3D Modes for Testing Your 3D Printer

Before delving into specific model designs, it’s important to understand that “test 3D models” are purpose‑built prints used to evaluate and fine‑tune every aspect of a 3D printer’s performance, from dimensional accuracy and extrusion consistency to thermal control and mechanical precision. By running these quick, small‑scale benchmarks regularly, we gain actionable data on 3D printers' current health, catch drift in calibration parameters early, and maintain consistent print quality over time. Ultimately, integrating routine test prints into your workflow saves time and material, prevents costly failures on critical parts, and ensures reliable, repeatable results across different materials and geometries.

What Are Test 3D Models?

Test 3D models consist of a range of simple to complex geometries—cubes, towers, torture‑tests, and multi‑feature benchmarks—specifically designed to stress different printer subsystems (motion, extrusion, cooling, and slicing) in isolation. Unlike arbitrary functional parts, these models include calibrated dimensions, overhang angles, bridges, retraction sequences, and thermal gradients so that deviations from expected outcomes directly point to underlying issues. For example, dimensional accuracy tests (like the XYZ calibration cube) verify steps‑per‑millimetre settings on X, Y, and Z axes, while temperature towers pinpoint the optimal extrusion and bed temperatures for a given filament.

Benefits of Regular Testing

1. Enhanced Print Quality & Consistency

Routine test prints help you identify and correct calibration drift—axis steps, extrusion multipliers, and Z‑offset—before they manifest as layer misalignments, dimensional errors, or adhesion failures. Benchmarks also reveal material‑specific quirks (warping, stringing, layer adhesion) so you can establish slicer profiles that yield reliable, repeatable results across batches.

2. Time and Cost Savings

By catching mechanical or slicing issues on small models, you avoid failed large‑scale prints that waste hours of machine time and meters of filament. Early detection of nozzle clogs, cooling fan deficiencies, or belt tension problems through quick test prints prevents catastrophic failures mid‑print, saving both material and troubleshooting time.

3. Informed Troubleshooting

When a test model fails—whether due to ghosting, under‑extrusion, or poor overhang performance—the structured nature of these prints isolates the variable at fault (e.g., motion system versus thermal management), allowing targeted adjustments rather than blind trial and error.

4. Optimized Material and Temperature Settings

Temperature calibration towers and filament‑specific test models reveal the precise melting and bonding characteristics of each material, reducing warping, stringing, and poor layer adhesion in production parts and ensuring that each filament runs at its sweet spot, maximizing performance and longevity.

5. Preventative Maintenance & Machine Health

Regularly integrating test prints into your maintenance schedule functions as a diagnostic health check: it flags emerging mechanical wear—belt stretch, bearing play, extruder slip—before it degrades print quality or causes printer downtime.

Download Test 3D Models for Free

1. 3D Benchy

The 3DBenchy is a purpose‑designed 3D model shaped like a tugboat that serves as the industry-standard calibration and benchmarking tool for FFF/FDM printers. Created by Creative Tools and released in April 2015, its geometry incorporates critical features—overhangs, bridges, fine text, and planar surfaces—that expose artifacts such as surface deviations, layer shifting, and first‑layer squashing. Due to its comprehensive design, rapid print time, and ease of measurement, it’s widely regarded as the most‑printed object and is included out‑of‑the‑box on many printers. Its ubiquity and diagnostic power make 3DBenchy an essential first print for verifying dimensional accuracy, extrusion consistency, and cooling performance before tackling complex or critical projects.

Image Source: 3D Print Concepts (MakerWorld)

2. XYZ Cube

The XYZ Cube is a calibration model labeled on each face to denote the X, Y, and Z axes, designed to verify dimensional accuracy and identify axis-specific errors in your printer’s motion system. By printing the cube and measuring each side with digital calipers, you can uncover and correct steps-per-millimeter offsets, belt tension irregularities, and flow rate discrepancies before committing to larger, critical prints. Its compact size and simple geometry allow rapid diagnostics, while exposing layer height inconsistencies, extrusion variations, and directional artifacts. Many variants include embossed axis labels and optional bridging features, also to test overhang performance and stringing tendencies.

Image Source: hectorri (MakerWorld)

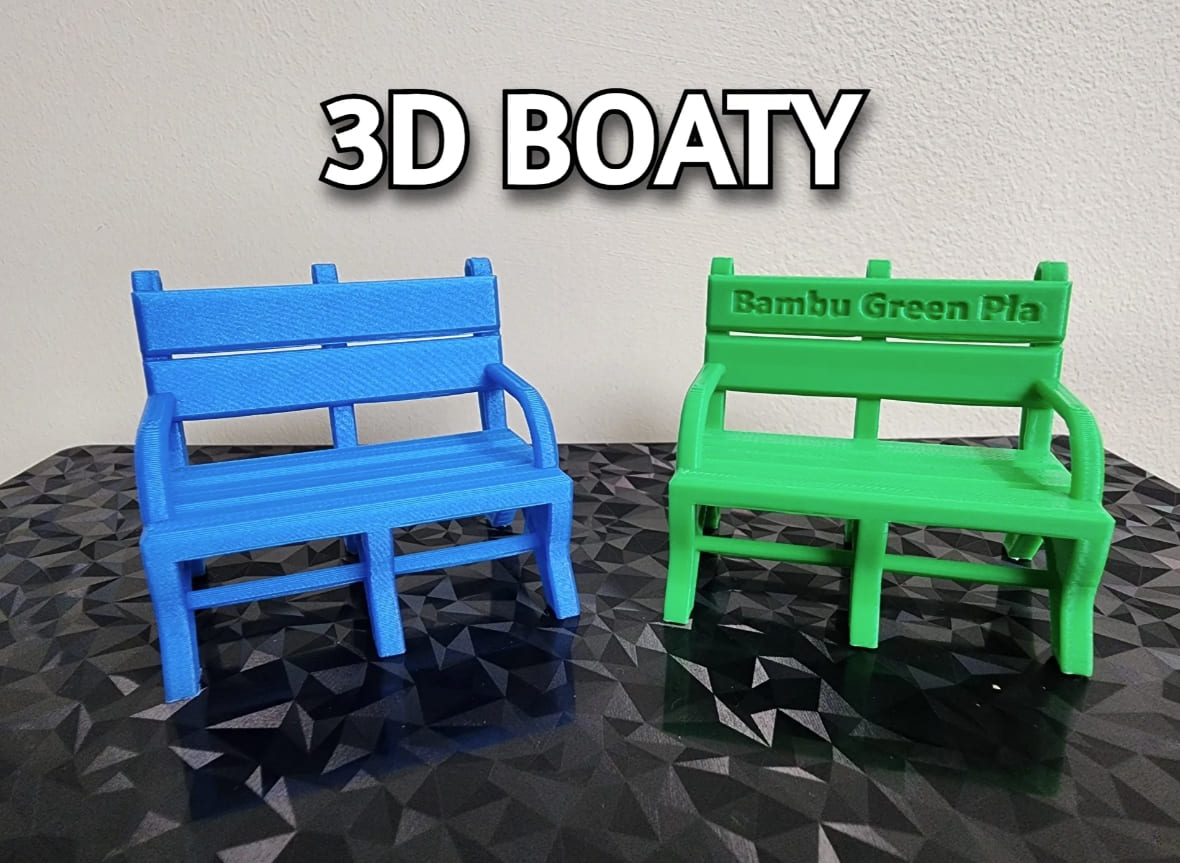

3. 3D Boaty

3D Boaty is a compact benchmarking model for FFF/FDM printers that enables rapid diagnostics with minimal material cost. Its boat silhouette integrates typical print challenges—overhangs, bridging spans, thin walls, and fine surface details—so you can evaluate cooling efficiency, extrusion consistency, and dimensional accuracy in one swift print. Its small footprint and diagnostic breadth make 3D Boaty an ideal first print for calibrating new machines, validating fresh filament batches, or performing routine health checks before embarking on complex or large‑scale projects.

Image Source: depep1 (MakerWorld)

4. PolyPearl Tower

The PolyPearl Tower is a torture‑test model introduced by Polymaker to push both your 3D printer and filaments to their absolute limits. Its multi‑feature design incorporates tight curvature, overhangs, fine pillars, and varied bridge spans, exposing weaknesses in cooling performance and extrusion flow. Users can employ calipers to measure the diameter of the tower’s “pearls,” precisely quantifying filament expansion and flow rate deviations. Whether calibrating a new machine, validating a fresh filament batch, or performing routine maintenance, the PolyPearl Tower delivers a comprehensive health check in under an hour.

Image Source: Polymaker_3D (Thingiverse)

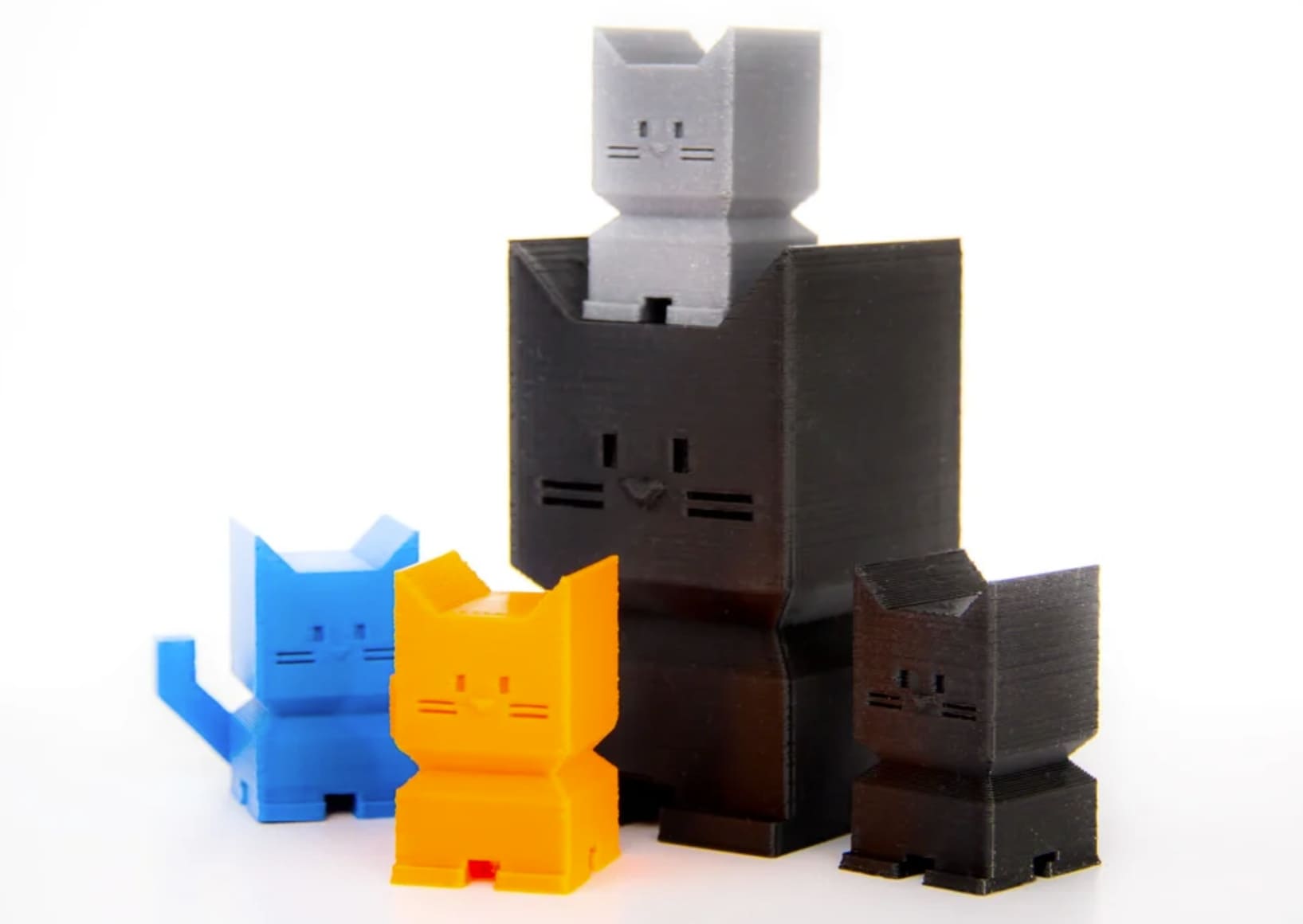

5. Cali-Cat

The Cali‑Cat calibration print is a compact feline figurine that measures approximately 20 × 20 mm at its body base, requiring under an hour and minimal filament to print, yet incorporates key diagnostic features such as planar surfaces for dimensional checks and vertical walls for overhang and bridging assessments. Its geometry deliberately includes slight overhangs, fine surface details, and sections that induce common print challenges—stringing, layer misregistration, and extrusion inconsistencies—so deviations directly reveal calibration and slicer‑parameter issues. Users even place two cats at different scales back‑to‑back to compare temperature and flow settings swiftly, exploiting the model’s consistent proportions for dual‑size calibration sessions.

Image Source: Dezign (Thingiverse)

6. Cali-Dragon

The Cali‑Dragon is a compact calibration model created to push FFF/FDM printers through common stress tests—surface smoothness (layer consistency), stringing, small perimeter accuracy, overhang handling, ghosting artifacts, and fine-detail reproduction—all in a single print. The model’s profile encourages multicolor printing—users often print “armies” of dragons simultaneously to compare filament batches or MMU configurations—highlighting its versatility for both single‑ and multi‑extrusion setups. Many enthusiasts favor Cali‑Dragon over the traditional Benchy for its ability to reveal ghosting and pressure‑advance issues more distinctly, making it a preferred go‑to for diagnosing complex motion tuning and extrusion dynamics.

Image Source: mcgybeer (MakerWorld)

7. Benchbin

The Benchbin is a 3D printing torture test created by Prusa Research to benchmark quality, speed, and waste across multi‑color printing workflows. Its compact build features color‑coded chambers, purge towers, and wipe zones that expose layer alignment, filament‑switch fidelity, and purge efficiency in both single‑ and multi‑extruder setups. The model’s geometry integrates overhang steps, bridge spans, fine‑text extrusion zones, and wall‑thickness ladders to diagnose cooling performance, retraction settings, and extrusion consistency in one comprehensive print.

Image Source: Prusa Research (Printables)

8. Shootout Collection

The Shootout Collection is a set of performance‑oriented test geometries, designed to evaluate metrics such as dimensional accuracy, bridging capabilities, overhang tolerance, negative space clearance, fine feature resolution, and resonance artifacts on printers. These models are engineered for rapid printing—most complete within 15–30 minutes—and use minimal filament, making them ideal for routine diagnostics and iterative calibration. By regularly printing Shootout models, users can catch drift in axis calibration, detect cooling inefficiencies, and verify slicer parameter stability before committing to complex or material‑intensive projects. Overall, the Shootout Collection offers a comprehensive, accessible, and community‑supported toolkit for maintaining consistent 3D printer performance.

Image Source: MAKE (Thingiverse)

9. Clearance Tolerance Test

The Clearance Tolerance Test is a purpose‑built STL designed to evaluate the minimum gap your FFF/FDM printer can reliably produce, helping you quantify clearance capabilities in under an hour of printing. The model includes a series of interlocking pin-hole pairs with nominal clearances of 0.35mm, 0.30mm, 0.25mm, 0.20mm, 0.15mm, and 0.10mm, allowing you to precisely determine the minimum printable tolerance for your specific hardware and consumables. This simplified test is ideal as a first step in material verification, routine maintenance, or post-production benchmarking to ensure your printer maintains optimal dimensional fidelity over the long term.

Image Source: 3DMakerNoob (Printables)

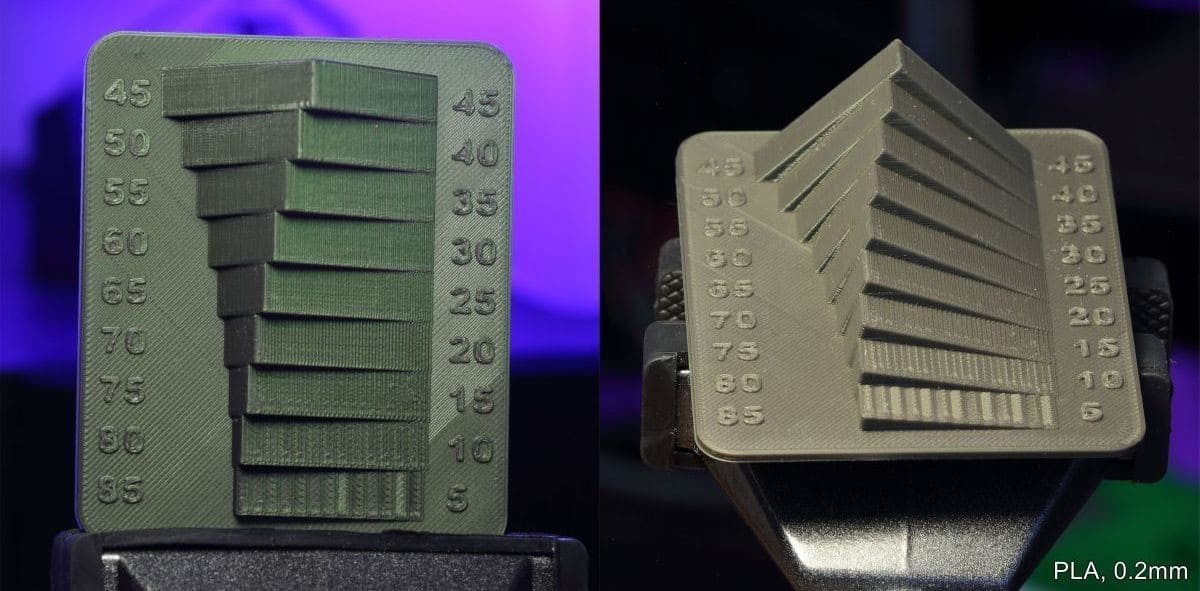

10. Slope Print Test

The Slope Print Test is a specialized calibration model featuring 18 precisely angled planes ranging from 5° to 85°, allowing users to evaluate unsupported printing limits in fine 5° increments. Designed for FFF/FDM machines without requiring supports, it quickly exposes the maximum overhang each printer can handle, highlighting cooling efficiency and slicer compensation needs. Its slim profile prints in under 15 minutes on most build plates, enabling rapid iteration across materials and layer heights. Its precision‑angled geometry offers more diagnostic depth than spherical or stepped tests, empowering users to optimize hardware mods like part‑cooling ducts and extrusion profiles.

Image Source: Devstroyer (Cults)