What is polypropylene?

Polypropylene (PP), also known as polypropene, is a versatile thermoplastic polymer produced through the polymerization of propylene. It is characterized by its linear hydrocarbon structure, resulting in a material that is partially crystalline and non-polar. With a high melting point ranging from 130 to 171°C, low density (0.895 to 0.93 g/cm³), and excellent chemical resistance, polypropylene is highly valued for its toughness and durability.

Developed in the early 1950s by chemists Karl Rehn and Giulio Natta, polypropylene has become the second-most widely produced plastic globally. Its applications span various industries, including packaging, automotive, textiles, and medical devices.

Polypropylene in 3D Printing

Known for its chemical resistance, flexibility, and durability, PP is a popular material for various 3D printing applications. However, its semi-crystalline nature presents challenges, such as warping during the cooling process, which requires precise temperature control throughout printing.

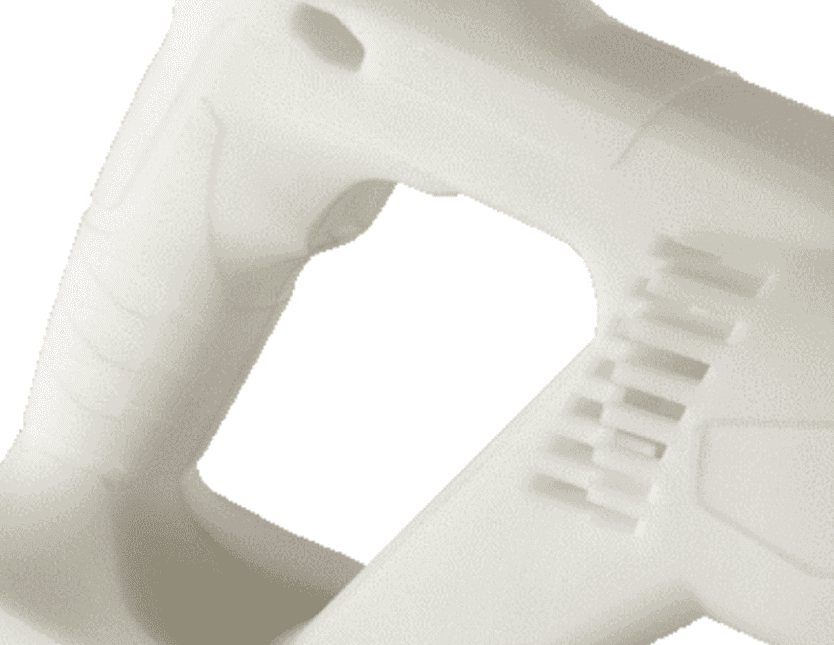

In 3D printing, polypropylene is primarily used in Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) technologies. FDM printing with PP involves extruding the material through a heated nozzle, while SLS uses a laser to sinter powdered PP. Both methods leverage PP’s lightweight and fatigue-resistant properties, making it suitable for producing functional prototypes, automotive parts, and consumer goods.

Image Source: PPprint

Mechanical Properties of 3D Printed Polypropylene

Key Mechanical Properties

1. Tensile Strength

● Moderate tensile strength, typically ranging from 20 to 40 MPa.

● Varies depending on printing parameters and specific PP formulation.

● Generally lower than ABS or PLA but higher than flexible filaments.

2. Elongation at Break

● High elongation at break, often between 100% to 600%.

● Provides good ductility and impact resistance.

● Allows for flexible and durable parts.

3. Flexural Modulus

● Relatively low flexural modulus, usually between 1.0 to 1.5 GPa.

● Results in parts with good flexibility and resistance to fatigue.

4. Impact Strength

● Excellent impact strength, especially at room temperature.

● Notched Izod impact strength typically ranges from 20 to 100 J/m.

● Contributes to the material's durability and toughness.

5. Hardness

● Shore D hardness is typically between 60 to 70.

● Provides a good balance between surface durability and flexibility.

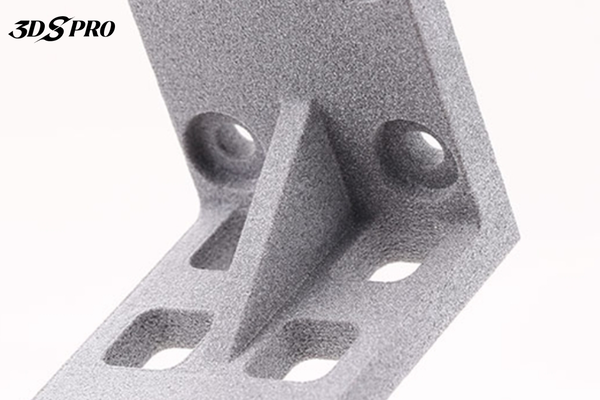

Image Source: BASF

Polypropylene 3D Printing Methods

Fused Deposition Modeling (FDM)

FDM is the most common method for 3D printing polypropylene due to its accessibility and cost-effectiveness.

Key Aspects:

● Utilizes PP filaments.

● Requires heated build plate (typically 60-80°C) for proper adhesion.

● Print temperatures usually range from 220-250°C.

● Often needs an enclosed printing environment to prevent warping.

Challenges:

● Warping and shrinkage due to PP's semi-crystalline nature.

● Poor layer adhesion compared to other thermoplastics.

● Difficulty in first-layer adhesion to the build plate.

Solutions:

● Use of PP-specific build plates or adhesion solutions.

● Optimized cooling strategies to control crystallization.

● Careful control of print parameters to enhance layer bonding.

Selective Laser Sintering (SLS)

SLS offers the ability to create complex geometries with PP powder.

Key Aspects:

● Uses fine PP powder as the printing material.

● Laser sinters the powder layer by layer.

● No need for support structures due to the powder bed.

Advantages:

● High-resolution and complex geometries are possible.

● Good mechanical properties due to uniform sintering.

● Suitable for functional prototypes and end-use parts.

Challenges:

● Requires specialized, expensive equipment.

● Post-processing is needed to improve the surface finish.

Material Extrusion with Pellets

A newer method that uses PP pellets instead of filaments for larger-scale printing.

Key Aspects:

● Utilizes PP pellets fed directly into a screw extruder.

● Suitable for large-format 3D printing.

● Often used in industrial settings.

Advantages:

Cost-effective for large parts due to cheaper pellet material.

Allows for custom material blends and additives.

Higher throughput compared to filament-based FDM.

Challenges:

Requires specialized equipment.

Less precise than filament-based methods for small details.

Multi Jet Fusion (MJF)

While primarily used with nylon, some manufacturers have developed PP materials for MJF.

Key Aspects:

● Uses PP powder with binding and detailing agents.

● Parts are built layer by layer and then fused with heat.

Advantages:

● High productivity and scalability.

● Good mechanical properties and surface finish.

● Suitable for functional prototypes and end-use parts.

Challenges:

● Limited material options compared to other PP printing methods.

● Requires specialized, expensive equipment.

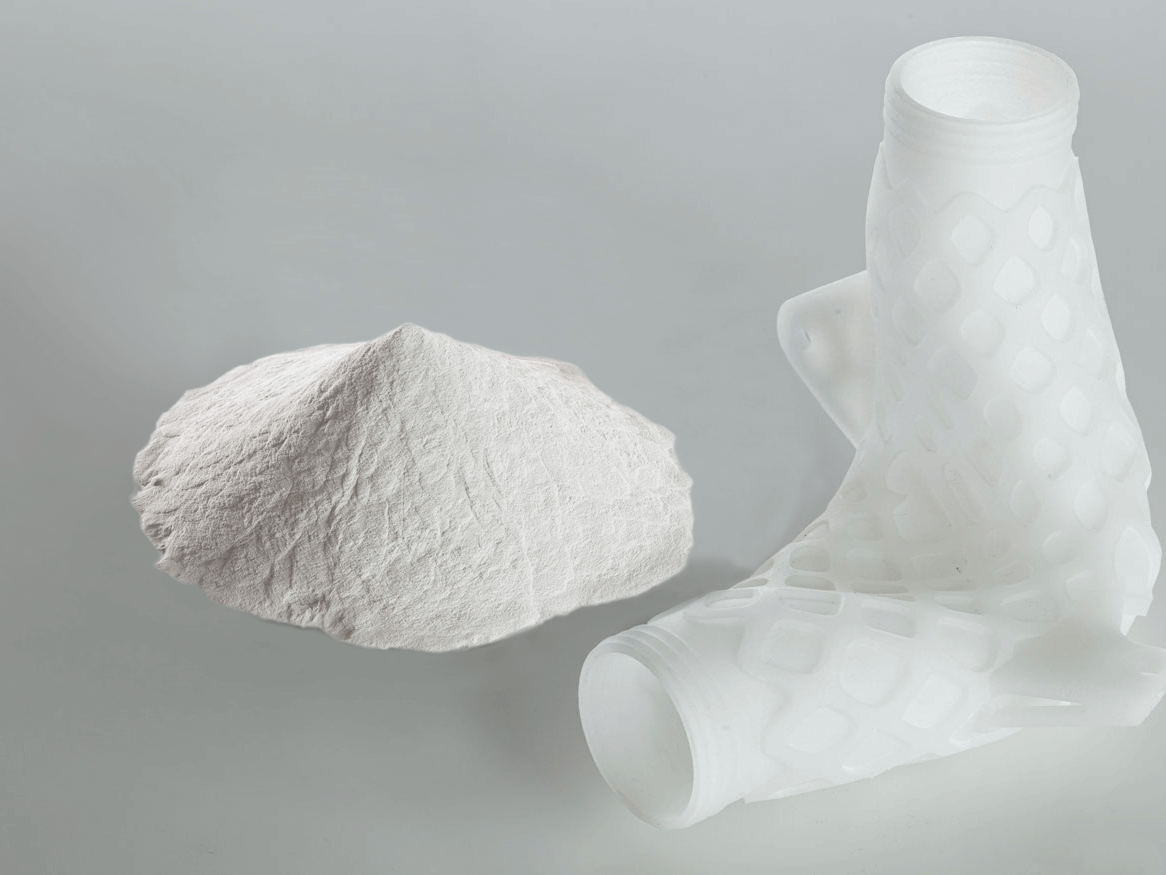

Image Source: Formlabs

Pros and Cons of 3D Printing Polypropylene Material

Pros

1. Chemical Resistance: Polypropylene is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it suitable for applications in harsh environments.

2. Flexibility and Toughness: PP is known for its excellent flexibility and toughness, allowing it to withstand significant mechanical stress without breaking. PP material is ideal for producing durable parts such as living hinges and straps.

3. Low Density: With a low density, PP is lightweight, which is beneficial for applications where weight reduction is crucial.

4. Fatigue Resistance: Polypropylene exhibits good fatigue resistance, maintaining its mechanical properties under cyclic loading conditions.

5. Smooth Surface Finish: 3D-printed PP parts often have a smooth surface finish, which can be advantageous for aesthetic and functional purposes.

Cons

1. Warping and Shrinkage: One of the main challenges of 3D printing with PP is its tendency to warp and shrink during the cooling process, which can affect the dimensional accuracy and surface finish of printed parts.

2. Adhesion Issues: PP has poor adhesion to the print bed and other surfaces, which can lead to print failures if not properly managed. Specialized adhesives or print bed treatments are often required.

3. High Printing Temperature: Polypropylene requires a high printing temperature, which can limit its compatibility with some 3D printers.

4. Cost: PP filament can be more expensive compared to other common 3D printing materials like PLA and ABS.

5. UV Sensitivity: Polypropylene is sensitive to ultraviolet light and oxidation, making it unsuitable for prolonged outdoor use.

Applications of 3D Printed Polypropylene

Automotive

Polypropylene is widely used in the automotive industry for creating functional prototypes, interior components, and custom parts. Its toughness and fatigue resistance make it ideal for parts that need to endure mechanical stress.

Packaging

The lightweight and durable nature of PP makes it perfect for designing packaging solutions. It is commonly used to produce containers, bottles, and packaging films that require chemical resistance and flexibility.

Medical

In the medical field, 3D-printed PP is used to produce surgical instruments, prosthetics, and medical devices. Its biocompatibility and chemical resistance are crucial for applications that demand sterility and durability.

Consumer Goods

Polypropylene is used to manufacture a variety of consumer products, including household items, toys, and sports equipment. Its ability to withstand wear and tear makes it suitable for everyday use.

Image Source: PPprint

Try 3D Printing PP Plastic Parts at 3DSPRO

If you’re looking to explore the benefits of 3D printing with polypropylene (PP), 3DSPRO offers advanced Selective Laser Sintering (SLS) 3D printing services tailored to your needs.

3DSPRO’s SLS 3D printing services with PP materials are ideal for producing complex geometries and functional prototypes that require the unique properties of polypropylene, such as chemical resistance, flexibility, and toughness. Whether you need custom automotive components, medical devices, or consumer goods, 3DSPRO can deliver high-quality results with precise accuracy and excellent surface finish.

COMMENTS

- Be the first to share your thoughts!