FDM and SLS Meaning in 3D Printing

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a popular additive manufacturing process. In FDM 3D printing, a thermoplastic filament is unwound from a coil and supplied to an extrusion nozzle, which can turn the flow on and off. The nozzle is heated to melt the material. It can be moved in both horizontal and vertical directions by a numerically controlled mechanism, directly controlled by a computer-aided manufacturing (CAM) software package. [1]

In contrast, Selective Laser Sintering (SLS) is another additive manufacturing technique that uses a high-powered laser to fuse small particles of polymer powder. The laser selectively sinters the powdered material, tracing the cross-section of the object onto the powder bed. After each layer is completed, the powder bed is lowered, and a new layer of powder is applied on top. The process is repeated until the object is fully formed. [2]

Both FDM and SLS use plastic, what’s the difference?

FDM Filaments: FDM technology utilizes a continuous strand of thermoplastic filament, which is melted and extruded through a heated nozzle to build objects layer by layer. The filaments used in FDM are typically composed of standard thermoplastics like ABS, PLA, TPU, PC, Nylon, and various blends, which are known for their ease of use and versatility in creating durable parts.

Check out FDM Materials Guide Here

SLS Plastics: On the other hand, SLS does not rely on filaments but instead uses a fine powder of thermoplastic polymers. A high-powered laser selectively fuses this powder, layer by layer, to form solid structures. SLS plastics offer a wider range of material choices, including various types of nylon that provide different mechanical properties and are capable of producing more complex geometries.

Learn More 3DSPRO SLS 3D Printing Services and SLS Materials

SLS Metals: Beyond plastics, SLS technology also encompasses the use of metal powders, for example, nylon materials with aluminum.

How do they work?

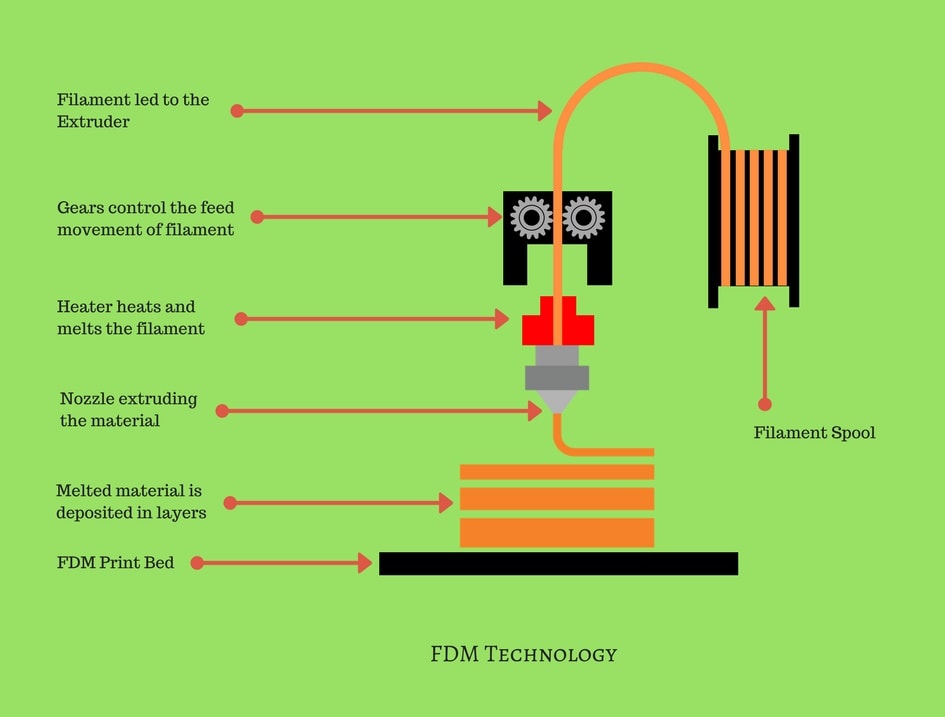

FDM 3D printing process starts with a digital model, which is divided into thin horizontal layers using software.

Throughout the printing process, thermoplastic filament is pulled from a spool and inserted into an extrusion nozzle. The nozzle is heated to the right temperature to liquefy the material and deposit it layer by layer onto the build platform.

The nozzle can move horizontally and vertically, guided by a computer following a digital blueprint. As the material cools, it solidifies, forming a strong structure. Repeat this sequential process, gradually constructing the object layer by layer until complete.

Image Source: MANUFACTUR3D

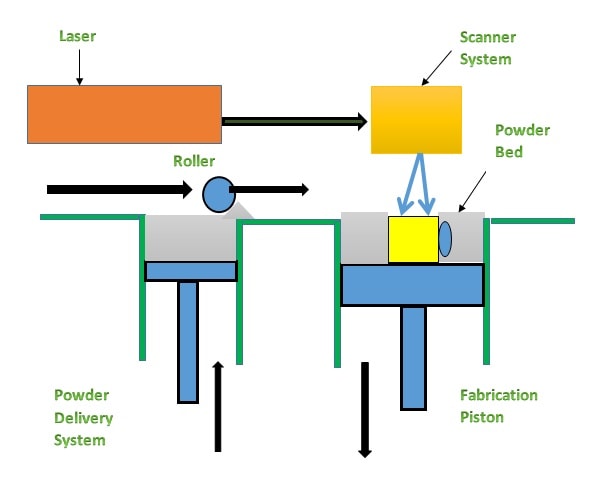

In the SLS 3D printing process, a high-power laser fuses powdered materials (usually plastic or metal) into a solid structure.

Initially, the printer spreads a thin layer of powder onto the build platform. The laser then scans the surface, melting the particles to form a single layer of the object.

Subsequently, the platform is lowered, and a new layer of powder is added. This laser sintering process iterates layer by layer until the entire object is created. Unlike FDM, SLS does not require support structures, as the unsintered powder supports the object during the printing process.

FDM and SLS Applications

FDM Applications

● Prototype Development: FDM is widely utilized for swiftly creating prototypes to evaluate design, fit, and functionality.

● Custom Manufacturing Tools: This tool is employed to fabricate bespoke manufacturing aids like jigs and fixtures, enhancing production efficiency.

● Direct Digital Manufacturing: FDM is capable of producing durable components that are ready for end-use, particularly in custom or low-volume production.

● Educational Models: Educational institutions leverage FDM to produce models that aid in teaching various subjects, from engineering to art.

● Healthcare Models: In healthcare, FDM is instrumental in crafting patient-specific anatomical models for surgical planning and medical training.

SLS Applications

● Complex End-Use Parts: SLS is ideal for parts that require high complexity and durability, such as those used in the aerospace and automotive industries.

● Medical Devices: Customized prosthetics and orthopedic implants are produced using SLS due to their ability to work with biocompatible materials.

● Functional Prototyping: SLS is used to create functional prototypes that can withstand rigorous testing.

● Customized Manufacturing: SLS's ability to produce small batches of customized parts makes it a preferred choice for personalized products.

● Architecture Models: Detailed architectural models can be created with SLS, providing a tangible representation of design concepts.

SLS and MJF 3D Printed Plastic Parts:

Only FOUR steps to get your SLS 3D-printed part done at 3DSPRO:

Upload Files → Customize & Configure → Get Instant Quote & Place Order → Get Parts within days

References:

[1] Patar, Azmi, et al. "Development of Dynamic Ankle Foot Orthosis for Therapeutic Application." 2012, https://doi.org/10.1016/j.proeng.2012.07.332.

[2] Color Jet Printing | Proto21. https://proto21.ae/color-jet-printing

COMMENTS

- Be the first to share your thoughts!