LCD 3D printing, also known as Masked Stereolithography (MSLA), has rapidly become one of the most popular resin-based 3D printing technologies. By using an LCD screen to selectively mask UV light and cure liquid resin layer by layer, MSLA printers deliver high-resolution prints with smooth surfaces and intricate details.

But here’s the catch: the material you choose is just as important as the process itself. Different resins offer different strengths, flexibilities, finishes, and costs. Selecting the right resin can mean the difference between a brittle prototype that cracks under pressure and a durable, functional part that performs as intended.

Core Resin Materials for LCD 3D Printing

1. Standard Resins

• Overview: The most widely used and affordable resin type.

• Properties: Good detail, smooth surface finish, moderate strength.

• Applications: Prototypes, figurines, visual models, and general-purpose prints.

• Pros: Easy to print, cost-effective, widely available.

• Cons: Brittle compared to engineering resins, limited mechanical performance.

2. Tough & Durable Resins

• Overview: Designed to mimic the strength and impact resistance of ABS plastic.

• Properties: Higher toughness, less brittle, withstands stress and handling.

• Applications: Functional prototypes, enclosures, and mechanical parts.

• Pros: Stronger and more durable than standard resins.

• Cons: Slightly more expensive, may require fine-tuning print settings.

Image Source: Formlabs

3. Flexible & Elastic Resins

• Overview: Rubber-like materials with varying levels of flexibility.

• Properties: High elongation, soft touch, bendable without breaking.

• Applications: Gaskets, grips, wearable parts, cushioning components.

• Pros: Unique mechanical properties not possible with rigid resins.

• Cons: More challenging to print, prone to warping or tearing if unsupported.

Image Source: Formlabs

4. High-Detail / Model Resins

• Overview: Optimized for ultra-fine resolution and smooth finishes.

• Properties: Crisp details, excellent surface quality, low shrinkage.

• Applications: Miniatures, jewelry prototypes, dental models.

• Pros: Exceptional detail and aesthetics.

• Cons: Limited strength, not suitable for functional parts.

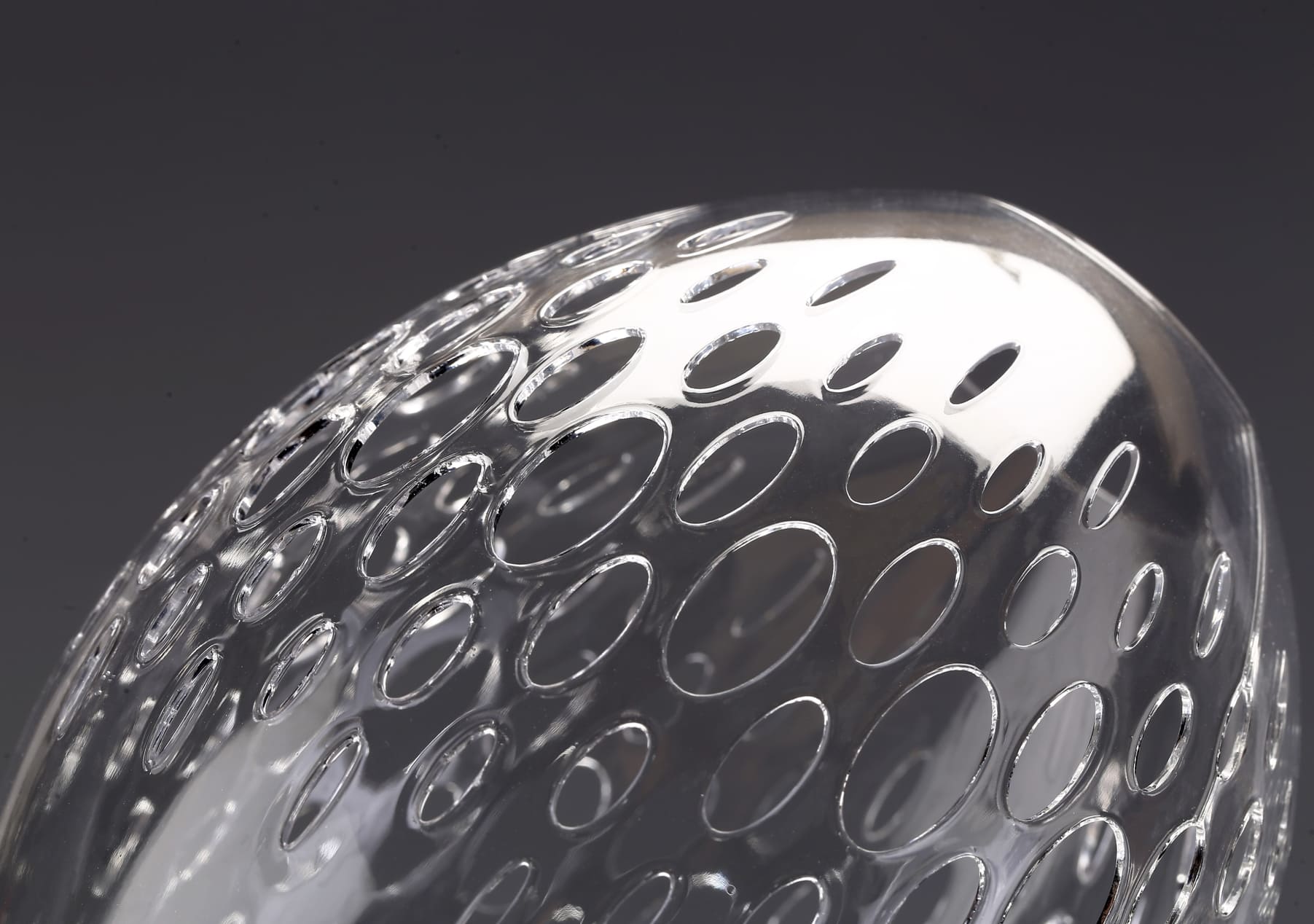

5. Engineering & Specialty Resins

• Overview: Advanced formulations for industrial and technical use.

• Properties: Heat resistance, chemical resistance, ceramic or glass-filled options.

• Applications: Functional prototypes, tooling, end-use parts.

• Pros: Tailored for demanding environments.

• Cons: Higher cost, often requires precise handling and curing.

Image Source: Formlabs

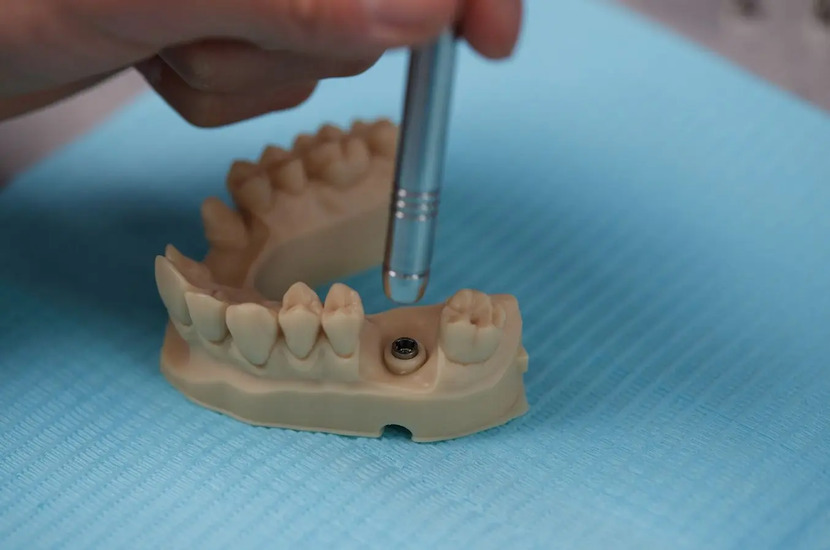

6. Biocompatible & Dental Resins

• Overview: Certified resins for medical and dental applications.

• Properties: Safe for skin or oral contact (when properly processed).

• Applications: Dental models, surgical guides, hearing aids.

• Pros: Regulatory compliance, specialized performance.

• Cons: Strict handling requirements, limited to professional workflows.

Image Source: Formlabs

Tips to Choose the Right Resin

1. Match Resin to Application

• Visual models & prototypes: Standard resin is sufficient.

• Functional parts: Tough or engineering resins are better.

• Wearables or flexible parts: Choose elastic or flexible resins.

• High-detail miniatures: Go with model/detail resins.

• Medical/dental use: Only certified biocompatible resins.

2. Balance Cost vs. Performance

• Standard resins are the cheapest but are limited in strength.

• Tough and engineering resins cost more but save time by reducing part failures.

• Specialty resins may be worth the investment for critical applications.

3. Consider Post-Processing Needs

• Some resins require longer curing times or special cleaning solutions.

• Flexible resins may need gentler handling during washing.

• Engineering resins often demand precise curing to achieve full strength.

FAQs

Q: What’s the difference between LCD, DLP, and SLA printing?

A: SLA uses a laser to cure resin point by point. DLP uses a projector to cure entire layers at once. LCD/MSLA uses an LCD screen to mask UV light, offering a balance of speed, detail, and affordability.

Q: Are all resins compatible with every LCD printer?

A: Not always. Some engineering or specialty resins require specific light wavelengths or exposure settings. Always check compatibility with your printer model.

Q: Can I mix different resins?

A: Mixing is possible but not recommended unless the manufacturer specifies compatibility. Inconsistent curing and unpredictable properties may result.

Q: How long do resin prints last?

A: With proper curing and storage, resin prints can last for years. However, exposure to UV light and humidity can degrade them over time. Engineering resins generally offer better longevity.

Q: Is resin printing safe at home?

A: Yes, if handled responsibly. Always wear gloves, use eye protection, and ensure good ventilation. Avoid skin contact and never pour uncured resin down the drain.

COMMENTS

- Be the first to share your thoughts!