What is threading?

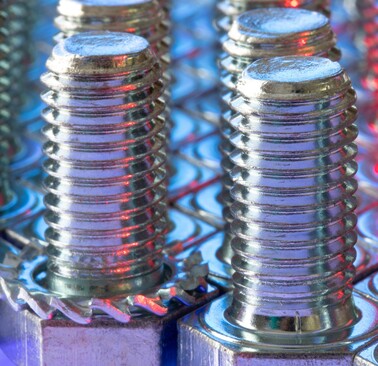

Threading in 3D printing post-processing involves creating screw threads on 3D printed parts to allow them to be securely assembled with other components.

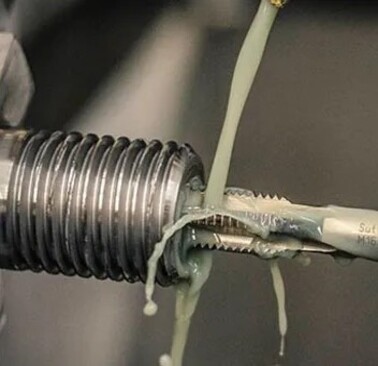

Threading can be done internally (inside a hole) or externally (on a shaft). Special tools like taps and dies are used to cut the threads precisely.

It adds functionality and structural integrity to 3D printed parts, making them suitable for mechanical and structural applications where secure connections are required.