The Hidden Cost of Waiting

Traditional spare parts management is a lose-lose proposition. Stock too many parts, and you're bleeding capital through inventory carrying costs. Stock too few, and a single component failure can idle million-dollar production lines for weeks.

Consider the cascade effect: When a specialized bracket fails on your packaging line, you're not just paying for the replacement part.

You're paying for:

• Lost production capacity ($50,000-500,000 per day)

• Expedited shipping (often 10x standard rates)

• Overtime labor to catch up on delayed orders

• Potential contract penalties for late deliveries

• Customer relationship damage that's impossible to quantify

The real killer? Lead times. Custom mechanical components from traditional suppliers average 4-8 weeks. For obsolete parts where tooling no longer exists, you might wait 3-6 months if you can source them at all.

Meanwhile, your competitors are eliminating these vulnerabilities entirely.

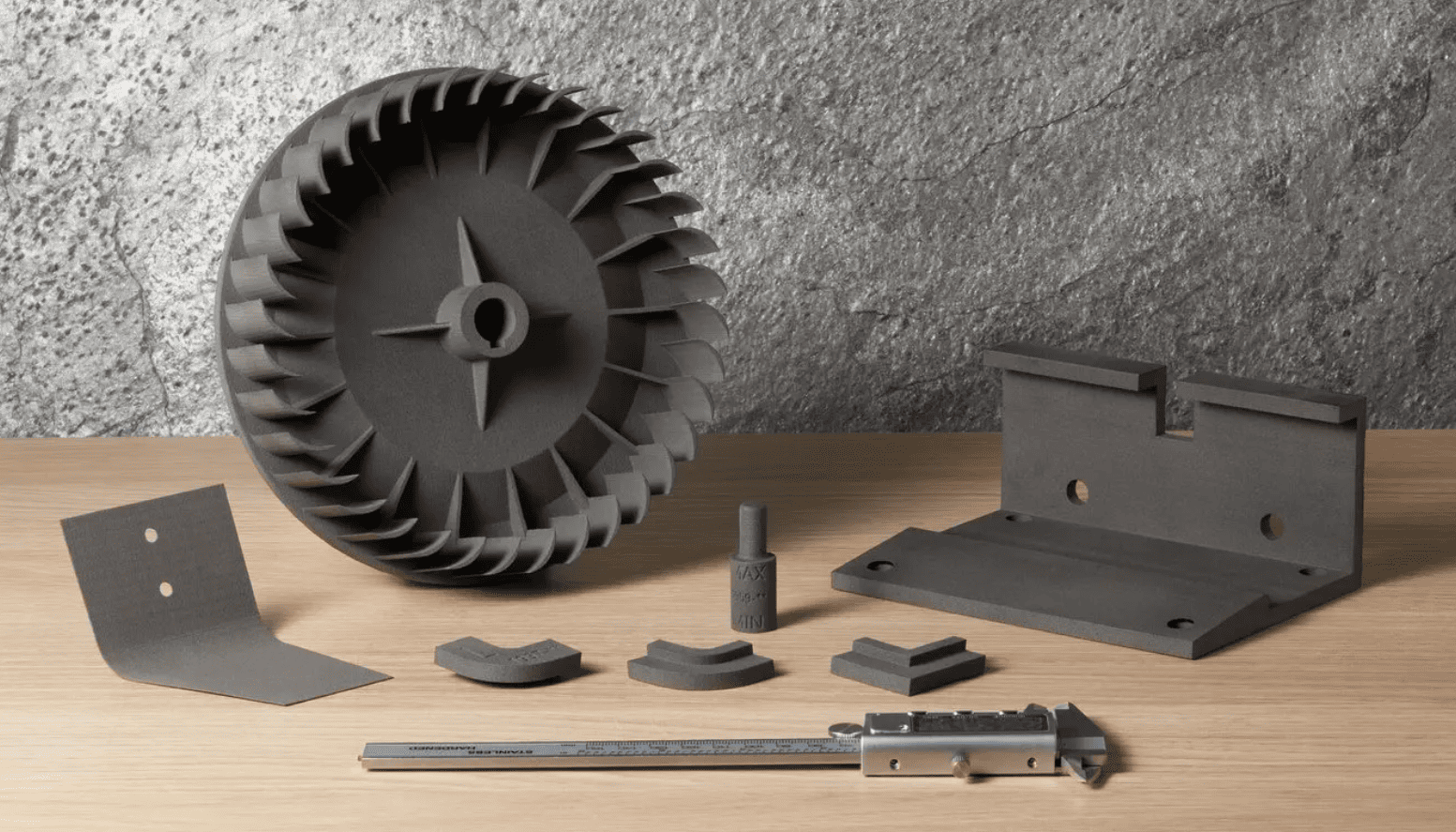

3D Printing: Print Parts in Hours, Not Weeks

3D printing has reached an inflection point. Industrial 3D printing delivers production-ready parts in engineering-grade materials, not prototypes, but functional components that meet or exceed original specifications.

Here's what changes when you shift to on-demand production:

• Speed: Complex geometries that take weeks to machine can be printed in 8-48 hours. No tooling setup, no minimum order quantities, no waiting for shop floor availability.

• Flexibility: Digital inventory means infinite shelf life. Store part files, not physical parts. Update designs instantly based on field performance. Consolidate assemblies into single, stronger components.

• Cost predictability: Eliminate emergency shipping, reduce warehouse footprint by 40-70%, and convert fixed inventory costs to variable production costs. Pay only for what you use, when you use it.

• Material options: Today's industrial 3D printers work with materials that match traditional manufacturing, from chemical-resistant thermoplastics to high-temperature PEEK, carbon fiber composites to metal alloys. If your current part is injection molded ABS, printed ABS delivers identical properties.

Image Source: Formlabs

Industry-Specific Applications

Different sectors are discovering unique advantages in on-demand spare parts production:

Manufacturing & Automation

• Custom gripper jaws and end effectors printed overnight

• Obsolete PLC housings for 20-year-old equipment

• Wear plates and guides in abrasion-resistant materials

Aerospace & Defense

• Flight-certified brackets and ducting components

• Ground support equipment parts with zero lead time

• Legacy aircraft components no longer in production

• Deployment-ready parts printed at forward operating bases

Medical Equipment

• Custom mounting brackets for diagnostic equipment

• Sterilizable components for surgical tools

• Patient-specific fixtures and guides

Energy & Utilities

• Valve components resistant to specific chemicals

• Turbine blade fixtures for maintenance operations

• Insulating housings for high-voltage equipment

• Weather-resistant outdoor enclosures

Your 30-Day Roadmap to On-Demand Spare Parts

Days 1-7: Identify High-Impact Targets

• Audit your emergency purchase orders from the last 12 months

• List parts with lead times over 2 weeks

• Calculate true downtime costs for each component

• Identify your top 10 "problem parts", such as high cost, long lead time, or frequent failure

Days 8-14: Validate Technical Feasibility

• Gather 3D files or create them from existing parts

• Confirm material requirements and environmental conditions

• Get quotes for both traditional and 3D printed versions

• Run cost comparisons, including inventory carrying costs

Days 15-21: Pilot Program Launch

• Select 2-3 parts for initial production

• Order test parts in required materials

• Conduct fit, form, and function testing

• Document performance versus original components

Days 22-30: Scale and Systematize

• Create digital inventory for validated parts

• Establish reorder triggers and approval workflows

• Train maintenance teams on the new procurement process

• Calculate and communicate achieved savings

3DSPRO: Your Fast-Track to Zero-Inventory Spare Parts

While building internal 3D printing capabilities makes sense for some organizations, partnering with specialized service providers accelerates results and eliminates capital investment.

3DSPRO brings 10+ years of industrial additive manufacturing expertise to your spare parts challenge:

Instant Production Capacity

• 100+ industrial-grade 3D printers across multiple technologies (SLM, SLS, MJF, SLA, LCD, DLP)

• No equipment investment or maintenance burden on your team

• Surge capacity for urgent needs, print 100 parts as easily as one

Engineering-Grade Materials

• 100+ certified materials, from basic polymers and advanced composites to metal alloys

• Chemical resistance, UV stability, high-temperature performance, matched to your application

• Material property data sheets and compliance certifications for every part

Speed at Scale

• 24-72 hours turnaround for most geometries

• Automated quoting in under 60 seconds

• Direct integration with your procurement systems

• Global shipping from strategically located production centers

Quality Assurance Built In

• ISO 9001:2015 certified processes

• Dimensional inspection for critical features

• Full traceability from file to finished part

• Storage of your validated part files in the User Center's 3D Model Space

Ready to slash downtime and inventory costs?

Upload your part files for an instant quote. Our engineering team reviews every file to optimize for 3D printing, often reducing costs and improving performance. No minimum orders, no setup fees, no long-term commitments.

COMMENTS

- Be the first to share your thoughts!