FDM is the most common and widely used 3D printing technology for everyday makers and consumers. It is suitable for rapid prototyping, functional testing, and low-volume production of plastic parts. FDM can print with a variety of thermoplastic materials, such as ABS, PLA, PETG, and nylon, that have different properties and applications.

What is fused deposition modeling (FDM 3D Printing)?

Fused deposition modeling (FDM) is a 3D printing technology that creates parts from the plastic filament by melting and then depositing them in layers. [1]

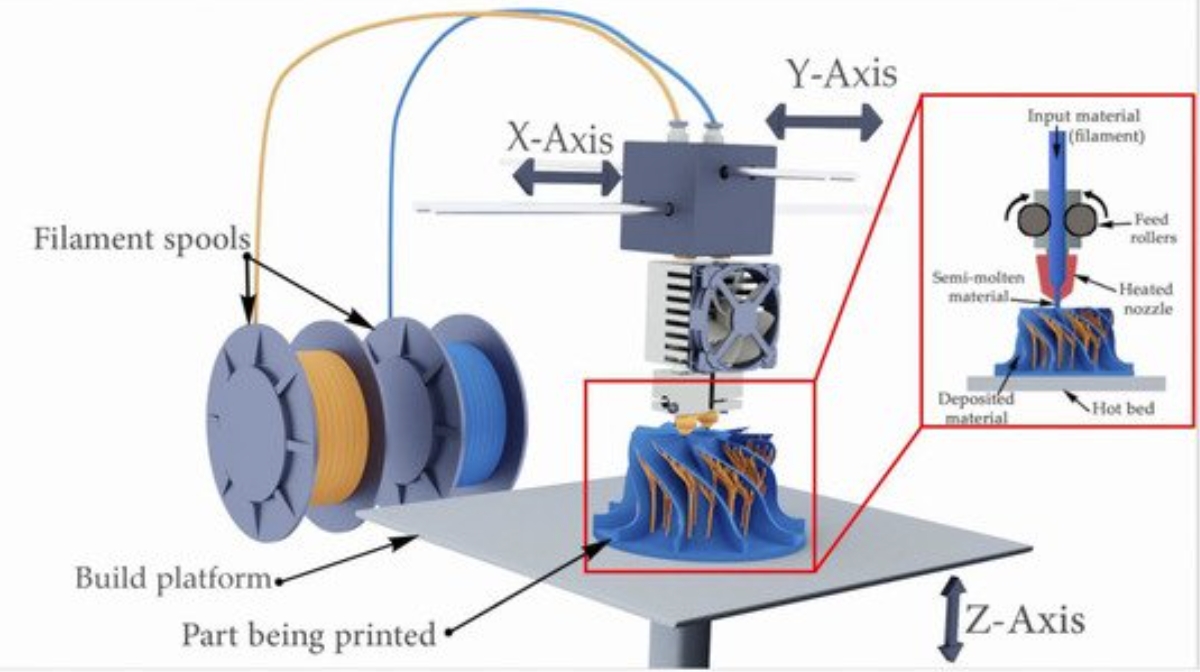

FDM works by feeding a spool of filament material through a heated extruder nozzle, which melts the material and extrudes it onto a build platform. The nozzle moves along the X and Y axes, following a predetermined path based on the digital design file. The build platform moves along the Z axis, lowering after each layer is completed. The process repeats until the entire part is formed.

Image Source: Stratasys

FDM 3D Printing Materials

FDM 3D printing materials are the filaments that are fed into the extruder nozzle and melted to form the layers of the printed part. There are many types of FDM filaments, each with different properties and applications.

PLA (Polylactic Acid)

PLA is a biodegradable and eco-friendly material made from cornstarch or sugarcane. It is the most popular and easy-to-use FDM filament, as it has a low printing temperature, good layer adhesion, and minimal warping. PLA is suitable for prototyping, decorative models, and low-stress parts. PLA comes in a wide range of colors and blends, such as glow-in-the-dark, transparent, or conductive PLA. However, it is not very durable, heat-resistant, or flexible and may degrade over time when exposed to moisture or sunlight.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and tough material widely used in the plastic industry. It has high impact, heat, and chemical resistance, making it ideal for functional parts such as gears, housings, or enclosures. ABS can also be post-processed by sanding, smoothing, or painting. However, ABS requires a heated bed and a well-ventilated environment to print, as it tends to warp and shrink when cooled and emits unpleasant fumes when heated.

PET (Polyethylene Terephthalate)

PET is a thermoplastic polymer that is commonly used for plastic bottles and food containers. PET is recyclable, transparent, and food-safe. PET can also be modified to create PETG (Polyethylene Terephthalate Glycol), which is more flexible, durable, and easier to print than PET. PET and PETG are suitable for printing parts that need to withstand water, heat, or chemicals, such as vases, bottles, or outdoor models. PET and PETG have good layer adhesion and minimal warping but may require higher printing temperatures and slower speeds than PLA or ABS.

Nylon (Polyamide)

Nylon is a synthetic polymer that is known for its strength, flexibility, and abrasion resistance. Nylon can be used to print parts that need to withstand high stress, wear, or impact, such as hinges, gears, or bearings. Nylon can also be dyed or blended with other materials, such as carbon fiber or glass fiber, to enhance its properties. However, Nylon is hygroscopic, meaning it absorbs moisture from the air, which can affect its print quality and performance. Nylon also requires high printing temperature and a heated bed to print and may warp or shrink when cooled.

TPU (Thermoplastic Polyurethane)

TPU is a type of flexible filament that can bend, stretch, and compress without breaking. It can be used to print elastic parts, such as gaskets, seals, or phone cases. TPU has good abrasion resistance, chemical resistance, and shock absorption. However, it is more difficult to print than rigid filaments, as it may jam or clog the extruder nozzle or curl or warp on the build platform. TPU also requires lower printing speed and higher printing temperature than PLA or ABS.

PC (Polycarbonate)

PC is a high-performance material that has excellent mechanical, thermal, and optical properties. PC is one of the strongest and most heat-resistant FDM filaments, as it can withstand temperatures up to 110°C and impacts up to 250 times greater than glass. PC can be used to print parts that need to endure high stress, heat, or light, such as automotive parts, medical devices, or lenses. However, PC is very challenging to print, as it requires a very high printing temperature, a heated bed, a heated chamber, and good ventilation to prevent warping, cracking, or fuming.

These are some of the most common FDM 3D printing materials. Still, many more options are available in the market, such as wood, metal, or ceramic filaments, which can offer different aesthetics and functionalities. The choice of material depends on the desired properties, applications, and budget of the printed part.

Image Source: MatterHackers

How does FDM 3D printing work?

Step 1: Design

The first step is to create or download a digital 3D model of the part that you want to print. You can design your own model using various software tools, such as CAD, Blender, or Tinkercad, or you can find ready-made models on online platforms, such as Thingiverse, MyMiniFactory, or Cults. The 3D model should be saved in a file format that is compatible with your 3D printer, such as STL, OBJ, or 3MF.

Step 2: Slice

The next step is to convert the 3D model into a set of instructions that the 3D printer can understand. The process is done by using slicing software, such as Cura, Simplify3D, or PrusaSlicer, that divides the model into thin horizontal layers and generates a G-code file that contains the parameters and commands for the 3D printer, such as printing speed, temperature, infill, and support structures. You can adjust these settings according to your preferences and the material that you are using.

Step 3: Print

The final step is to load the G-code file into your 3D printer and start the printing process. The 3D printer will heat the extruder nozzle and the build platform and feed the filament material from the spool through the extruder. The extruder will move along the X and Y axes, following the path of each layer, and deposit the melted filament onto the build platform. The build platform will move along the Z axis, lowering after each layer is completed. The process will repeat until the entire part is formed. Depending on the size and complexity of the part, the printing time can vary from minutes to hours.

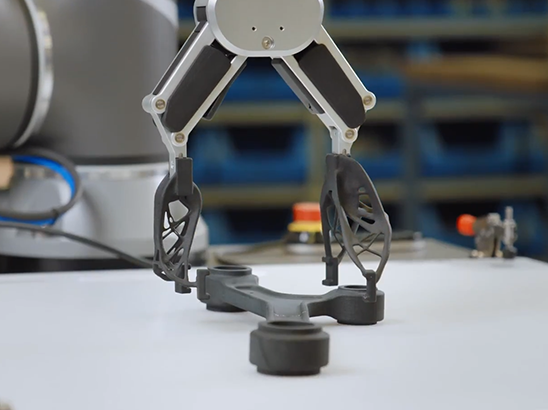

Step 4: Remove

Once the printing is done, you can remove the part from the build platform. You may need to use a spatula or a scraper to detach the part from the platform or use a heated bed to make the removal easier. You may also need to remove any support structures or rafts that were added to the part to improve its stability or quality. You can use pliers, cutters, or tweezers to remove them carefully.

Step 5: Post-process

The last step is to post-process the part to improve its appearance and functionality. You can use various methods, such as sanding, smoothing, painting, or gluing, to enhance the surface finish, color, or strength of the part. You can also use other techniques, such as drilling, tapping, or inserting, to add features or components to the part. The post-processing methods depend on the material and the application of the part.

Image Source: 3DPRINT

FDM Tolerances and Applications

FDM 3D printing tolerances are acceptable deviations from the intended dimensions of the printed part. Tolerances are important to ensure the fit, function, and quality of the part, especially when it is part of an assembly or has moving components. FDM tolerances depend on various factors, such as the material, the printer, the orientation, the layer height, and the post-processing of the part.

According to some sources, the typical 3D printer tolerance for FDM is:

± 0.5% (lower limit: ± 0.5 mm)

If a part with a dimension of 100 mm, the expected error range is between 99.5 mm and 100.5 mm. However, it is only a general guideline, and the actual tolerance may vary depending on the specific case and the printer settings. Some high-end FDM printers can achieve errors as low as 0.1%.

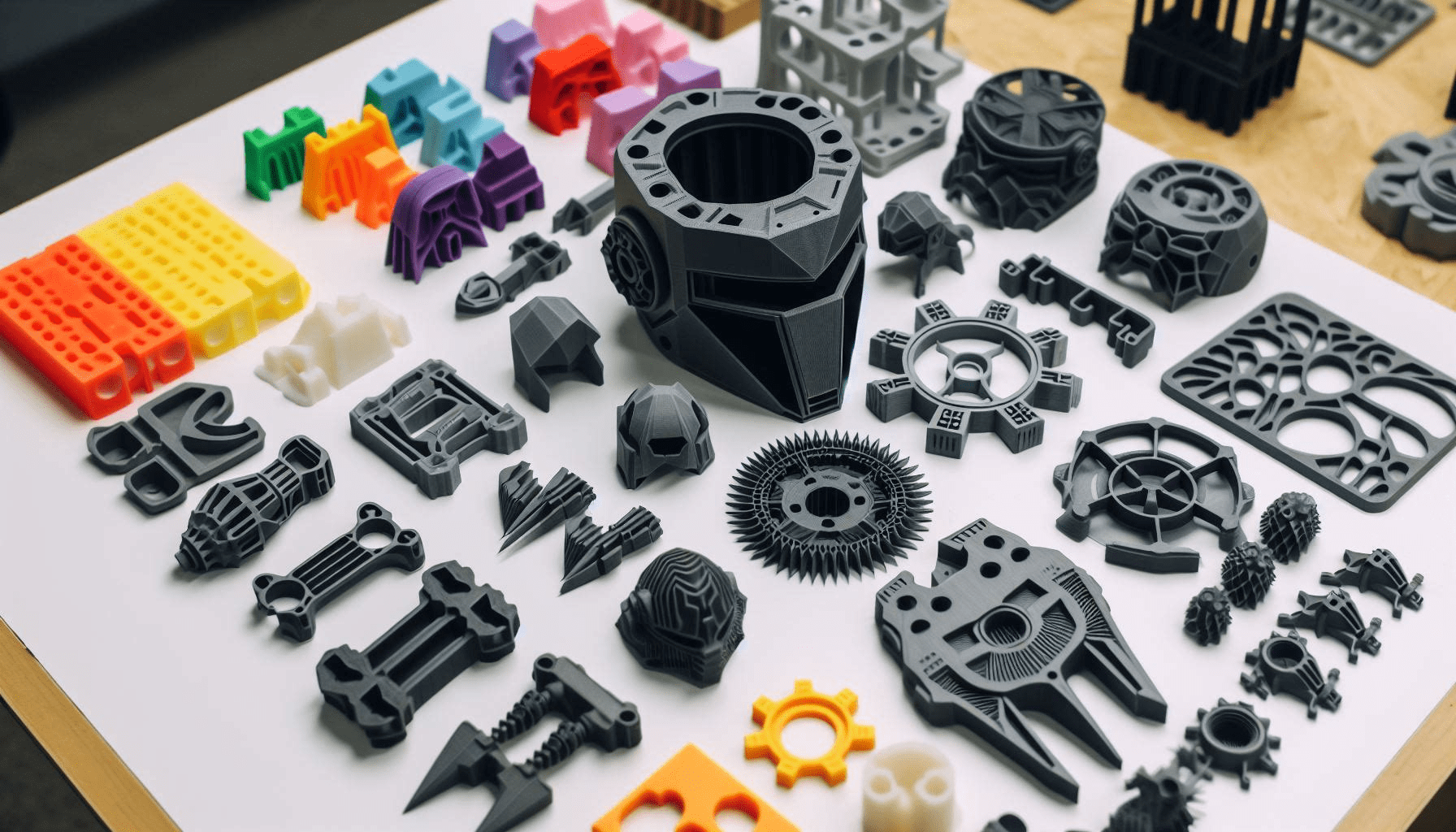

Applications

● Functional Prototypes: FDM can create parts that can simulate the performance and functionality of the final product, such as gears, housings, or enclosures. FDM can also print with high-performance materials, such as PPSF or PC, that can withstand high stress, heat, or chemicals.

● Production and Manufacturing Tools: FDM can create tools that can assist or enhance the production and manufacturing processes, such as jigs, fixtures, molds, or guides. FDM can also print with flexible materials, such as TPU, that can bend, stretch, or compress without breaking.

● Concept Models: FDM can create models that can demonstrate the design and appearance of the product, such as architectural models, sculptures, or figurines. FDM can also print with various colors and blends, such as glow-in-the-dark, transparent, or conductive PLA.

● Production Quality Parts: FDM can create parts that can be used as the final product or as a component of the product, such as medical devices, automotive parts, or consumer goods. FDM can also print with recyclable, biodegradable, or food-safe materials, such as PET or PLA.

Image Source: Stratasys

FDM Post-processing

FDM post-processing is the process of improving the appearance and functionality of FDM printed parts by applying various methods and techniques after printing. It can help remove layer lines, smooth the surface, enhance the color, or increase the strength of the part.

FDM post-processing can also add features or components to the part, such as holes, threads, or inserts. FDM post-processing can be divided into two categories, mechanical and chemical:

● Mechanical post-processing involves using physical tools or methods to modify the part, such as sanding, polishing, painting, or drilling. It can improve the surface finish, accuracy, or aesthetics of the part, but it may also introduce scratches, marks, or deformations.

● Chemical post-processing involves using chemical agents or solvents to modify the part, such as vapor smoothing, dipping, or metal plating. Chemical post-processing can create a smooth, glossy, or metallic surface on the part, but it may also alter the geometry, properties, or performance of the part.

Advantages and Disadvantages of FDM 3D Printing

Advantages of FDM 3D Printing

Affordability

FDM 3D printing is one of the most affordable 3D printing technologies, as it has low initial and operational costs. FDM 3D printers are cheap and easy to buy, maintain, and repair. FDM filaments are also inexpensive and widely available in the market.

Accessibility

FDM 3D printing is the most common and popular 3D printing technology, as it is simple and user-friendly. FDM 3D printers are easy to set up, use, and troubleshoot. It is also compatible with various software tools, such as CAD, Blender, or Cura, that can help design, slice, and print the models.

Versatility

FDM 3D printing can work with a wide range of thermoplastic materials, such as PLA, ABS, PETG, and Nylon, that have different properties and applications. FDM 3D printing can also print parts with complex geometries, overhangs, or hollows by using support structures or rafts that can be removed after printing.

Functionality

FDM 3D printing can create parts that simulate the performance and functionality of the final product, such as functional prototypes, production tools, or end-use parts. It can also print parts with high-performance materials, such as PC, PEEK, TPU or ULTEM, that can withstand high stress, heat, or chemicals.

Disadvantages of FDM 3D Printing

Resolution

FDM 3D printing has a lower resolution and accuracy than other 3D printing technologies, such as SLA or SLS, as it has a relatively thick layer height and a limited nozzle size. FDM 3D printing produces parts with visible layer lines, rough surfaces, and poor details, especially when printing small or curved features.

Strength

FDM 3D printing has a lower strength and durability than other 3D printing technologies, such as SLS or MJF, as it has an anisotropic structure and a weak layer adhesion. FDM 3D printing can produce parts that are prone to breaking, cracking, or warping, especially when exposed to high stress, heat, or moisture.

Support

FDM 3D printing requires support structures or rafts to print parts with overhangs, bridges, or holes, as it cannot print in mid-air. Support structures or rafts can increase the material waste, the printing time, and the post-processing efforts of FDM 3D printing.

Difference Between FFF And FDM 3D Printing

Fused filament fabrication (FFF) and fused deposition modeling (FDM) are two terms that are often used interchangeably to describe the same 3D printing technology. However, there is a subtle difference between them that relates to their origin and trademark status.

FDM is the original name of the 3D printing process invented and patented by Scott Crump, the co-founder of Stratasys, in 1989. FDM is a trademarked term owned by Stratasys, and it refers to the specific 3D printers and materials that they produce and sell.

FFF is the generic name of the 3D printing process, coined by the members of the RepRap project, an open-source initiative that aims to create self-replicating 3D printers, in 2009. It is free to use by anyone and refers to the general 3D printing technology and the machines and materials that are compatible with it.

In terms of the technical aspects, FFF and FDM are essentially the same. However, there may be some differences in the quality and performance of the 3D printers and materials that are labeled as FDM or FFF. FDM printers and materials are usually more expensive, but they also offer higher accuracy, reliability, and durability than FFF printers and materials.

Therefore, the main difference between FFF and FDM 3D printing is not in the technology itself but in the trademark and the quality of the products.

FDM 3D Printing Service

FDM 3D printing service is a convenient and cost-effective way to access the benefits of FDM 3D printing without investing in your printer or materials. It can help you create high-quality parts for prototyping, testing, or production quickly and flexibly.

Industrial FDM 3D printing is a more advanced and reliable version of FDM 3D printing that can produce parts with higher accuracy, repeatability, and durability. It can also work with high-performance materials, such as ULTEM, PPSF, or PEKK, that can withstand high stress, heat, or chemicals.

References:

[1] What is Fused Deposition Modeling (FDM) and its applications. https://engineeringproductdesign.com/knowledge-base/fused-deposition-modeling/

COMMENTS

- Be the first to share your thoughts!

Check out Our Special Offers

Featuring Process

- Coming Soon

Featuring Materials

- Coming Soon