Miniatures occupy a unique space in the world of 3D printing. Unlike large-scale prototypes or functional parts, miniatures demand exceptional detail resolution, smooth surface quality, and durability in a compact form. Whether for tabletop gaming, collectible display, or as master models for casting, the choice of material directly determines the success of the print.

The challenge is that no single material is universally “best.” Instead, the optimal choice depends on the balance between detail, strength, cost, and post-processing requirements. In this article, you will find the most common 3D printing materials for miniatures, compare their performance, and check an engineer’s perspective on matching materials to specific use cases.

Key Performance Criteria for 3D Printed Miniatures

Dimensional Accuracy & Detail Resolution

Miniatures often feature intricate textures, such as armor plates, facial expressions, or fine lettering. Materials must reproduce these features without distortion. SLA/DLP resins generally outperform FDM filaments in this category.

Surface Finish & Post-Processing

A smooth surface is critical for painting and presentation. Layer lines from FDM printing can detract from realism, while resin printing produces smoother results with less sanding.

Mechanical Properties

Miniatures are handled frequently, especially in gaming contexts. Brittle materials may chip or snap, while tougher materials withstand repeated use.

Material Cost & Availability

Resin and specialty filaments can be significantly more expensive than PLA. Designers must weigh whether the added performance justifies the cost.

Printer Compatibility

Not all printers support all materials. FDM printers excel with PLA and ABS, while SLA/DLP printers are required for resin-based materials.

Common 3D Printing Materials for Miniatures

PLA (Polylactic Acid)

• Pros: Affordable, easy to print, widely available. Minimal warping and low printer requirements.

• Cons: Limited detail resolution, visible layer lines, brittle under stress.

• Best Use Case: Beginners or large-scale miniatures where fine detail is less critical.

ABS (Acrylonitrile Butadiene Styrene)

• Pros: Stronger than PLA, can be smoothed with acetone vapor for improved finish.

• Cons: Warping, odor during printing, requires a heated bed and enclosure.

• Best Use Case: Durable miniatures or prototypes where toughness is prioritized over ultra-fine detail.

Standard Resin (Photopolymer)

• Pros: Exceptional detail resolution, smooth surface finish, ideal for intricate miniatures.

• Cons: Brittle, requires post-curing, and safety precautions are needed during handling.

• Best Use Case: Display models and tabletop gaming miniatures where visual fidelity is paramount.

Tough/ABS-like Resin

• Pros: Combines high detail with improved toughness compared to standard resin.

• Cons: Higher cost, still requires careful handling and curing.

• Best Use Case: Miniatures that will be frequently handled or transported.

Flexible Resin / TPU (Thermoplastic Polyurethane)

• Pros: High impact resistance, flexibility prevents snapping.

• Cons: Poor detail resolution, less suitable for aesthetic models.

• Best Use Case: Niche applications where bendability is required, not typical for display miniatures.

Specialty Resins (High-Detail, Dental, Engineering-Grade)

• Pros: Ultra-high resolution, tailored mechanical properties, professional-grade results.

• Cons: Expensive, limited availability, and often requires advanced printers.

• Best Use Case: Professional master models for casting, ultra-detailed display pieces.

Quick Material Comparison Table

|

Material |

Detail Resolution |

Surface Finish |

Durability |

Cost |

Best For |

|

PLA |

Low–Medium |

Visible layers |

Low |

$ |

Beginners, large minis |

|

ABS |

Medium |

Visible layers |

Medium |

$$ |

Durable prototypes |

|

Standard Resin |

High |

Smooth |

Low |

$$ |

Display, gaming minis |

|

Tough Resin |

High |

Smooth |

Medium |

$$$ |

Handled minis |

|

Flexible Resin/TPU |

Low |

Rough |

High Flex |

$$ |

Niche parts |

|

Specialty Resin |

Very High |

Smooth |

Varies |

$$$$ |

Professional masters |

Consider Surface Finishing

Surface finishing is often the deciding factor in miniature quality. Even the best material requires some degree of post-processing:

PLA and ABS

Layer lines are visible. Sanding, priming, and painting are essential. ABS can be acetone-smoothed for a glossy finish.

Resins

Produce smoother surfaces directly, but require washing and UV curing. Supports must be carefully removed to avoid surface damage.

Specialty Resins

Often require minimal finishing, but their cost makes mistakes expensive.

For painted miniatures, primer adhesion is critical. Resin surfaces generally accept primer more evenly than FDM prints, reducing preparation time. Check out Spray Painting Service at 3DSPRO >>

Consider Cost and Value

Cost is not limited to raw material price. Designers must consider:

1. Material Cost per Print: PLA is the most affordable, whereas specialty resins are the most expensive among commonly used materials for miniatures.

2. Printer Investment: SLA/DLP/LCD printers for resin are generally more costly than entry-level FDM machines.

3. Post-Processing Costs: Resin requires isopropyl alcohol, UV curing stations, and protective equipment.

4. Durability vs. Replacement: A brittle resin miniature may need reprinting, while a tougher ABS model lasts longer.

The value equation depends on whether the miniature is for display, gaming, or prototyping. For professional applications, the higher cost of specialty resins may be justified by the superior results.

Engineer’s Advices at 3DSPRO

From a 3DSPRO engineer’s standpoint, material selection is not about finding the “best” in absolute terms, but about matching the material to the intended use case.

1. If your miniatures are Display Models: Prioritize resolution and finish. Standard or specialty resins are ideal.

2. If your miniatures are Gaming Pieces: Balance detail with toughness. Tough resin or ABS-like resin provides durability without sacrificing too much detail.

3. If your miniatures are Prototypes: Cost efficiency and durability matter more than aesthetics. PLA or ABS is sufficient.

4. If your miniatures are Casting Masters: Ultra-high detail specialty resins are the professional choice, ensuring sharp features in the final cast.

Ultimately, you have to evaluate trade-offs: detail versus durability, cost versus performance, and ease of printing versus post-processing effort.

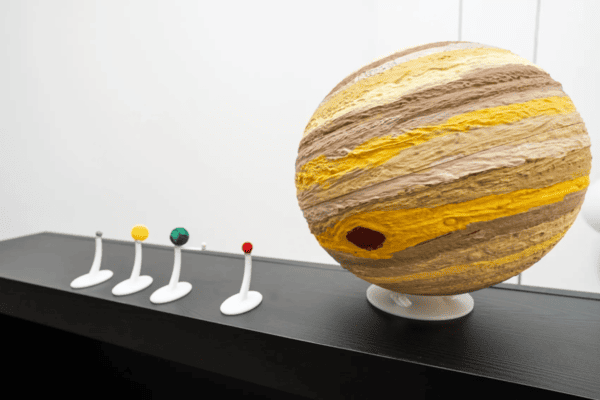

Image Copyright © 3DSPRO Limited. All rights reserved.

For creators who want professional results without the trial‑and‑error of home printing, 3DSPRO offers a complete solution for miniature production. Our services include high‑resolution resin 3D printing, precision surface finishing, and cost‑effective price matching to ensure you get the best value.

Whether you are producing tabletop gaming pieces, collectible display models, or master prototypes for casting, our team delivers consistent quality with engineering‑grade accuracy.

Simply upload your 3D files, receive an instant quote, and let us handle the rest. So, you can focus on design, creativity, and bringing your miniature concepts to life!

COMMENTS

- Be the first to share your thoughts!