Yotta Energy x 3DSPRO

• Solar Energy Solution Expert: Yotta Energy

• 3D Printing Solution Provider: 3DSPRO

• Product: Solar Energy Storage System

Yotta Energy is an innovative company dedicated to revolutionizing the solar energy sector with advanced energy storage solutions. They aim to make solar power more efficient, reliable, and accessible, thereby contributing to a more sustainable future. With a focus on integrating solar energy and storage systems, Yotta Energy provides versatile solutions that cater to diverse energy needs.

The collaboration between Yotta Energy and 3DSPRO exemplifies how advanced 3D printing technologies can be leveraged to create high-quality components for solar energy systems. The scope of the project was extensive, covering the production of a wide range of parts, from the main chassis to various smaller components. The partnership enabled the completion of most of the product's key components.

Throughout the process, 3DSPRO addressed Yotta Energy's specific requirements by using different materials and techniques to conduct fit and function tests. The iterative processes allowed for continuous customization and refinement, ensuring that the final products met the highest standards of quality and performance.

The main aspects of the collaboration included the production of three crucial components:

• Chassis: The primary structure of the product, manufactured using metal 3D printing and post-processed with powder coating.

• Chassis Sealing Gaskets: Produced through SLA 3D printing and vacuum casting to ensure precise fit and durability.

• Other Spare Parts: Created using SLA and SLS 3D printing technologies with multiple materials, providing high precision and reliability.

Overall, 3DSPRO employed a variety of manufacturing and post-processing technologies to meet Yotta Energy's specific needs, including metal 3D printing, SLA 3D printing, SLS 3D printing, vacuum casting, and powder coating (for metal parts), ensuring that each component was optimized for its specific application to provide the best performance.

In the following sections, we will delve deeper into how 3DSPRO and Yotta Energy worked together for this project.

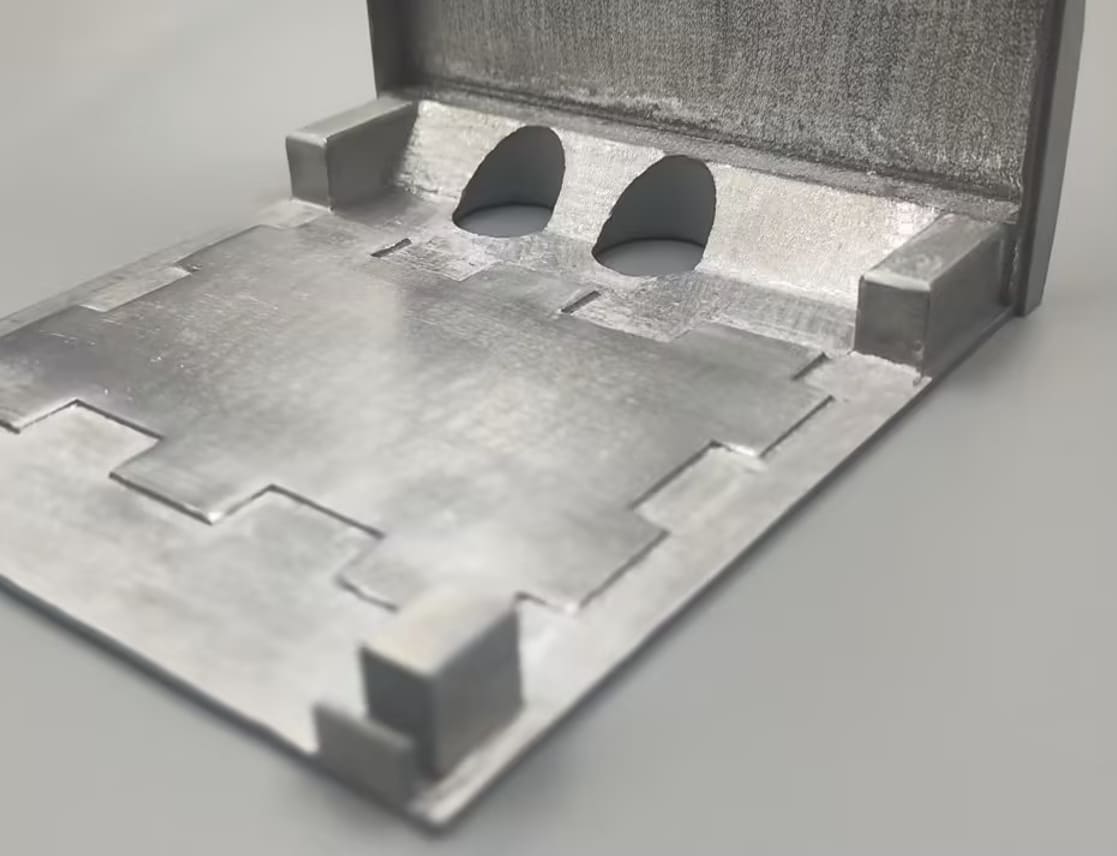

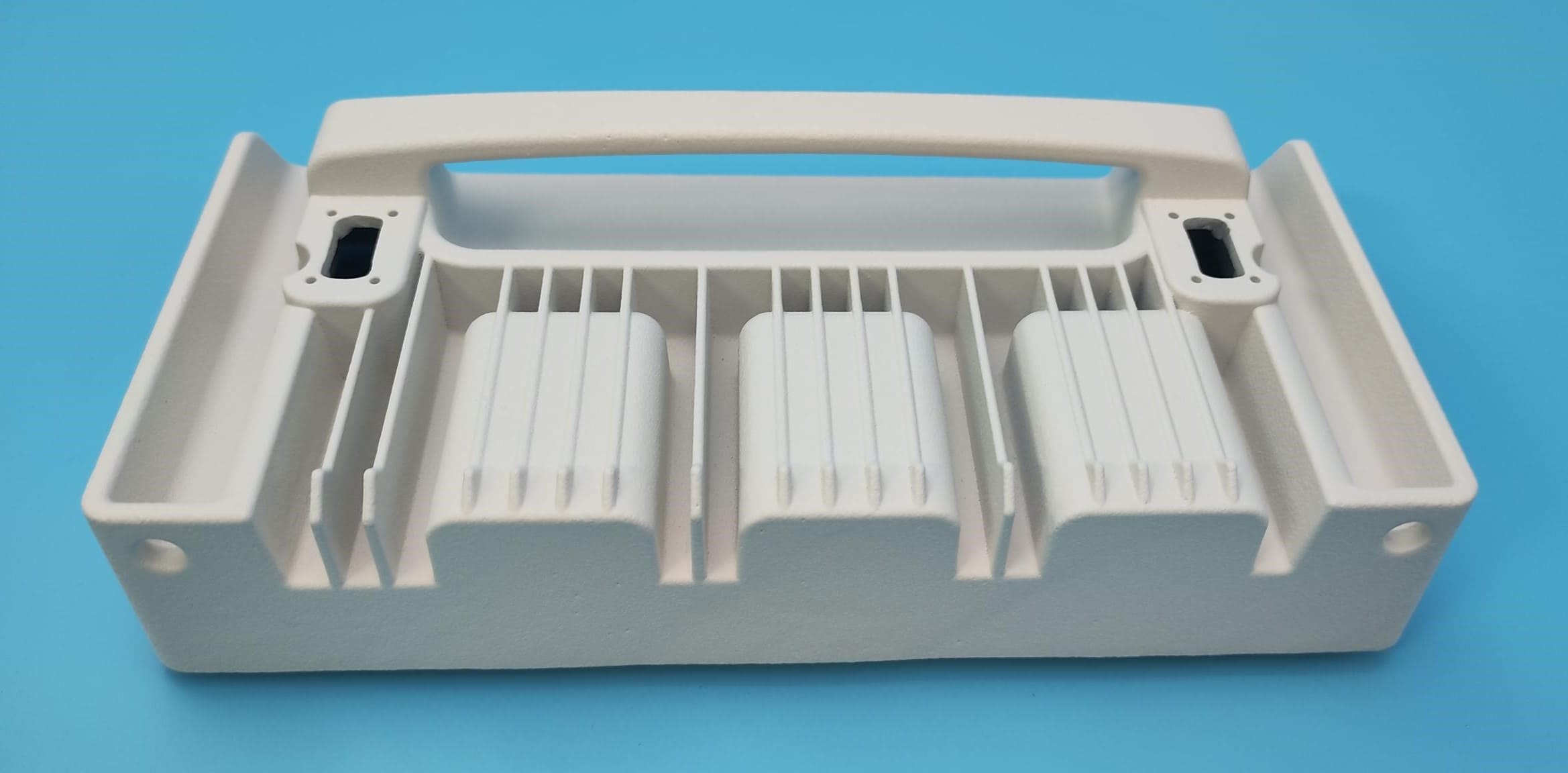

Metal 3D Printing and Powder Coating for the Chassis

• Yotta Energy Requirements: Durable, Airtight and Aesthetic

• 3DSPRO Solutions: Metal 3D Printing, Power Coating

• Materials: AlSi10Mg

To meet the requirements for a durable, airtight, and aesthetically pleasing chassis, 3DSPRO delivered advanced metal 3D printing, specifically selective laser melting (SLM 3D Printing) and powder coating techniques. Using AlSi10Mg, a high-strength aluminum alloy known for its excellent mechanical properties and good thermal conductivity.

Besides, the chassis feature complex geometric designs optimized for mechanical and electronic applications, including intricate parallel fins for heat dissipation, precise mounting holes for component integration, and a combination of rectangular and hexagonal cutouts to accommodate various functional requirements. The chassis' precise and detailed structure exemplifies the capabilities of metal 3D printing in producing highly functional and robust components. The material's inherent properties contributed to the overall durability and structural integrity of the chassis.

To achieve an airtight finish and enhance the visual appeal of the parts, we applied a high-quality powder coating. Powder coating provided a smooth, attractive surface and added an extra layer of protection against environmental factors, thus ensuring the longevity and reliability of the chassis.

By integrating these advanced manufacturing techniques, 3DSPRO delivered a chassis that perfectly aligned with Yotta Energy's specific requirements for the chassis.

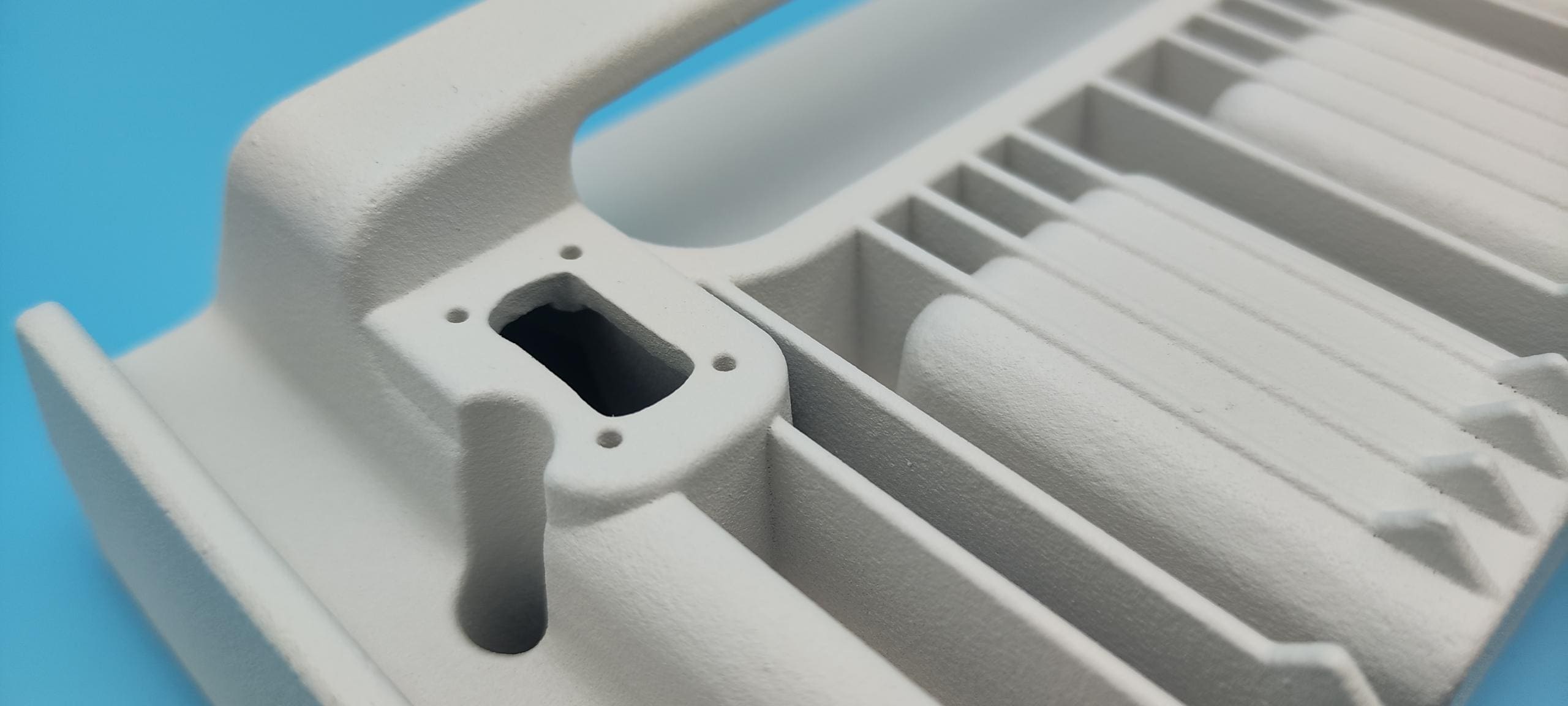

SLA 3D Printing and Vacuum Casting for the Chassis Sealing Gaskets

• Yotta Energy Requirements: Flexible and Precise

• 3DSPRO Solutions: SLA 3D Printing, Vacuum Casting

• Materials: Quality Resin White

To create flexible and precise chassis sealing gaskets for Yotta Energy, 3DSPRO employed a combination of SLA 3D printing and vacuum casting.

Utilizing high-quality resin white, SLA 3D printing allowed us to produce highly detailed and accurate master models of the gaskets. The process ensures high precision of the 3D-printed gaskets, which are required for an airtight seal.

After accurately 3D printing the master model, we use vacuum casting to replicate the gaskets in a flexible and durable resin, which ensures that each gasket maintains the exact size and flexibility for optimal performance of the chassis. Vacuum casting also allows for the efficient production of multiple gaskets, ensuring consistent and high quality across all units.

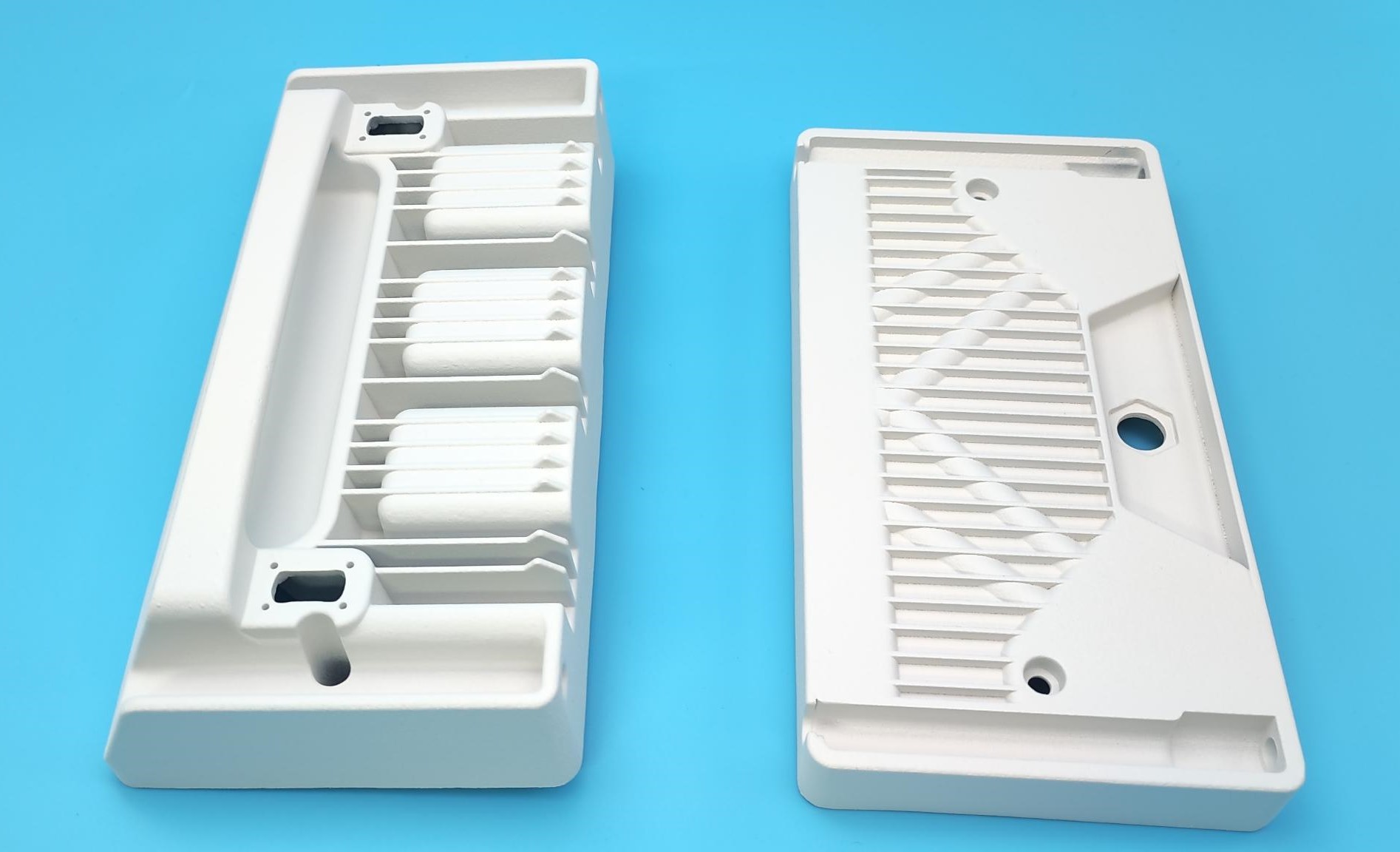

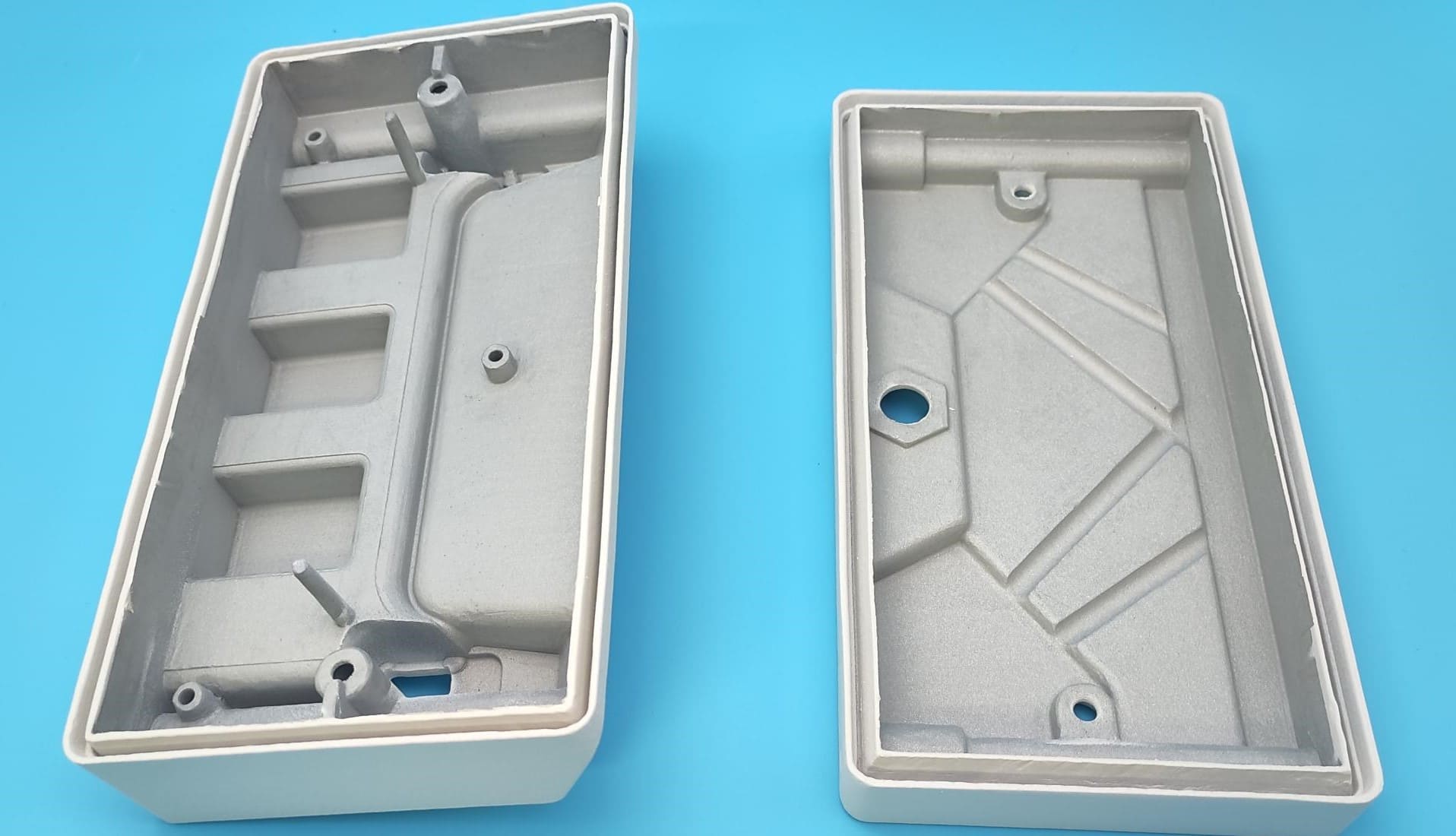

SLA and SLS 3D Printing for the Spare Parts

• Yotta Energy: Try different materials to figure out the best one.

• 3DSPRO Solutions: SLA 3D Printing, SLS 3D Printing

• Materi• TPU White, PA 12 White, PA 12 Black, High-Detailed Resin White, Quality Resin White

Yotta Energy aimed to experiment with different materials to achieve the best custom fit and functionality for their spare parts. To support this, 3DSPRO delivered SLA and SLS 3D printing solutions. We tested a variety of materials, including TPU White, PA 12 White, PA 12 Black, High-Detailed Resin White, and Quality Resin White.

SLA 3D printing offers high precision and fine detail, making it ideal for parts that require complex features. On the other hand, SLS 3D printing provides strong and durable parts suitable for functional testing. We helped Yotta Energy evaluate the performance, compatibility and suitability of different materials for their specific application.

By leveraging our advanced 3D printing capabilities, we provide high-quality spare parts and help Yotta Energy find the best material for the custom fit and function of each component.

Customizable and Customer-Centric Services

Our team worked closely with Yotta Energy from the initial consultation to the final production phase, ensuring that every step of the process met their goals. We utilized advanced 3D printing technologies, including SLA, SLS, and metal 3D printing, to produce a variety of parts that were critical to their project.

By prioritizing customization and customer satisfaction, 3DSPRO successfully delivered high-quality and reliable parts. We are committed to serving our clients every step of the way, ensuring their needs are met with precision and care.

COMMENTS

- Be the first to share your thoughts!