What are ULTEM (PEI) and Polycarbonate (PC)?

ULTEM (PEI)

ULTEM is a trade name most commonly associated with polyetherimide (PEI). It’s an amorphous, high-performance thermoplastic known for exceptional thermal stability, good mechanical strength, and intrinsic flame retardance. Because of those traits, ULTEM is widely used when parts must survive sustained high temperatures, aggressive sterilization procedures, or strict flame/halogen requirements. In additive manufacturing, ULTEM is considered an advanced material as it is capable of delivering near-engineering-grade performance when printed on the right equipment.

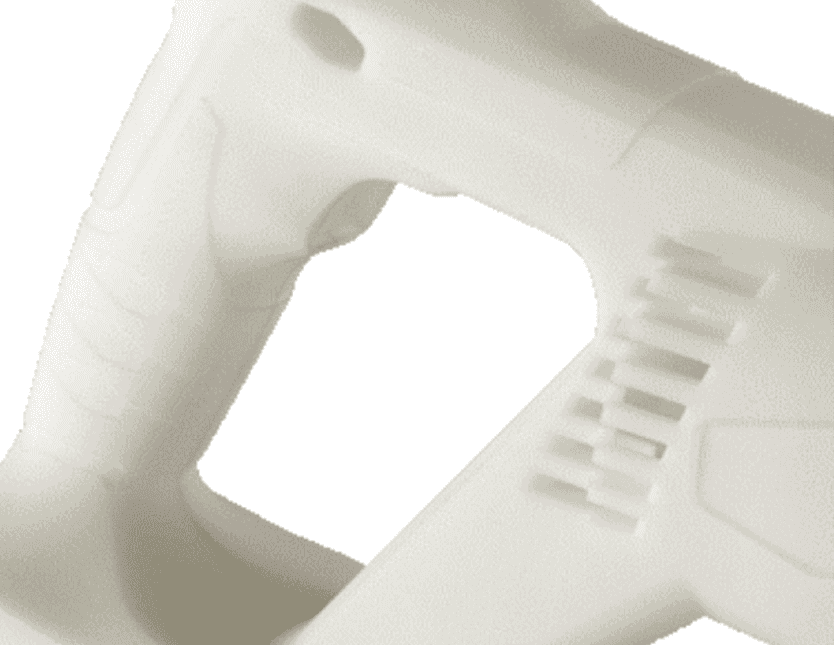

.png)

Image Source: Stratasys

Polycarbonate (PC)

Polycarbonate is a tough, impact-resistant engineering plastic used for everything from transparent glazing to rugged housings. PC combines high toughness and good heat resistance compared with commodity plastics, but it is more flexible and generally less heat-resistant than ULTEM. PC is favored when impact resistance, dimensional stability, and clarity (for some grades) matter.

.jpg)

Image Source: 3DSourced

Key Properties

|

Property |

ULTEM (PEI) |

Polycarbonate (PC) |

|

Heat resistance |

Very high, suited to elevated continuous service temperatures |

High, good short-term heat resistance but lower than ULTEM |

|

Stiffness & tensile strength |

High stiffness and strength |

Moderate to high stiffness, less stiff than ULTEM |

|

Impact resistance |

Good toughness but more brittle than PC in extreme impact |

Excellent impact resistance, one of PC’s key strengths |

|

Dimensional stability |

Excellent at temperature |

Good, but may creep more under long load/time |

|

Chemical resistance |

Good to many chemicals; some solvents can affect it |

Reasonable chemical resistance; certain solvents attack PC |

|

Flammability |

Many grades are self-extinguishing; good flame performance |

Generally less flame-resistant unless specially formulated |

|

Sterilization potential |

Often chosen for sterilizable medical fixtures (depends on grade) |

Some grades tolerate sterilization methods; check specific grade |

|

Print difficulty |

Difficult, requires industrial high-temperature hardware and controlled environment |

Moderately difficult, needs high temperatures, enclosure helpful |

|

Typical applications |

Aerospace, medical sterilizable parts, high-temp fixtures |

Housings, explosion-resistant covers, impact parts, prototypes |

Which 3D Printing Technologies Work Best

Both ULTEM and PC have been adopted primarily in filament-based (FDM/FFF) additive manufacturing for functional parts, but they behave differently on machines and require different levels of process control.

Fused Filament Fabrication (FDM / FFF)

ULTEM

Printing ULTEM reliably typically requires industrial FDM printers capable of very high nozzle temperatures and a heated, controlled chamber. A high-temperature hot end, a heated build plate, and an enclosed heated chamber that can maintain elevated ambient temperatures are essential to reduce warpage and achieve good interlayer adhesion. Many smaller desktop printers can’t handle ULTEM; it’s usually printed on specialized platforms.

Polycarbonate

PC is printable on high-end desktop or industrial FDM machines. It still requires higher nozzle temperatures and a heated bed (and preferably an enclosure) to prevent warping and cracking. Some PC blends or modified PC filaments are designed to be easier to print on prosumer machines.

Selective Laser Sintering (SLS) / Powder Beds

ULTEM and standard PC are not commonly available in SLS powders for general production; these processes more often use nylon (PA) powders or specialized high-performance powders. There are, however, industry specialties and composite powders for certain high-performance needs, but they are niche.

Other Methods (SLA / DLP / MJF, etc.)

SLA/DLP resins and HP’s MJF ecosystems have engineering resins/powders that mimic some properties of PC and PEI, but they are not the same as printing genuine ULTEM or PC polymer parts. For true material performance of ULTEM or PC, high-temperature FDM is the common route.

Industries and Applications

ULTEM‘s Typical Industries

• Aerospace: high-temperature ducting, brackets and lightweight fixtures where flame retardance and thermal stability matter.

• Medical & dental: sterilizable jigs, surgical guides, fixtures; selected grades are used where repeated sterilization is required.

• Electronics: insulators, connector housings and components requiring dimensional stability at elevated temperatures.

• Automotive & industrial: small-run high-temperature components and tooling.

Polycarbonate's Typical Industries

• Consumer & industrial housings: protective covers, instrument enclosures, and ruggedized parts that must survive drops and impacts.

• Prototyping functional parts: where toughness and realistic mechanical feedback are important.

• Lighting & glazing (transparent grades): for small transparent components in prototypes or low-volume parts (note: optical quality varies when 3D printed).

• Automotive: interior components, clips, and parts that balance toughness and cost.

Cost and Manufacturability

Material Cost

ULTEM is a specialty engineering polymer and is priced accordingly. It's typically more expensive than PC material. Polycarbonate filaments are more cost-competitive and more widely stocked by filament suppliers.

Machine and Processing Cost

ULTEM usually requires industrial, high-temperature 3D printers. That ups the per-part cost because of machine depreciation, controlled environments, and often slower build strategies to ensure reliability. PC can often be printed on higher-end prosumer machines, lowering the entry cost.

Post-processing and Finishing

Both materials accept secondary operations (machining, tapping, solvent or adhesive bonding with compatible agents), but ULTEM’s high heat resistance and flame performance can make some finishing methods different or more limited. PC is easier to bond and machine in many cases.

Scale and Transfer to Production

If a part moves from prototyping to low-volume production, consider whether injection molding or other manufacturing routes are more economical. PC scales well into molded parts; ULTEM can be molded, but tooling costs and material behavior should be evaluated.

Supply Chain and Lead Times

PC is ubiquitous and generally easy to source. ULTEM grades and specialty blends can have longer lead times and sometimes minimum order requirements, especially for certified grades used in regulated industries.

Decision Checklist

1. What is the maximum continuous temperature your part must tolerate?

If it’s very high (sustained elevated temperatures), prefer ULTEM. If moderate, PC is likely sufficient.

2. Does the part need to withstand repeated sterilization or strict fire/flame standards?

ULTEM is commonly chosen for sterilizable/flammability-sensitive uses; verify the specific grade and certification.

3. Is impact resistance or toughness the highest priority?

Choose PC for superior impact performance.

4. What printing equipment do you have access to?

If you only have prosumer printers, PC (or modified PC blends) is more likely to be achievable. For ULTEM, you’ll usually need industrial high-temp hardware.

5. What’s your budget for material and per-part cost?

If the budget is tight and ULTEM’s high-temp benefits aren’t necessary, PC delivers strong performance at a lower cost.

6. Is certification or traceability required (e.g., aerospace, medical)?

ULTEM may be available in certified grades; check lot traceability and supplier documentation.

7. Do you need optical clarity?

PC has transparent grades; 3D printed clarity is limited but possible for small, carefully printed parts, and ULTEM is opaque.

8. Is post-processing or secondary machining needed?

Both materials can be finished, but confirm the compatibility of adhesives, paints, and machining parameters for the chosen grade.

COMMENTS

- Be the first to share your thoughts!