What is translucency?

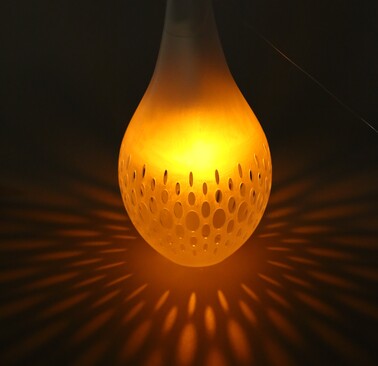

Translucency refers to the ability of the resin material to allow light to pass through it, but not clearly enough to see distinct shapes or details on the other side.

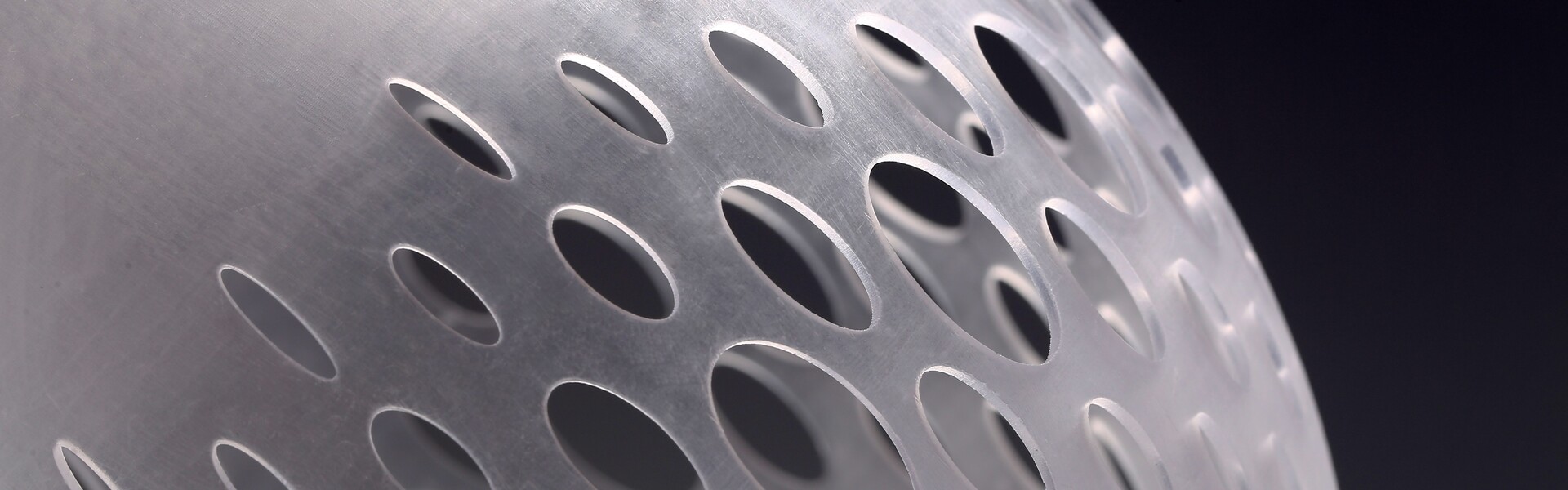

The translucent effect is achieved by carefully sanding, polishing, and applying clear coatings to the resin prints.

Translucency enhances the visual appeal of 3D printed objects, creating a smooth, glass-like finish that can be used for decorative items, prototypes, and functional parts that require a semi-transparent appearance.