Faster, Easier, and Cheaper

The innovation of 3D printing, or additive manufacturing, to manufacture NASCAR’s Next Gen cars has made a paradigm shift in how teams conceive, test, and create parts. Unlike traditional subtractive methods like CNC machining that carve parts from solid blocks, 3D printing builds parts layer upon layer, providing for intricate geometries and rapid iteration. This has cut through production time like butter: teams, for instance, Joe Gibbs Racing (JGR), can print track-specific parts overnight so that the engineers can test aerodynamic tweaks during limited practice sessions.

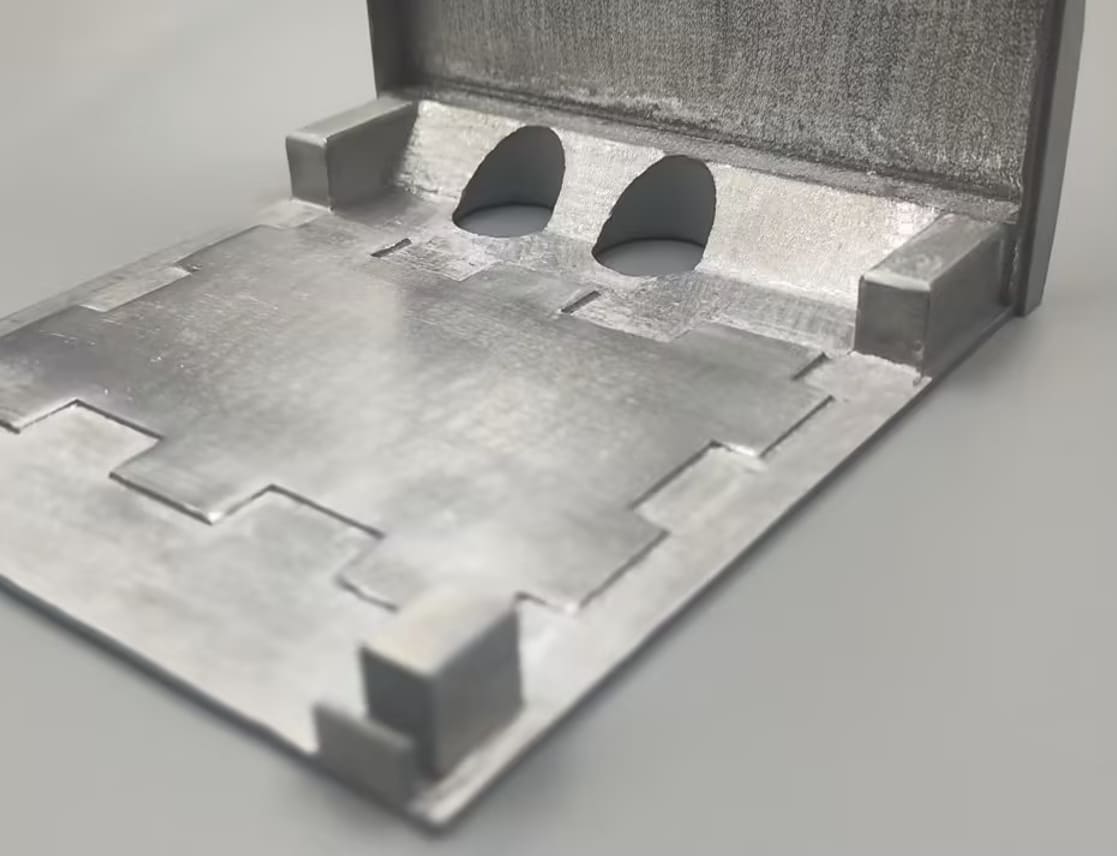

Cost savings are another fundamental motivator. Stratasys, a 3D printing partner of NASCAR, notes that additive manufacturing reduces reliance on skilled labor and expensive CNC programming while minimizing material waste. For instance, when JGR had a misaligned tube, the shop built a custom fixture in a matter of hours through 3D printing instead of machining, which had taken days prior. Recent advancements in materials-including heat-resistant thermoplastics like ULTEM 9085 and carbon-fiber-reinforced nylon (Nylon 12CF)-have augmented toughness and performance while keeping costs from spiraling upward.

Image Source: Motorsports Tribune

3D Printed Parts Used in NASCAR Cars

NASCAR teams leverage 3D printing to optimize both performance and reliability through custom components:

Aerodynamic Ducts: Pass-thru ducts channel air to cool brakes and transaxles while subtly manipulating downforce. JGR engineers printed multiple versions with varying bends and widths to fine-tune airflow.

Brake Cooling Systems: Front bumper brake ducts, now restricted at certain tracks due to their aerodynamic advantages, were initially printed in carbon fiber or polymers for track-specific cooling efficiency.

Windshield Ventilation Units: Stratasys-produced PA11 vents ensure driver comfort by directing cool air into cockpits. Over 37,000 miles of testing validate their reliability.

Custom Brackets and Fixtures: Flexible TPU clamps hold body panels in precise positions during assembly, optimizing aerodynamics.

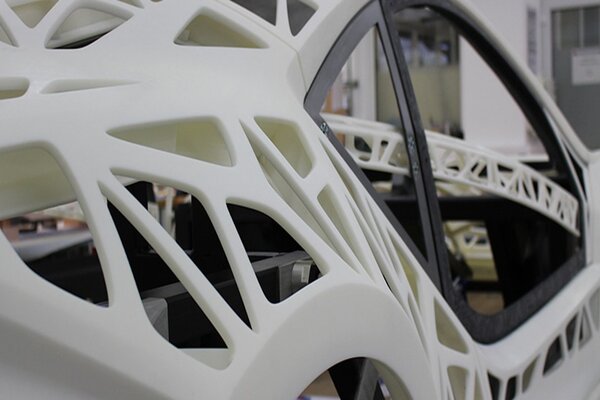

Prototyping and Tooling: Teams rapidly prototype parts like side mirrors or gear cooling ducts, testing designs in wind tunnels before final production.

Chevrolet’s motorsports division highlights broader applications, using 3D-printed oil tanks, hydration systems, and damper shields in Corvette, INDYCAR, and Silverado race trucks. These parts demonstrate additive manufacturing’s versatility, balancing strength, weight reduction, and cost efficiency.

Image Source: Stratasys

Our Capabilities to Help the Automotive Industry

3DSPRO has successfully partnered with many automotive clients, delivering innovative solutions tailored to their unique needs. Here are our capabilities to help you accelerate your project's progress:

Comprehensive 3D Printing Services

We offer a wide range of 3D printing services, including SLM (Selective Laser Melting), SLA (Stereolithography), DLP (Digital Light Processing), SLS (Selective Laser Sintering), and MJF (Multi Jet Fusion). These advanced techniques ensure precision and quality in every print, allowing us to meet your exact specifications.

Diverse Material Choices

We offer an extensive range of materials, including high-performance plastics, metals, and composites. Whether you need lightweight solutions for improved fuel efficiency or robust materials for enhanced durability, our material options cater to all your requirements.

Custom Post-Processing Solutions

Our custom post-processing solutions, covering color, finishes, and function, such as spray painting, bead blasting, anodizing, polishing, tapping, etc., ensure that your parts not only meet functional requirements but also achieve the desired aesthetic appeal. We work closely with you to deliver the perfect finish for your components.

Design Freedom

Complex geometries, such as integrated air channels in brake pedals or lightweight headlight assemblies, are now feasible, accelerating R&D cycles. Our advanced 3D printing capabilities enable the creation of intricate designs that were previously unattainable.

On-Demand Manufacturing

Our on-demand manufacturing services allow automakers to decentralize production, reducing inventory costs and enabling rapid response to design changes. This flexibility is a critical advantage in competitive markets, allowing you to stay ahead of the curve.

COMMENTS

- Be the first to share your thoughts!