FDM and SLA Definitions in 3D Printing

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is an additive manufacturing process that builds parts layer by layer by selectively depositing melted material in a predetermined path. It uses thermoplastic polymers in filament form to create the final physical objects. FDM is widely used due to its efficiency, cost-effectiveness, and ability to produce durable and stable parts.

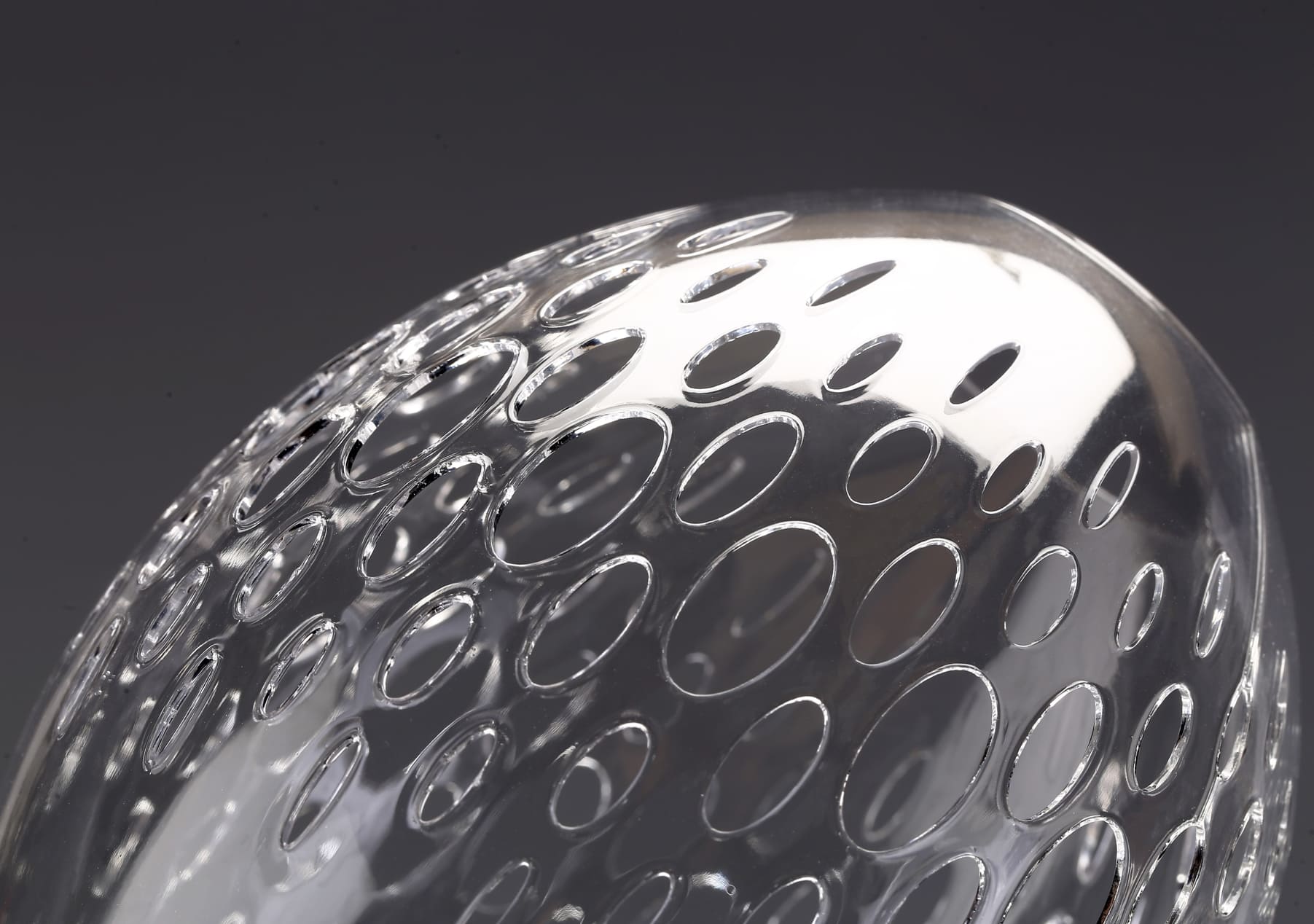

Stereolithography (SLA), on the other hand, is a form of 3D printing that belongs to the vat photopolymerization family. It works by selectively curing a polymer resin layer by layer using an ultraviolet (UV) laser beam. SLA is known for its high accuracy, isotropic parts, and smooth surface finishes, making it popular for detailed prototypes and production parts.

Both technologies have revolutionized the field of rapid prototyping and manufacturing, each with its unique set of capabilities and applications. In the following sections, we will delve deeper into their processes, materials, printers, and applications to understand how they compare and contrast.

Image Source: engineering.com

Printing Process

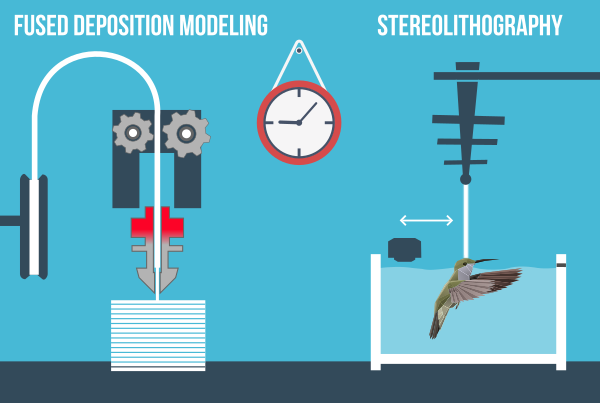

FDM Printing Process

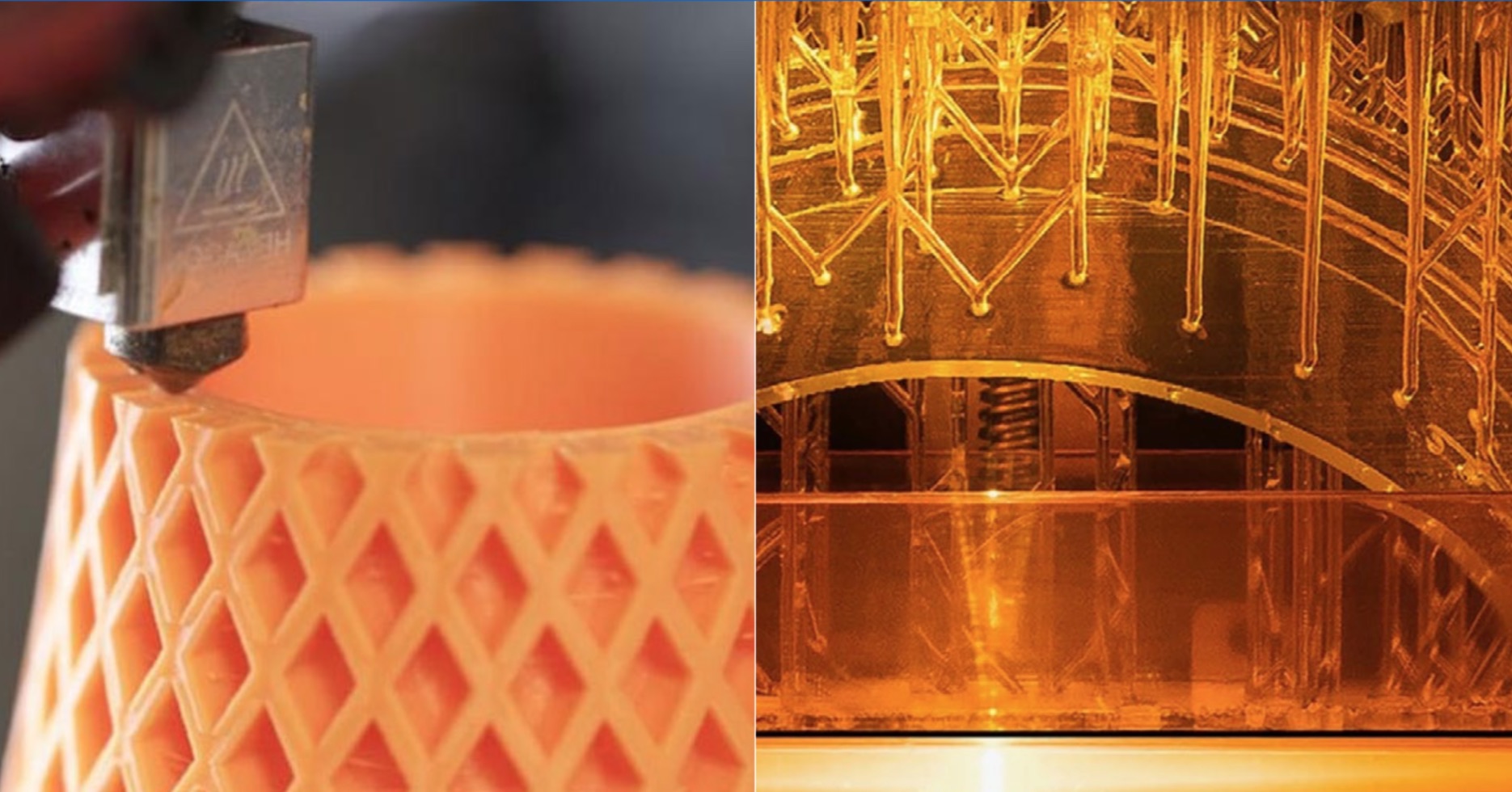

Fused Deposition Modeling (FDM) involves a series of steps to create 3D-printed objects:

Design: It starts with a 3D design created in CAD software.

Extrusion: Filament, typically a thermoplastic polymer, is unwound from a coil and supplied to an extrusion nozzle.

Deposition: The nozzle heats the material and extrudes it in thin strands, depositing it layer by layer onto the build platform.

Layering: The process continues, with each layer adhering to the previous one, until the object is fully formed.

SLA Printing Process

Stereolithography (SLA) also follows a distinct set of steps:

Design: Begins with a 3D model, usually designed in CAD software.

Resin Preparation: A vat of liquid photopolymer resin is prepared for printing.

Curing: A UV laser selectively cures and solidifies the resin, tracing the object’s cross-section for each layer.

Elevation: After each layer is cured, the build platform lifts to allow a new layer of resin to cover the surface.

Repetition: The process repeats, layer by layer until the object is complete

FDM is more common for its simplicity and cost-effectiveness, while SLA is preferred for its precision and quality of finish.

Image Source: Creality

Materials: Filament vs Resin

In the realm of 3D printing, materials play a fundamental role in determining the quality, functionality, and application of the printed objects. Two primary types of materials are used in FDM and SLA printing: filament and resin, respectively.

FDM Filament Materials

Filaments are the raw materials for FDM printers, usually available as spools of thermoplastic polymers. These materials are melted and extruded through a heated nozzle to build the 3D object layer by layer. Common FDM filaments include:

PLA (Polylactic Acid): Eco-friendly and easy to print, suitable for basic models and prototypes.

ABS (Acrylonitrile Butadiene Styrene): Durable and heat-resistant, ideal for functional parts.

PET (Polyethylene Terephthalate): Strong and water-resistant, often used for containers.

Nylon: Tough and flexible, perfect for mechanical components.

TPU (Thermoplastic Polyurethane): Elastic and durable, used for parts that require flexibility.

PC (Polycarbonate): High impact strength and temperature resistance for demanding applications.

Check out Our Material Guide for FDM 3D Printing

Image Source: HATCHBOX Black PLA Filament 1.75mm

SLA Resin Materials

Resins are used in SLA printers and come in liquid form. They are photopolymers that harden when exposed to a specific wavelength of light, typically from a UV laser. SLA resins can produce parts with high detail and smooth finishes. Types of SLA resins include:

Standard Resins: Provide good detail and are suitable for general prototyping.

Tough Resins: Designed for parts requiring higher strength and impact resistance.

Flexible Resins: Offer flexibility and are used for objects that need to bend or compress.

Castable Resins: Used for creating molds for casting metal parts.

Dental and Medical Resins: Biocompatible resins suitable for medical and dental applications.

Check out SLA 3D Printing Materials at 3DSPRO

Filament Printer vs Resin Printer

Filament 3D Printer

Filament 3D printers are the most widely adopted 3D printers for both personal and professional use. They work by melting thermoplastic filaments and extruding them through a nozzle, layer by layer, to build an object. Filament printers are known for their:

Versatility: Able to print with a variety of materials, including PLA, ABS, PETG, Nylon, and more.

Ease of Use: Generally user-friendly, with a straightforward printing process.

Affordability: They are typically less expensive than resin printers, both in terms of initial investment and the cost of materials.

Durability: The parts produced are mechanically strong, making them suitable for functional prototypes and end-use components.

Image Source: Bambu Lab P1S 3D Printer

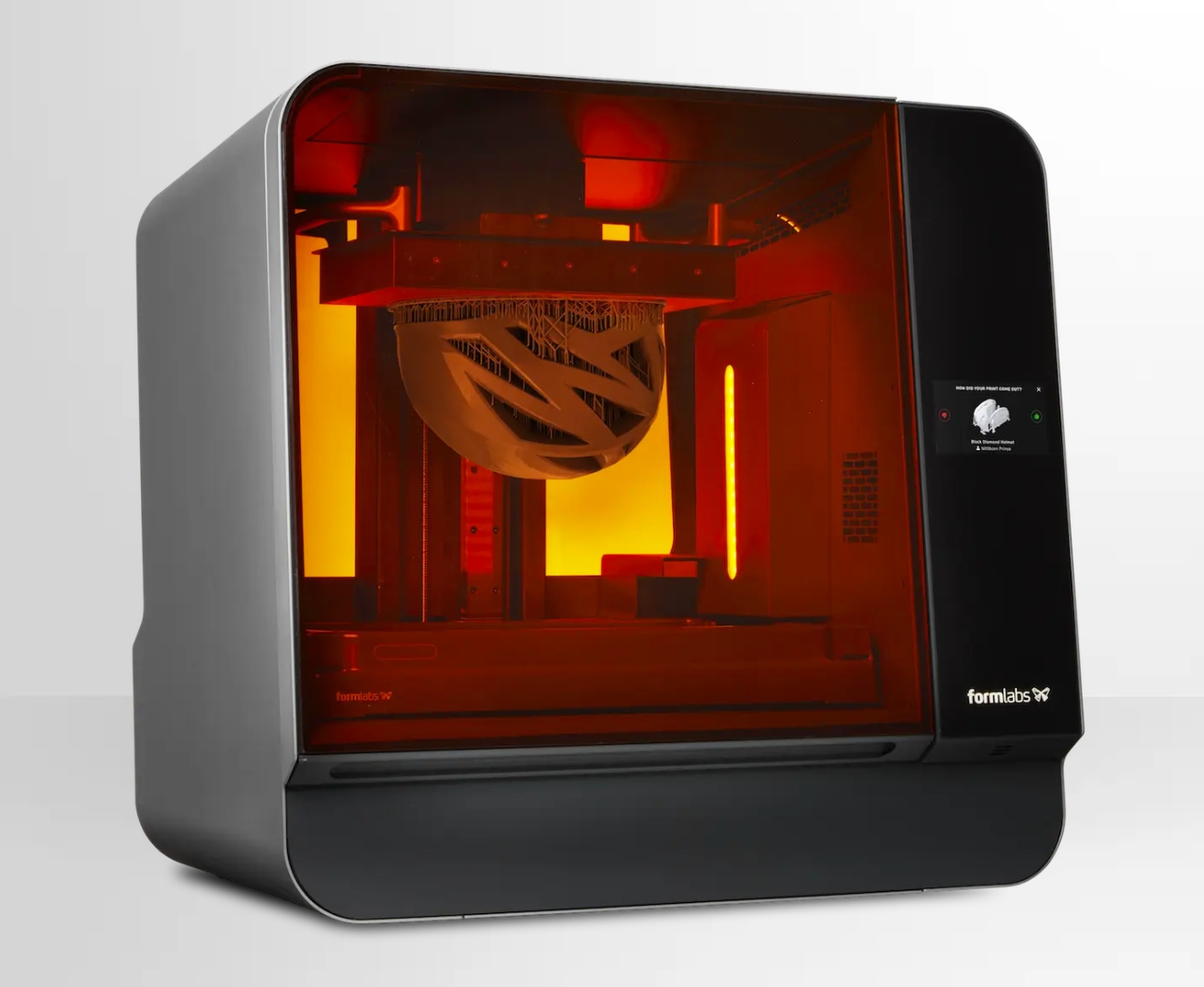

Resin 3D Printers

Resin 3D printers, on the other hand, use a vat of photopolymer resin that is cured by a light source—usually a laser or a digital light projector. SLA is one of the most common resin printing technologies. Resin printers are characterized by the following:

High Precision: Capable of producing parts with intricate details and a smooth surface finish.

Material Properties: The resins can be formulated for specific properties, such as toughness, flexibility, or transparency.

Post-Processing: Printed parts typically require cleaning and further curing, which can be a meticulous process.

Cost: Resin printers and materials are generally more expensive than FDM, but they offer superior detail and finish quality.

The choice between the two will largely depend on the specific requirements of the print job, such as the level of detail needed, the mechanical properties required, and the budget available.

Image Source: Formlabs 3L-Large Format Resin Printer

Applications

Applications of FDM 3D Printing

Fused Deposition Modeling (FDM) is a versatile 3D printing technology with a wide range of applications across various industries:

Prototyping: Quick and cost-effective production of prototypes to test form, fit, and function.

Manufacturing Aids: Creation of jigs, fixtures, and tooling to streamline manufacturing processes.

Prosthetics: Customized prosthetic limbs that are more affordable and quicker to produce than traditional methods.

Education: Teaching aids and models for educational purposes, allowing hands-on learning experiences.

Consumer Products: Customizable items like phone cases, footwear, and home decor.

Automotive: Parts for cars, including interior components and functional testing parts.

Applications of SLA 3D Printing

Stereolithography (SLA) is known for its high precision and is used in applications that require intricate details and a smooth surface finish:

Dental and Medical: Biocompatible prosthetics, surgical guides, and patient-specific models for pre-surgical planning.

Jewelry: Detailed patterns for casting and molds for intricate designs.

Engineering: High-precision components and complex geometries for functional testing.

Product Design: Prototypes with fine features and high-quality surface finish for design verification.

Audiology: Custom earpieces and hearing aid components tailored to the individual.

Art and Entertainment: Detailed figurines, models, and replicas for collectors and visual effects studios.

SLA 3D-printed Parts at 3DSPRO

Try 3DSPRO SLA 3D printing services by uploading your files now. 4 STEPS TO GET YOUR JOB DONE

COMMENTS

- Be the first to share your thoughts!