Partner Profile: BizLink Healthcare

BizLink Healthcare is a global innovator in the medical device industry, specializing in cable systems and robotic solutions that power healthcare technologies.

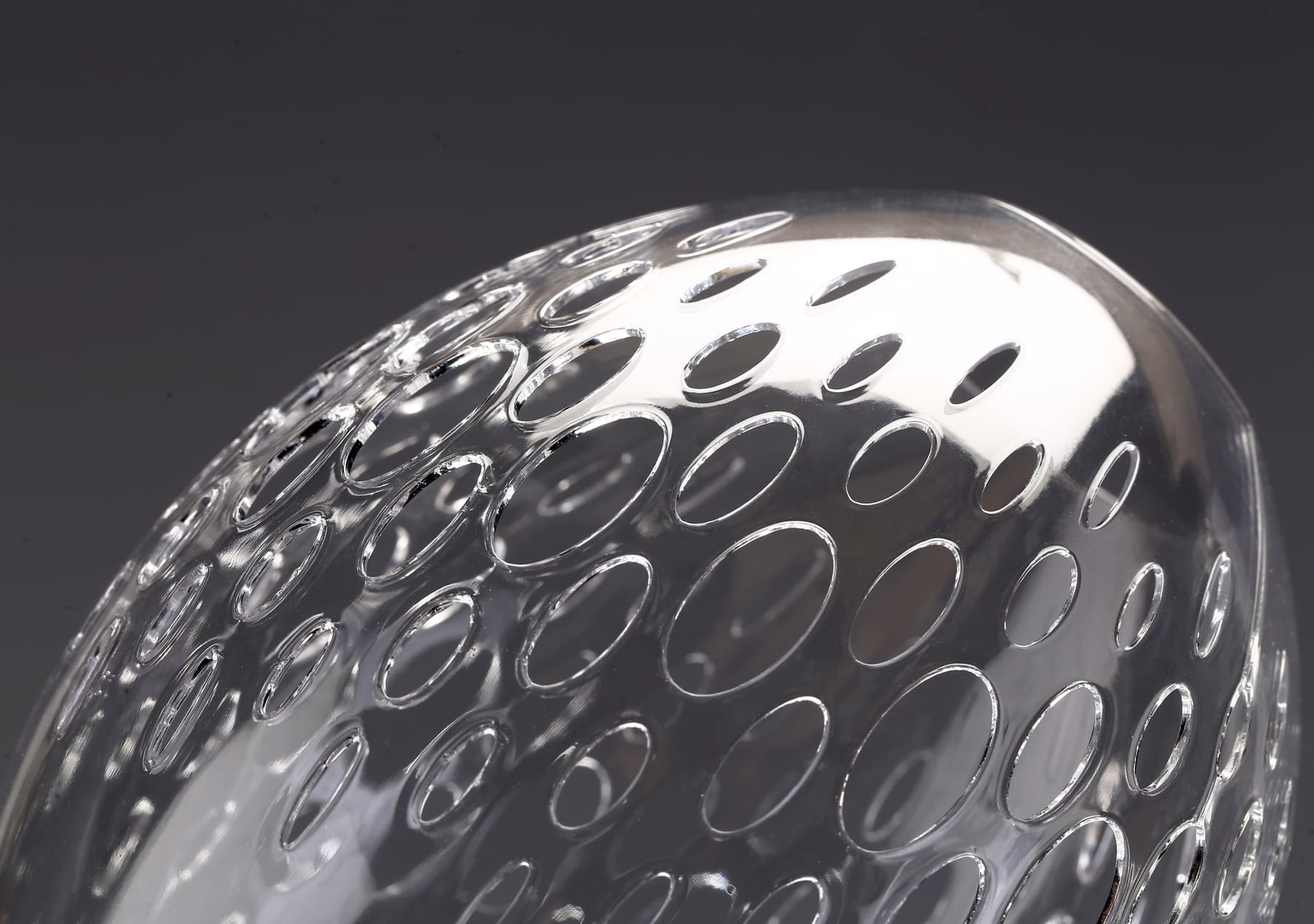

For this project, BizLink Healthcare was developing a new medical imaging device. The specific need was for an internal wiring component, a part that would help route and organize cables within the imaging system. While seemingly simple, this component had to meet strict requirements for flexibility, durability, and dimensional accuracy.

BizLink Healthcare turned to 3DSPRO to ensure that the part could be produced with the right material, tested for performance, and refined to meet the standards of medical device manufacturing.

Image Copyright © 3DSPRO Limited. All rights reserved.

Decoding the Technical Requirements

From the outset, the requirements for the component were clear and uncompromising. BizLink Healthcare emphasized three critical factors:

• Flexibility: The component needed to bend and adapt to the internal structure of the imaging device without cracking or losing integrity.

• Durability: It had to withstand compression and stress during assembly and operation, ensuring long-term reliability.

• Zero Brittleness: Any tendency toward brittleness would risk fracture under normal use, which was unacceptable in a medical context.

In addition to mechanical performance, the client also expressed a preference for material transparency. A translucent finish would allow easier inspection of internal wiring and contribute to the overall design of the imaging system.

Image Copyright © 3DSPRO Limited. All rights reserved.

Material Specifications and Requirements

Unlike many projects where 3DSPRO guides clients through material selection, in this case, BizLink Healthcare came with a clear specification: Flexible 80A Resin.

Flexible 80A Resin was chosen for its unique combination of properties:

• Translucency: While not clear, it offered a semi-translucent finish that aligned with the client’s preference.

• Elasticity: Its ability to flex without breaking made it suitable for components that would undergo bending and compression.

• Toughness: The resin’s resilience under stress ensured that the part could withstand normal mechanical loads without failure.

3DSPRO’s role was to execute production using this material, ensuring that the printed component met the client’s expectations for both performance and finish.

Image Copyright © 3DSPRO Limited. All rights reserved.

Production Excellence

The component was produced using LCD 3D printing service at 3DSPRO, a process well-suited for resin materials that require fine detail and dimensional accuracy.

The workflow included:

1. Printing: Layer-by-layer construction of the component using Flexible 80A Resin.

2 Cleaning: Removal of excess resin to prepare the part for curing.

3. Curing: Exposure to controlled light and heat to solidify the resin and achieve its final mechanical properties.

Image Copyright © 3DSPRO Limited. All rights reserved.

Post Processing

Post-processing is a critical step in resin printing, especially for medical components where precision and finish matter. For this project, 3DSPRO focused on two essential tasks:

1. Support Removal: Internal supports generated during printing were carefully removed. This step was vital to achieving smooth surfaces and dimensional accuracy, preventing interference with wiring or assembly inside the imaging device.

2. Curing: Ensuring the resin achieves its full mechanical strength and elasticity. Proper curing was essential to confirm that the part would perform reliably under stress.

By limiting post-processing to these focused steps, 3DSPRO ensured efficiency while maintaining the integrity of the component. The part was now ready for functional testing.

Testing and Validation

With post-processing complete, 3DSPRO conducted manual stress tests to validate the component’s performance. These tests were designed to simulate the conditions the part would face during assembly and operation:

• Bending Tests: The component was flexed repeatedly to confirm that it could bend without cracking or losing elasticity.

• Compression Tests: Pressure was applied to simulate assembly stress and operational loads.

The components maintained flexibility, resisted compression, and showed no signs of brittleness or fracture during the tests. These outcomes confirmed that the part met BizLink Healthcare’s mechanical requirements and was suitable for integration into the imaging device.

Communication and Collaboration

Throughout the project, 3DSPRO prioritized transparent communication with BizLink Healthcare.

• Color Variation: The yellowish tint observed during curing was reported promptly. The client confirmed that mechanical performance was the priority, and the aesthetic variation was acceptable.

• Testing Results: Performance outcomes were shared clearly, reinforcing confidence in the component’s reliability.

• Responsiveness: By addressing issues proactively and aligning with client priorities, 3DSPRO strengthened trust and demonstrated its commitment to partnership.

Image Copyright © 3DSPRO Limited. All rights reserved.

Outcomes

3DSPRO delivered production-ready components that integrated seamlessly into BizLink Healthcare's imaging device. The parts met all dimensional tolerances and mechanical specifications, enabling the client to proceed with device assembly without delays or modifications. The project ultimately showcased how 3DSPRO's LCD 3D printing service can address complex medical device challenges through technical expertise, quality control, and professional project management.

COMMENTS

- Be the first to share your thoughts!