What is sandblasting?

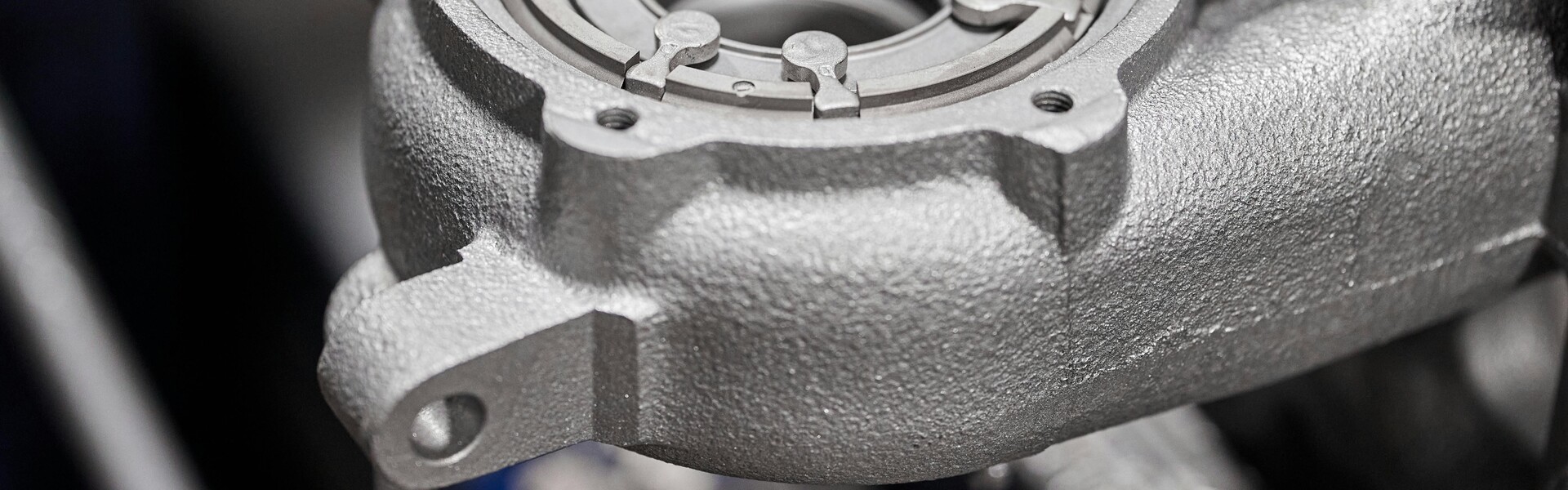

Sandblasting is a process that cleans and smoothens surfaces by propelling abrasive particles at high velocity using compressed air.

Sandblasting removes rust, paint, and other contaminants from various materials, including metal, wood, and plastic. It's widely used in industrial settings to prepare surfaces for painting or coating, ensuring a clean and even finish.

Sandblasting can also be employed to create decorative textures or etch patterns onto surfaces.