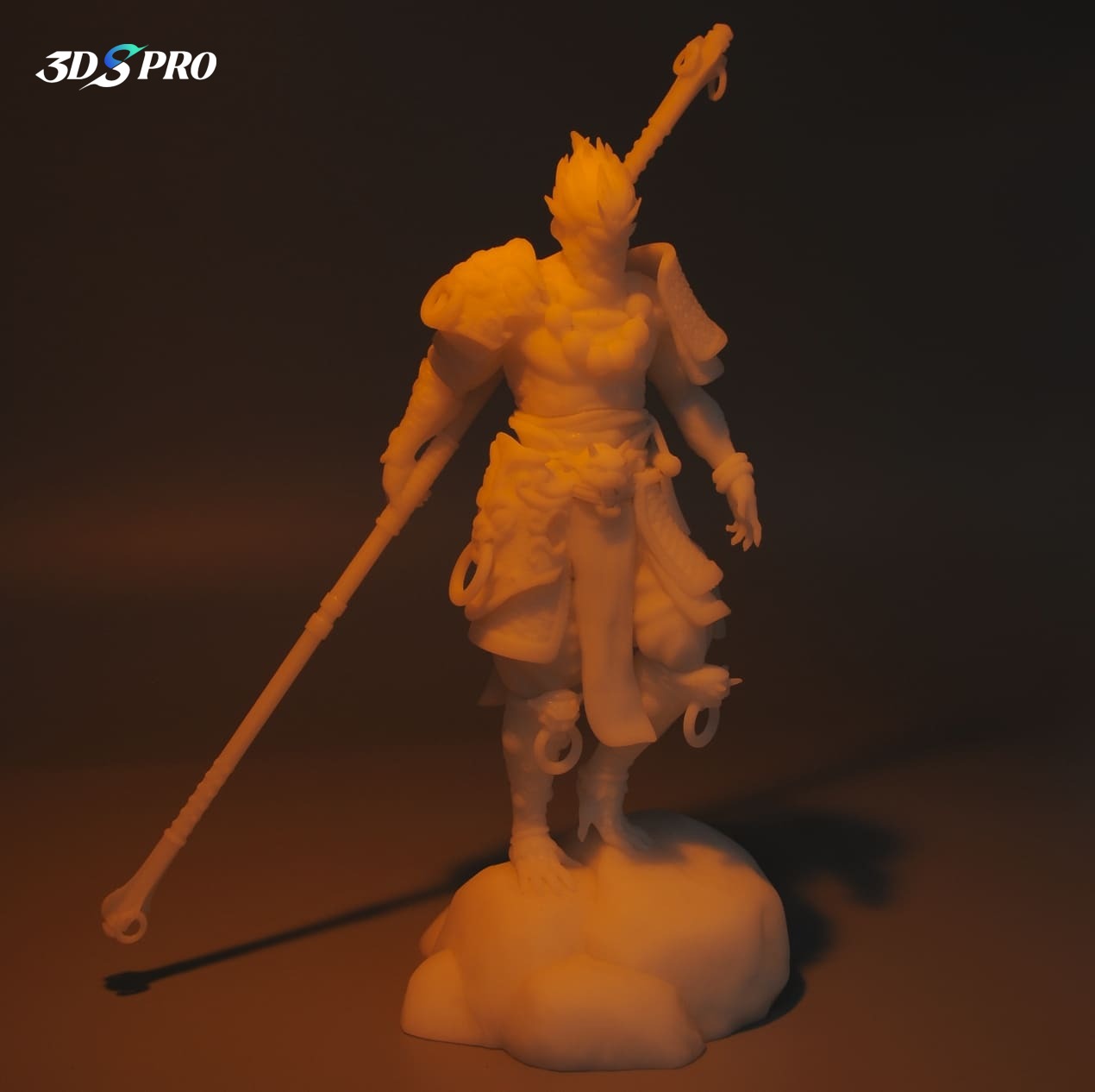

Black Myth Wukong Resin 3D Print Project at 3DSPRO

Our 3D Printing Services are Ready for You

At 3DSPRO, we offer a comprehensive range of 3D printing services to meet the needs of any 3D printing project. Whether you are a startup looking to prototype a new product, a manufacturer seeking to optimize production, or an artist aiming to bring your creative vision to life, we have the expertise and technology to support your project.

We have stereolithography and digital light processing for resin 3D printing, selective laser sintering and multi-jet fusion for nylon and plastic 3D printing, and selective laser melting for metal 3D printing. We offer a wide range of materials, from durable metals like aluminum and stainless steel to versatile polymers like nylon and TPU, allowing you to choose the best option for your specific application.

In addition to printing, our services include post-processing techniques such as painting, dyeing, anodizing, plating, powder coating, screen printing, polishing, sandblasting, vapor smoothing, tumbling, and more! Our experienced team of engineers and designers works closely with you to ensure that every detail of your project is executed perfectly.

Create your 2025 plan with 3DSPRO and get your plan costs.

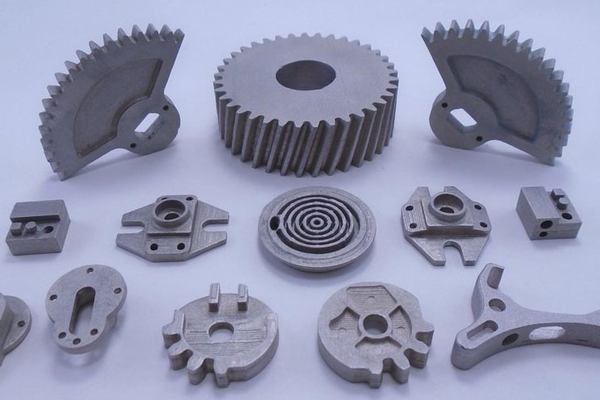

A Metal 3D Printed Boot Project at 3DSPRO

COMMENTS

- Be the first to share your thoughts!