What are carbon fiber materials in 3d printing?

Carbon fiber materials in 3D printing refer to filaments or powders that incorporate carbon fibers into a standard plastic base material, enhancing its properties and performance. 3D printable carbon fibers are known for exceptional strength-to-weight ratio and are commonly used in high-performance applications.

Composition of Carbon Fiber Filaments

The carbon fibers used in 3D printing are typically short strands, known as chopped fibers, which are small enough to pass through the printer’s nozzle. They are mixed with thermoplastics like PLA, ABS, PETG, Nylon, or Polycarbonate.

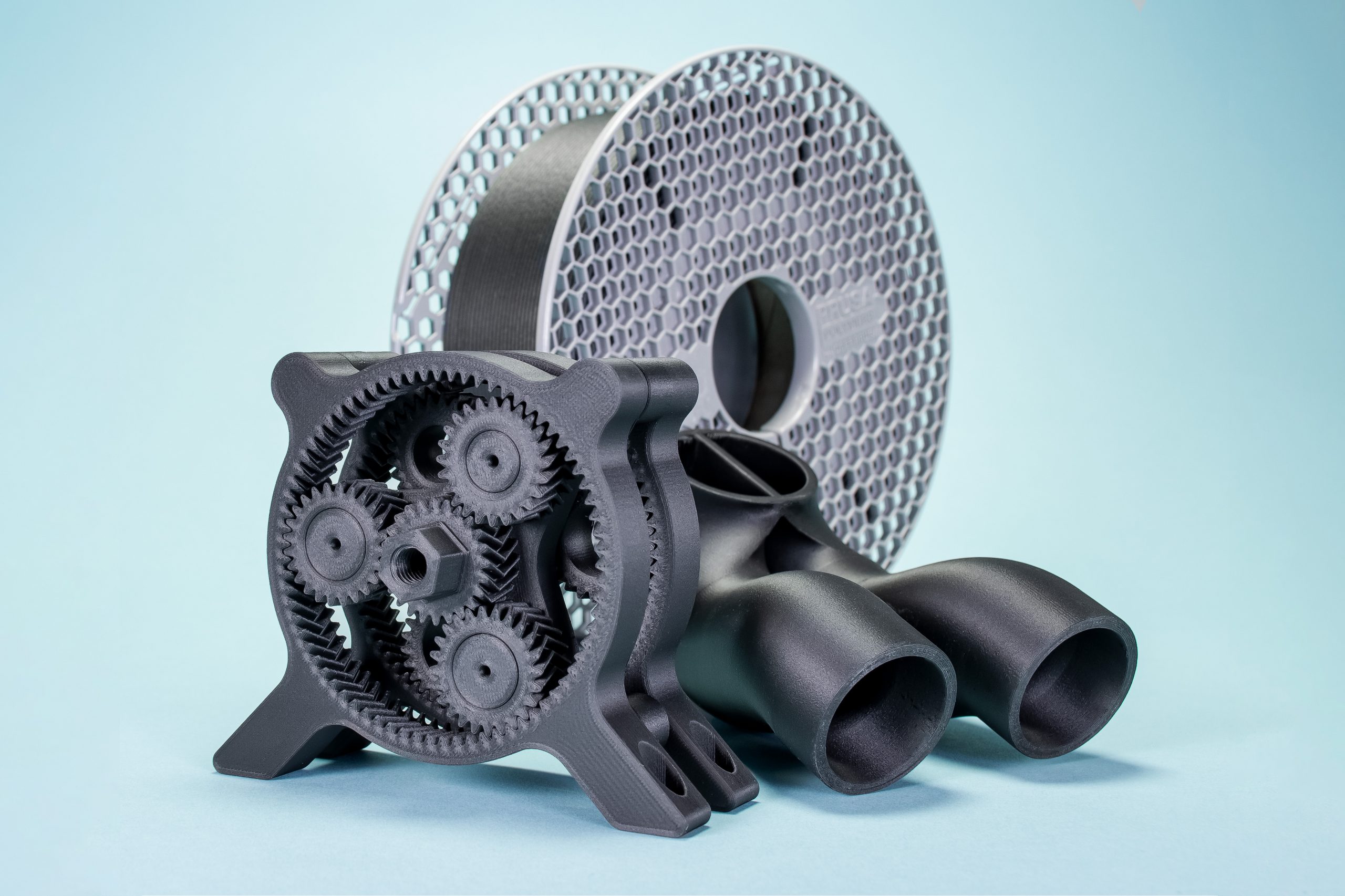

3D Printable Carbon Fiber Plastic Powders

In addition to carbon fiber filaments, there are also 3D printable carbon fiber plastic powders, which are particularly used in Selective Laser Sintering (SLS) processes. These powders typically consist of a nylon base material reinforced with carbon fibers.

Image Source: Prusament PA11 (Nylon) Carbon Fiber Black

Types of 3D Printing Carbon Fiber Materials

1. Carbon Fiber Filaments

These are the most common carbon fiber materials used in Fused Deposition Modeling (FDM) 3D printers. The filaments are a blend of carbon fibers and standard plastic materials such as PLA, ABS, PETG, Nylon, or Polycarbonate. The carbon fibers are typically short, chopped strands that are mixed with the plastic to create a composite filament.

2. Continuous Carbon Fiber Filaments

Unlike chopped carbon fiber filaments, continuous carbon fiber filaments involve embedding a continuous strand of carbon fiber into a base thermoplastic material. This type of filament requires specialized 3D printers with dual extruders: one for the thermoplastic and one for the carbon fiber. Parts made with continuous carbon fiber are exceptionally strong and are often used in professional and industrial applications.

3. Carbon Fiber Reinforced Powders

For Selective Laser Sintering (SLS), carbon fiber materials are available in the form of reinforced powders, typically nylon-based. These powders contain short carbon fibers that provide enhanced strength and stiffness to the printed parts. SLS technology allows for complex geometries and fine details.

Image Source: Dynamism

Carbon Fiber 3D Printing Processes

Fused Deposition Modeling (FDM)

FDM is the most widely used 3D printing process for carbon fiber materials. It works by melting carbon fiber-infused filament and extruding it through a steel-hardened nozzle, layer by layer, to build the part. FDM is favored for its simplicity, cost-effectiveness, and compatibility with a variety of carbon fiber composite filaments. It’s ideal for prototyping, custom tooling, and end-use parts in industries like automotive and aerospace.

Continuous Filament Fabrication (CFF)

CFF is a variation of FDM that specifically uses continuous carbon fiber strands in addition to a base thermoplastic filament. This process requires a dual-nozzle system: one for the thermoplastic and one for the continuous carbon fiber. CFF produces parts with superior strength and stiffness compared to traditional FDM, making it suitable for high-load applications and functional components.

Selective Laser Sintering (SLS)

SLS uses a laser to sinter carbon fiber-reinforced nylon powders, layer by layer, to create a solid part. This process allows for the production of complex geometries with high precision and excellent mechanical properties. SLS is commonly used for small to medium-batch production of functional parts that require high strength and durability.

Stereolithography (SLA)

While less common for carbon fiber printing, SLA can be used with carbon fiber-filled resins. The process involves curing liquid resin layer by layer with a UV laser. SLA is known for producing parts with a smooth surface finish and high detail. However, the mechanical properties of carbon fiber parts produced with SLA may not be as strong as those made with FDM or CFF.

Carbon Fiber 3D Printers

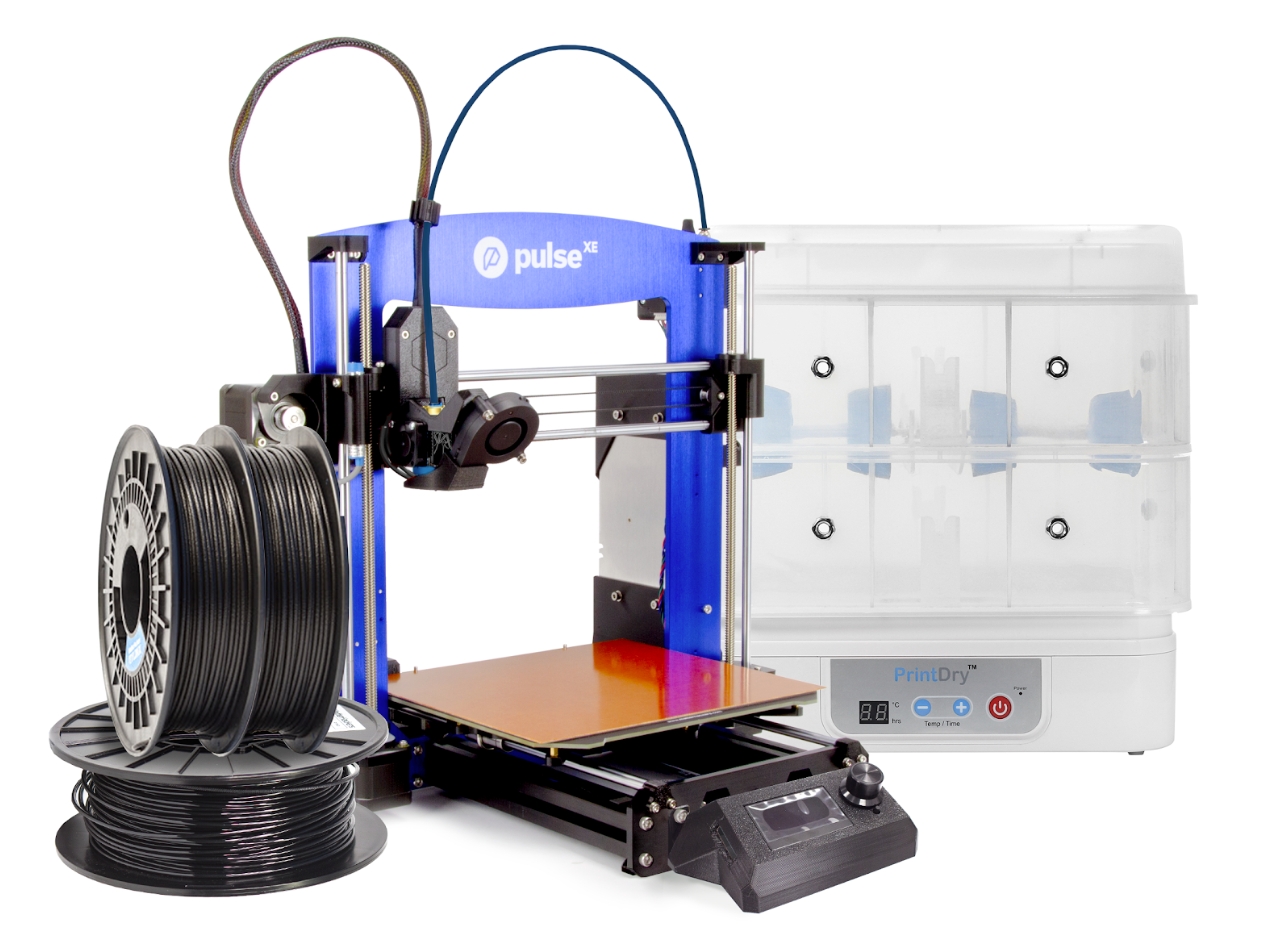

1. Pulse XE

The Pulse XE is an affordable option for those looking to print with carbon fiber materials. It’s designed to print Matterhackers’ NylonX filament, which is a mix of nylon with carbon fibers. The printer features a Bondtech BMG extruder and E3D V6 hot end and offers upgrades such as a hardened steel nozzle or ruby-tipped nozzle for enhanced performance.

Image Source: MatterHackers

2. Raise3D E2

The Raise3D E2 is an enclosed 3D printer that features IDEX technologies with Mirror and Duplication modes for efficient dual extrusion printing. It’s capable of large-scale 3D printing and high-quality prototyping, making it a versatile choice for professional environments.

Image Source: Raise 3D

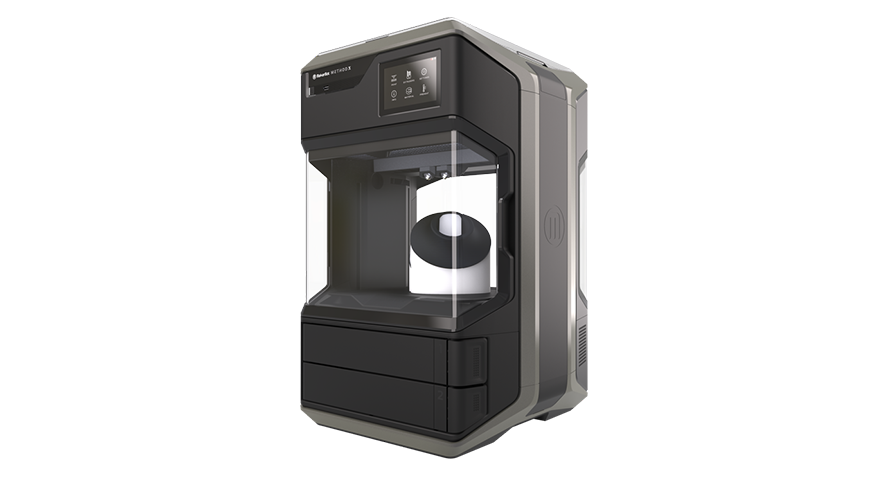

3. MakerBot METHOD X Carbon Fiber Edition

This printer is specifically designed for carbon fiber 3D printing and offers a robust build volume and high-quality prints. It’s a great choice for those requiring precision and reliability in their carbon fiber parts.

Image Source: MakerBot

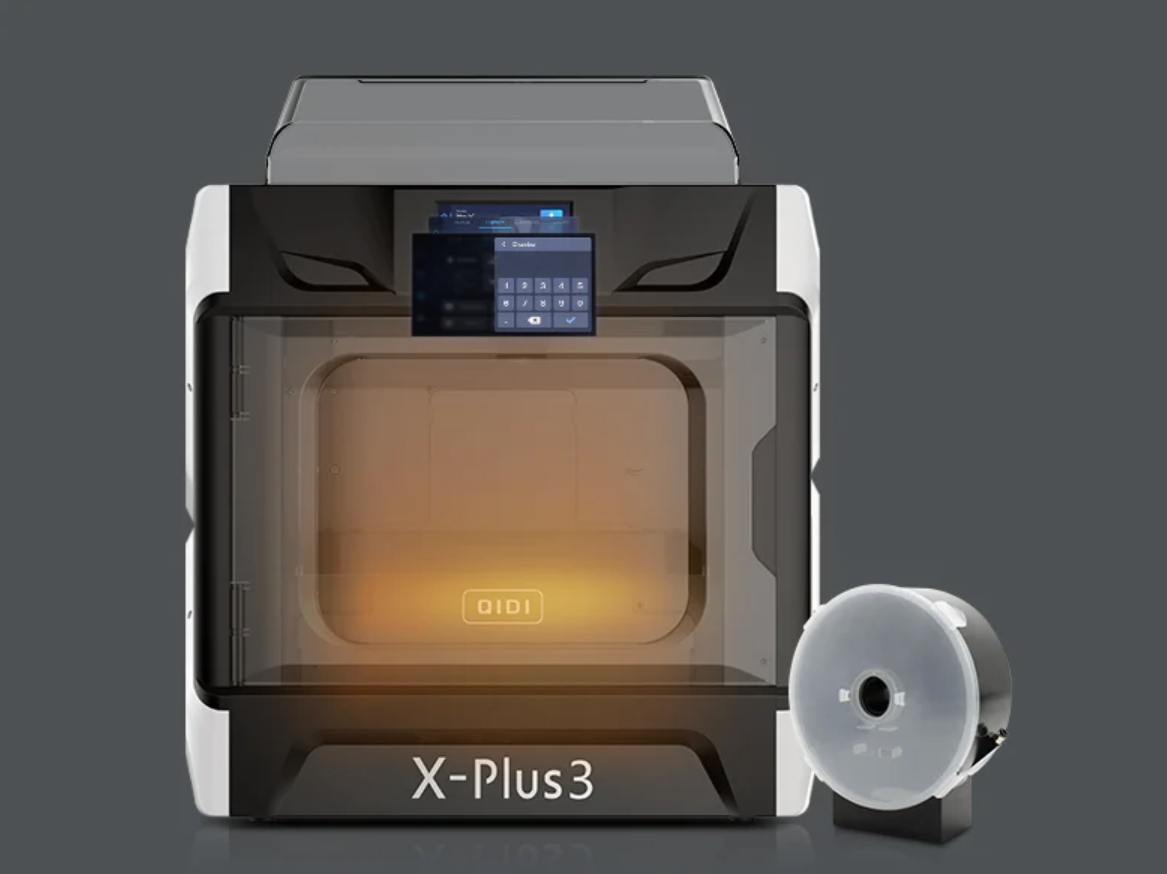

4. Qidi Tech X-Plus

For those on a budget, the Qidi Tech X-Plus is an excellent option. It’s known for its reliability and ability to print a variety of materials, including carbon fiber composites.

Image Source: Qidi

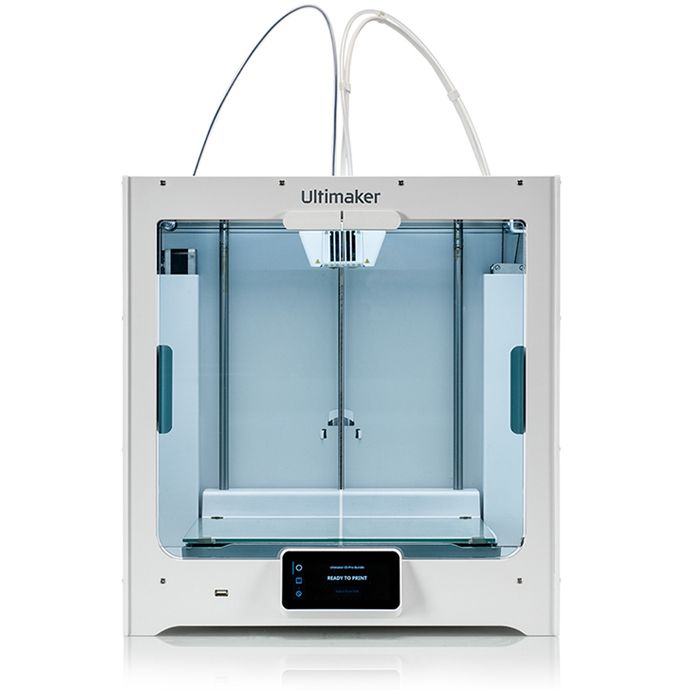

5. Ultimaker S5

The Ultimaker S5 is a premium 3D printer that offers dual extrusion capabilities and a large build volume. It’s suitable for printing with high-strength materials like carbon fiber and is ideal for industrial applications.

Image Source: Ultimaker

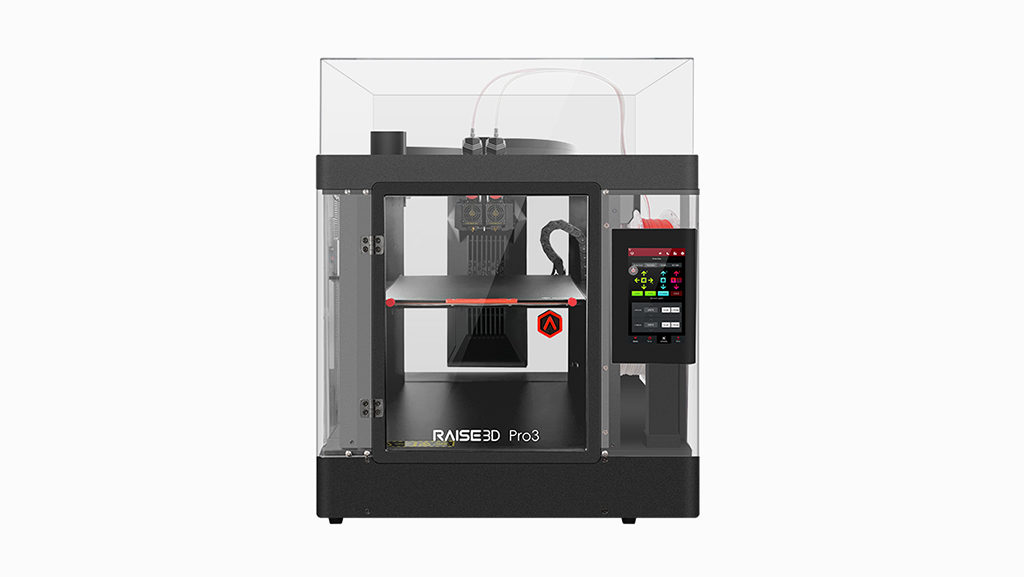

6. Raise3D Pro3

The Raise3D Pro3 is known for its reliability and is another excellent choice for printing with carbon fiber materials. It offers a large build volume and high-quality prints, suitable for professional and industrial use.

Image Source: Raise3D

Benefits of Carbon Fiber 3D Printing

1. Enhanced Mechanical Properties

3D-printed carbon fiber parts exhibit superior mechanical properties, including increased stiffness and durability. They are suitable for high-performance parts that need to withstand significant stress and strain.

2. Excellent Dimensional Stability

Carbon fiber materials do not shrink when cooling, which results in parts with excellent dimensional stability. It is highly suitable for applications that require precise tolerances and fit.

3. Heat Resistance

Carbon fiber can withstand high temperatures without melting, making it suitable for components that will be exposed to heat during their service life.

4. Lower Production Costs

For low-volume production, 3D printing with carbon fiber is often more cost-effective than traditional manufacturing methods. It eliminates the need for expensive molds and reduces labor costs associated with fabrication.

5. Faster Turnaround Times

The ability to go directly from design to production without the need for tooling allows for rapid prototyping and faster production cycles.

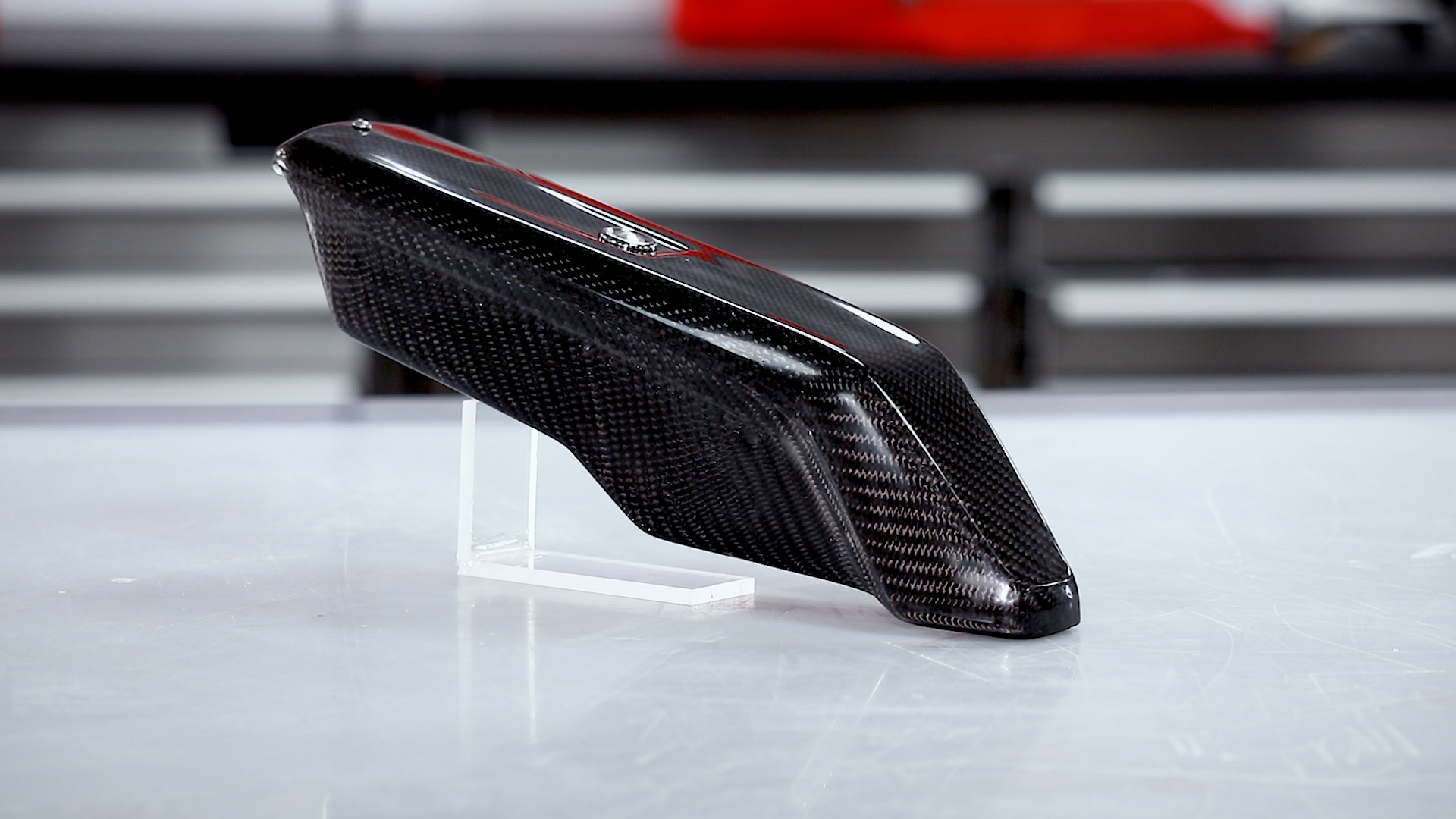

3D Printed Carbon Fiber Applications

- Aerospace: 3D printed carbon fiber is extensively used in the aerospace industry for manufacturing lightweight and strong components such as, drones, satellite components, and aircraft parts.

- Automotive: 3D printed carbon fiber is utilized to produce lightweight parts, functional prototypes and custom parts for high-performance and luxury vehicles.

- Sports Equipment: Carbon fiber’s strength and light weight make it ideal for sports equipment, including bicycles, protective gear and rackets and clubs.

- Medical Devices: In the medical field, 3D printed carbon fiber is used for prosthetics, orthopedic implants and surgical tools.

- Consumer Goods: 3D printed carbon fiber is also making its way into consumer products such as gadgets, decorative pieces, and wearables.

Image Source: Carbon 3D

COMMENTS

- Be the first to share your thoughts!