NUA and Lazy Snail x 3DSPRO: Teamed up to Create Premium Food Packaging

What We Made

● Saudi Dates Brand: NUA

● Packaging Designer: Lazy Snail

● Packaging Manufacturer (Metal Parts): 3DSPRO

NUA and Lazy Snail partnered with 3DSPRO to create exceptional food packaging for Saudi dates. The project features three unique packaging designs: Dunes ans Stem. Dunes and Stem are the winners of Pentawards 2024.

Saudi dates brand NUA worked with packaging designer Lazy Snail and manufacturing service provider 3DSPRO, who were responsible for the metal components of the packaging. Utilizing additive manufacturing for the initial prototypes and conventional manufacturing techniques for the serial batches, the collaboration ensured a seamless blend of innovation and craftsmanship.

These award-winning packages highlight the ability to merge advanced manufacturing technologies with exquisite design to produce premium food packaging that is both functional and aesthetically pleasing.

Dunes

Project Timeline

On September 20, 2023, Lazy Snail reached out to 3DSPRO via email with a request for prototypes and serial batches of 20 pieces each for the Dunes and Stem packaging designs. They emphasized the need for high, consistent quality, excellent surface finish, and an urgent lead time.

3DSPRO quickly responded and, within 20 days, despite the complexity of the products, successfully produced the requested metal components. By October 11, 2023, the prototypes and serial batches were completed.

On October 20, 2023, Lazy Snail and NUA received 50 pieces each of the Dunes and Stem packaging. During this meeting, 3DSPRO provided a detailed demonstration and explanation of the metal components, showcasing their quality and craftsmanship.

This timeline illustrates our project management capability to deliver high-quality, complex products within tight deadlines, ensuring customer satisfaction through efficient production and excellent service.

Stem

How We Worked Together

The collaboration between NUA, Lazy Snail, and 3DSPRO was a seamless blend of creative vision and technical expertise. From the outset, clear communication was established, ensuring that all stakeholders were aligned on the project goals and requirements. Lazy Snail provided detailed design specifications and quality standards, which 3DSPRO meticulously followed to ensure the highest quality prototypes and serial batches.

Throughout the process, regular updates and feedback loops were maintained, allowing for any necessary adjustments to be made promptly. This iterative approach helped in fine-tuning the designs and overcoming any technical challenges that arose. Our advanced manufacturing capabilities and commitment to excellence enabled the efficient production of complex components, meeting the urgent timelines set by Lazy Snail and NUA.

Custom Manufacturing Solutions for Specific Products

Design Concepts

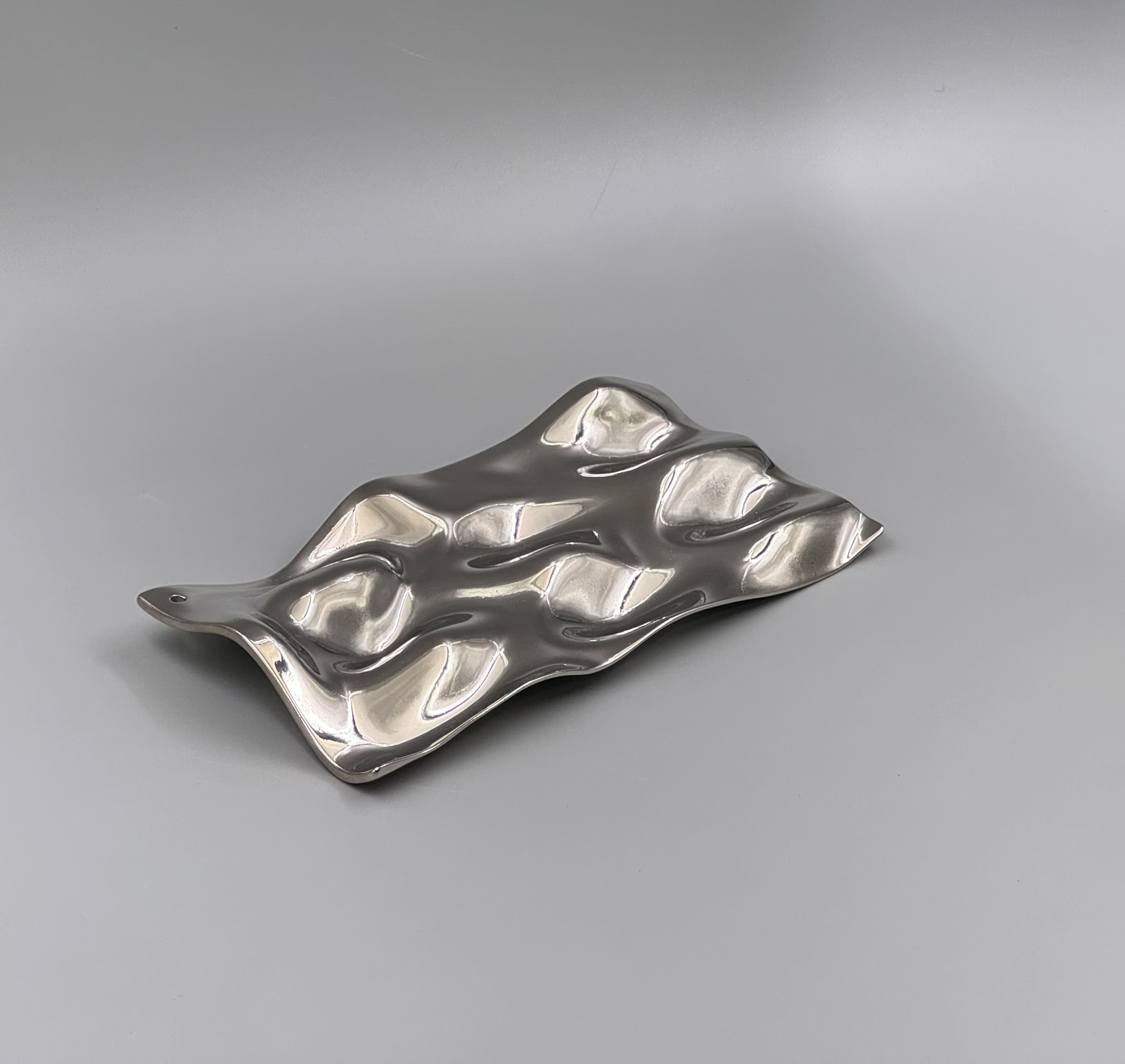

Dunes

The Dunes packaging design draws inspiration from the Saudi Arabian desert landscape, featuring soft ripples of sand translated into a continuous, curvaceous form of mirrored polished stainless steel. This design not only preserves the freshness of dates but also serves as both a storage item and a presentation object. The combination of walnut wood and a lustrous tray symbolizes Saudi heritage and innovation.

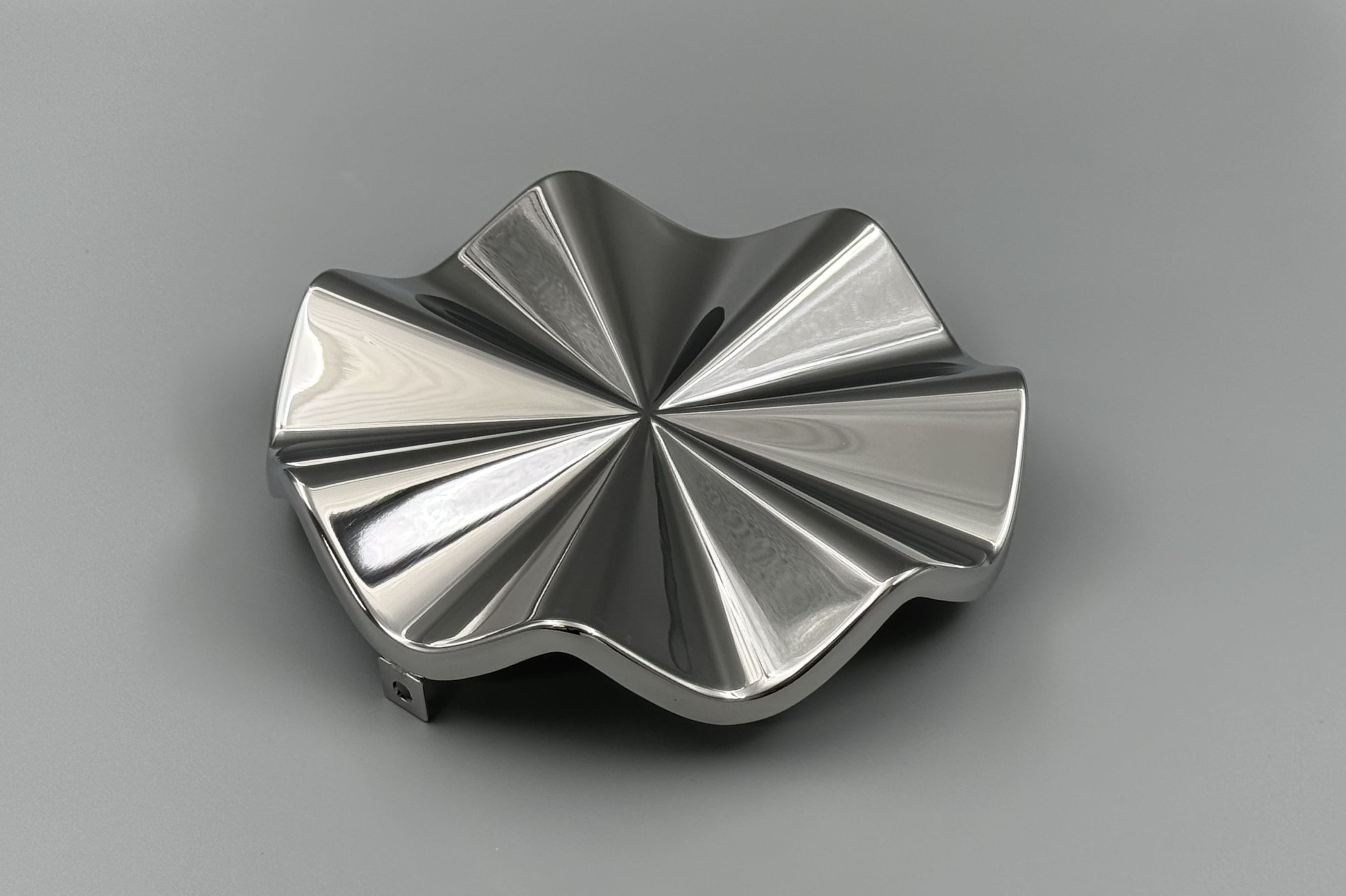

Stem

Inspired by the Saudi Arabian date palm, Stem's packaging design features modular, stackable candy boxes with round bowls that represent the tree's trunk and the iconic diamond leaf pattern. The design symbolizes the symbiotic relationship between humans and nature, blending warm walnut wood with polished stainless steel to create a luxurious aesthetic. Designed for both storage and display, Stem highlights the careful selection process of NUA dates.

Manufacturing Solutions for Prototypes of Dunes and Stem

● Additive Manufacturing: Selective Laser Melting (SLM 3D Printing)

● Material: Stainless Steel 316L

● Post-processing: Mirror Polishing

For the prototypes of the packaging, we utilized metal 3D printing, specifically Selective Laser Melting (SLM). SLM technology is adept at producing complex geometries, such as the Dunes prototype, which features intricate ripples and flat surfaces.

For food safety, we selected stainless steel 316L, known for its excellent biocompatibility and corrosion resistance, making it an ideal material for food packaging. Besides, despite the internal stresses inherent in the part that made it prone to deformation, we overcame these challenges by meticulously adjusting the printing parameters, including orientations, printing efficiency, layer thickness, etc. This required close collaboration with Lazy Snail to iterate on the design and ensure optimal results.

After printing, the prototypes underwent mirror polishing as a post-processing step to achieve the shiny and smooth surface finish requested by our clients.

However, upon successfully producing the metal parts for the packaging, we encountered some issues. The metal 3D printed prototypes were quite heavy due to the high density of 316L. Additionally, pockmarks still exist even after mirror polishing was present on the surface. These factors meant the prototypes did not meet the quality standards required for serial batches.

Consequently, we developed a custom and specific manufacturing solution for the serial production, ensuring all requirements were met and maintaining the high standards of quality and aesthetics expected by our clients.

Manufacturing Solutions for Serial Batches of Dunes and Stem

● Conventional Manufacturing: Stamping, CNC Machining

● Material: Stainless Steel 316L

● Post-processing: Polishing and OVD Coating

For the serial batches of the packaging, we chose conventional manufacturing methods to ensure efficiency, precision, and consistency.

For the Dunes packaging, stamping was employed to form the metal parts, perfectly capturing the intricate ripple designs. This method provided consistency and high-quality surface finishes across the batch.

The Stem packaging required a combination of stamping and CNC machining. Stamping was used to create the metal parts, while CNC machining was employed for the finer details and screws. This dual approach ensured the accuracy and modularity needed for the stackable design elements.

Each specific manufacturing solution ensured that each packaging design was produced with the highest standards of quality, maintaining the intricate details and aesthetic appeal envisioned by Lazy Snail and NUA.

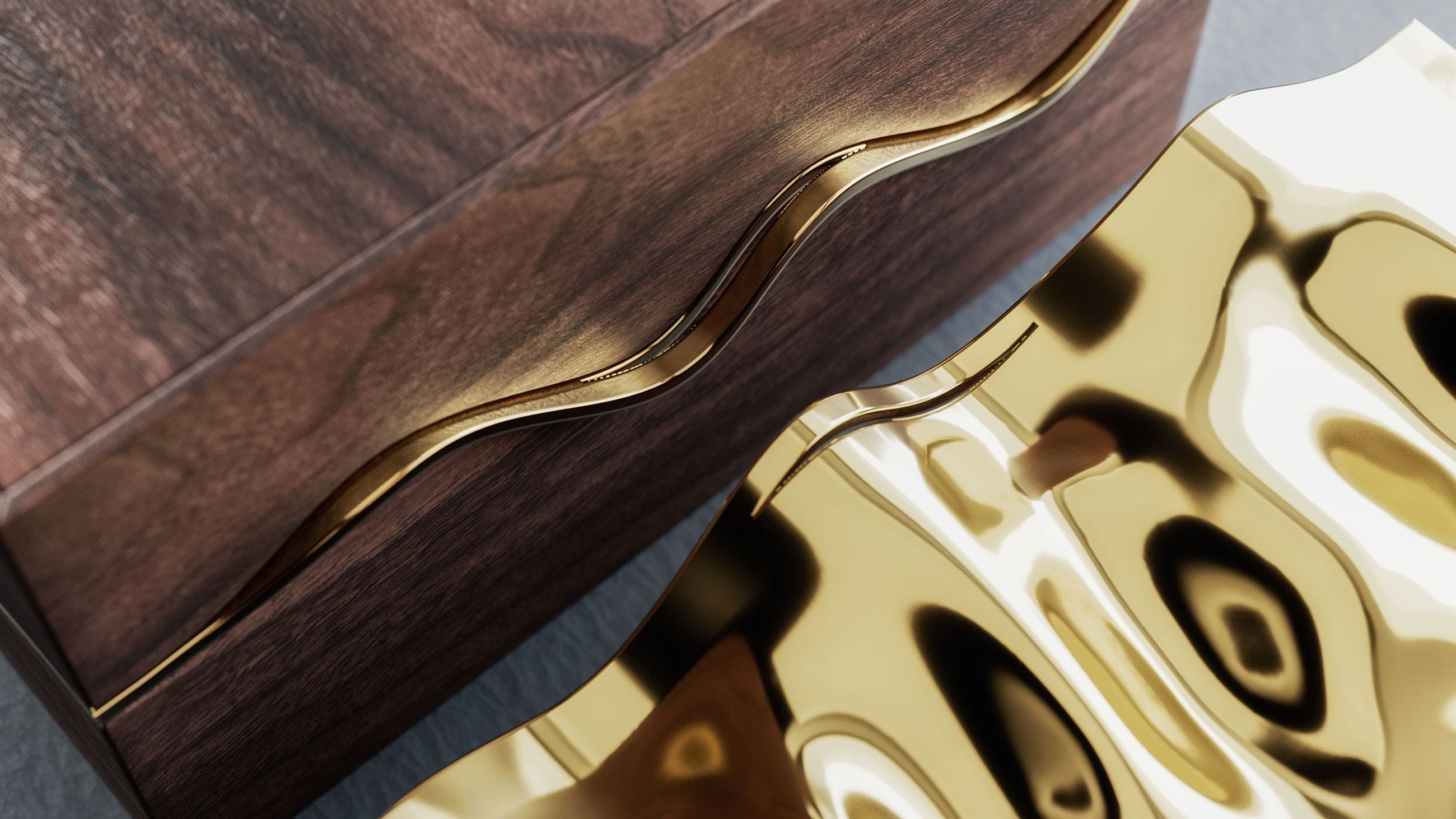

For the material, all the batches used 8K mirrored stainless steel 316L, which is durable, biocompatible, and resistant to corrosion, making it a perfect material for food packaging. Besides, stamped 316L steel is lightweight, smooth, and glossy. This material provided both the necessary structural integrity and the desired high-quality finish.

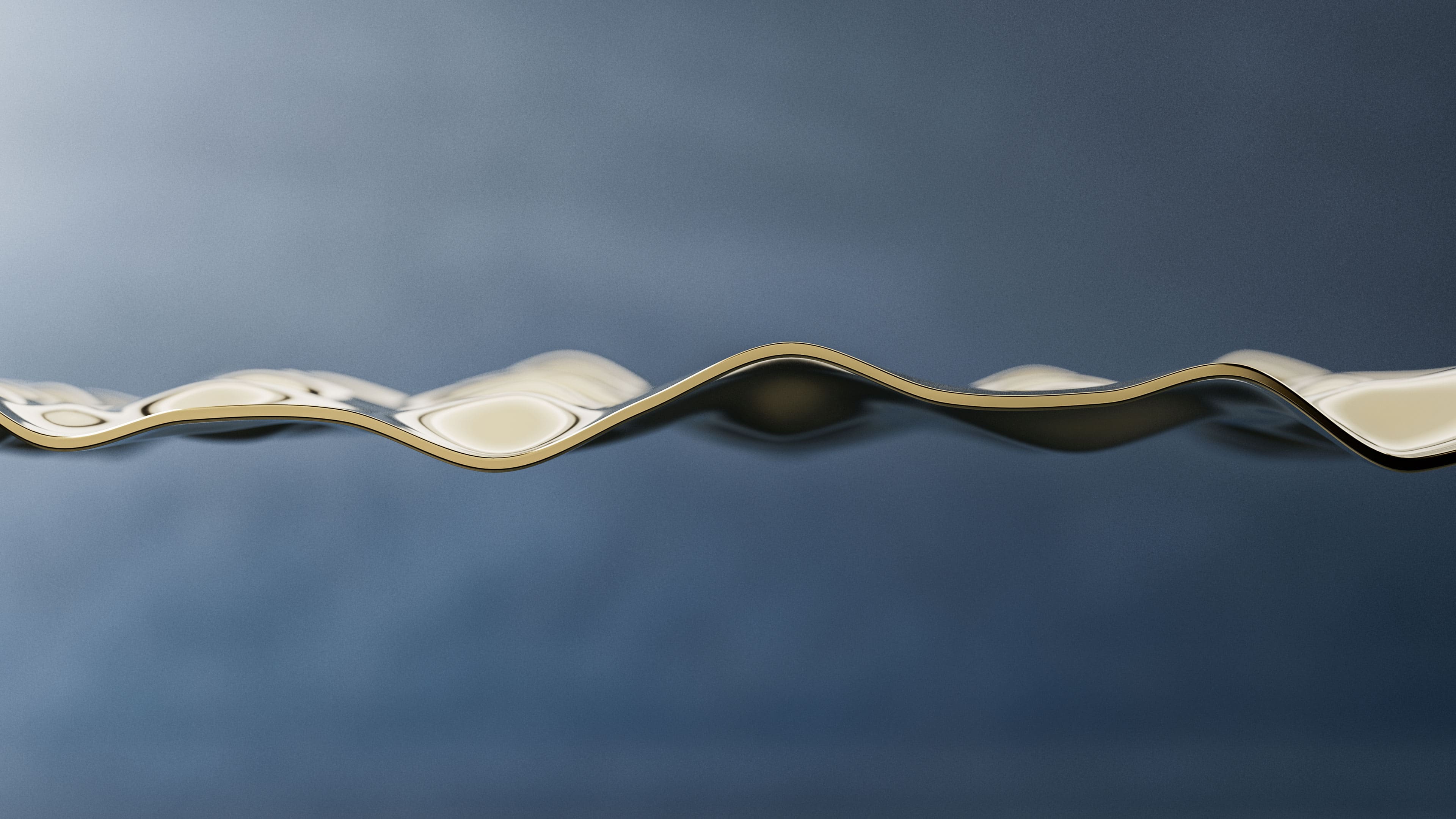

Post-processing involved meticulous polishing to enhance the surface smoothness and prepare it for the final coating. We applied PVD (Physical Vapor Deposition) titanium coating with a custom gold color. This advanced coating technique added a luxurious golden finish, which is durable and does not easy to leave scratches on the surface.

Before PVD Titanium Coating:

After PVD Titanium Coating:

The custom manufacturing solution for serial production not only addressed the challenges faced during the prototype phase but also delivered serial batches with consistent quality, reduced weight, and an impeccable surface finish, exactly as customers require.

Customer-centric Services

Additive Manufacturing for Prototypes

3DSPRO excels in additive manufacturing, meeting customer needs with precision and expertise. For this project, we used metal 3D printing to create the prototypes, specifically through Selective Laser Melting (SLM) technology. SLM 3D printing allowed us to capture intricate designs and complex geometries accurately. Following the printing process, we applied mirror polishing to achieve a sleek and reflective surface finish.

However, we encountered surface pockmarks on the prototypes, which could not be completely eliminated even through mirror polishing. Recognizing that this did not meet the stringent quality standards required for serial batches, we proactively sought out more optimal solutions.

Our commitment to quality and customer satisfaction drove us to explore and implement alternative manufacturing methods, ensuring that the final products would meet and exceed expectations.

Conventional Manufacturing for Serial Batches

Given the high surface quality requirements and the need for consistent quality across serial batches, we decided to utilize conventional manufacturing techniques.

These included stamping and CNC machining, combined with polishing and PVD coating to achieve the desired finish, ensuring that each product was flawlessly executed, with 50 pieces produced for each design.

Notably, the Dunes and Stem packaging received prestigious recognition, winning the 2024 Pentawards and the 2024 iF Design premium packaging design.

3D Scanning for Fitting

Beyond metal, the remaining components of these date packaging designs are crafted from wood and marble, created by our clients' partners. Ensuring precision and seamless integration between these materials and the metal parts posed a challenge due to the differing properties of wood and marble, which can make achieving perfect fitment more difficult.

To solve this problem, we used 3D scanning technology, which allowed us to accurately measure and understand how to align the metal, wood, and marble components perfectly.

These adjustments ensured a harmonious fit and also took ergonomic considerations into account, making the packaging both beautiful and user-friendly, aiming to create a pleasant and practical experience for the end user.

Empowering Our Customers for Success

Award-Winning Food Packaging

At 3DSPRO, we take immense pride in the success of our clients. The Dunes and Stem packaging designs are shining examples of our capabilities, having won awards such as the iF Design and the Pentawards 2024. These honors highlight our commitment to design and manufacturing excellence and our ability to deliver products that stand out in a competitive marketplace.

Communications

Effective communication is at the core of our operations. We prioritize prompt and clear communication, whether through emails, phone calls, WhatsApp messages, or other channels, ensuring their needs and concerns are addressed quickly. This dedication to fast and efficient communication fosters strong client relationships and ensures projects run smoothly from inception to completion.

Project Management

Our strong project management practice is designed to handle complex projects with precision and efficiency. We use a structured approach that includes detailed planning, ongoing monitoring, and timely execution to ensure we meet deadlines, stay within budget, and deliver high-quality results that exceed our clients’ expectations.

International Cooperation and Sourcing

Our global network enables us to source the best materials and technologies from around the world. We work with international partners to provide our clients with innovative solutions, ensuring they have access to cutting-edge manufacturing technologies and the highest quality resources. Our expertise in international collaboration and sourcing enables us to handle projects of any size and complexity, providing our clients with a competitive advantage.

We are committed to helping our customers thrive by providing unparalleled support and innovative solutions tailored to their unique needs.

COMMENTS

- Be the first to share your thoughts!