The Olympic spirit pursues excellence, and 3D printing not only pursues excellence, but also pursues efficiency. There are many factors that affect the quality and efficiency of 3D printing, among which the layer height parameters are the basis for successful printing. If the layer height is set too high, it will directly affect the resolution of the final product; if the layer height is set too low, it will take a long time and affect efficiency.

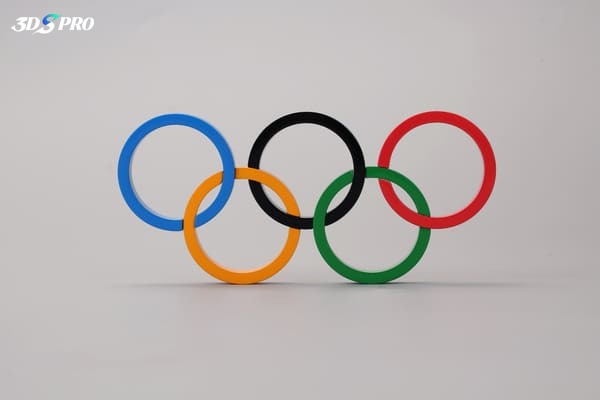

3DSPRO SLA 3D Printed Rings

Layer Lines That We Found on the Olympic Rings

As the 2024 Paris Olympics approaches, we are once again welcoming an exciting sporting event. In order to enhance our sense of participation in the Olympics, we have recently printed a series of Olympic-themed items, including the Olympic rings, the Paris Olympic torch, the Paris Olympic medals, etc. The entire process was both enjoyable and exciting, and we would like to share these experiences with you.

One notable aspect we must share is the common issue we encountered while printing the Olympic rings: the layer lines in 3D printing.

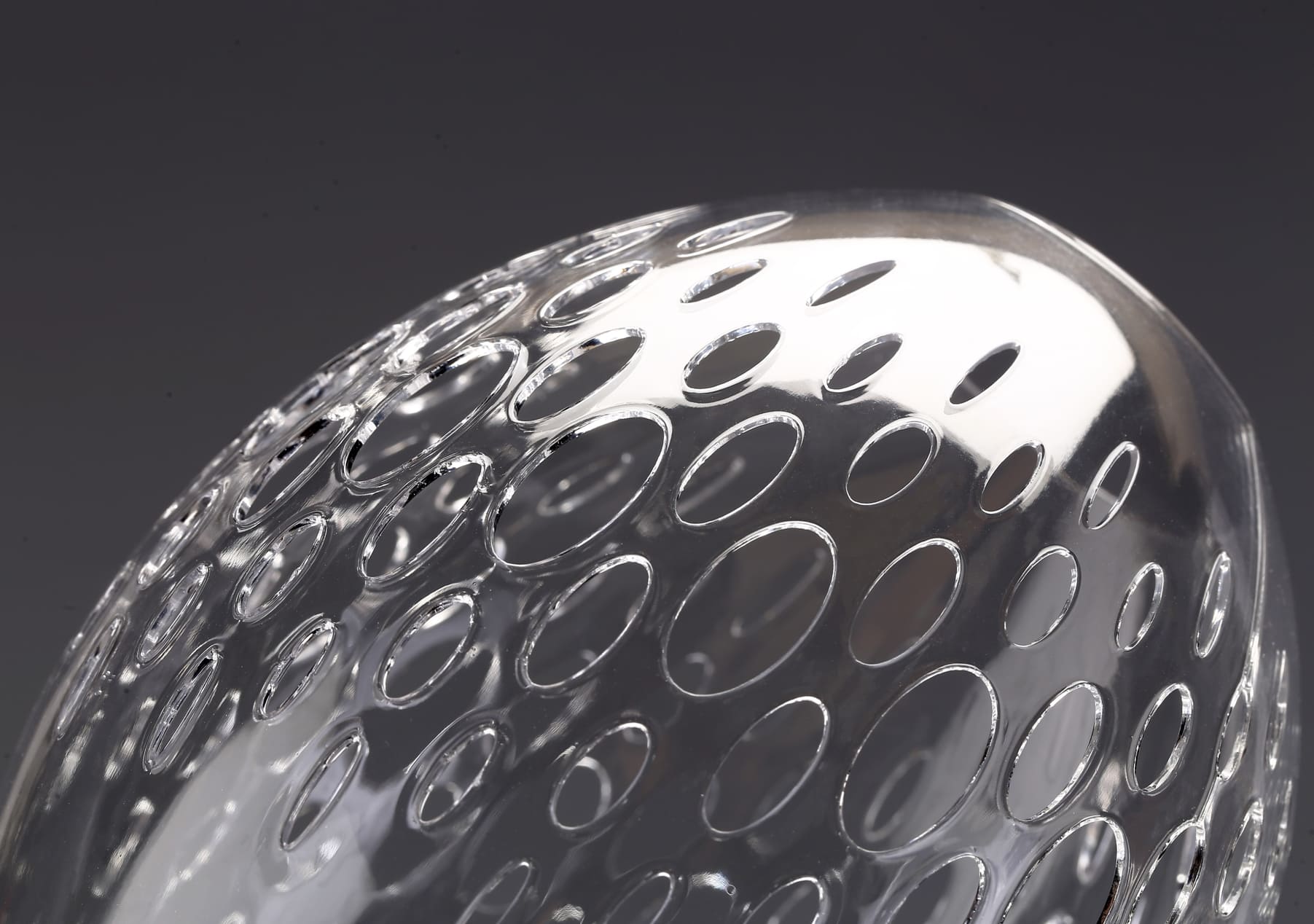

As seen on the surface of one of the rings from our first print, the layer lines are clearly visible, which is also a natural characteristic of 3D printing technology, where objects are built up layer by layer.

Visible Layer Lines

What are layer lines?

In 3D printing, layer lines are the visible little ridges or lines that appear on the surface of a printed object. These lines are a natural result of the additive manufacturing process, where the object is built layer by layer. Each layer is slightly offset from the previous one, creating an effect like a staircase.

The layer lines on some 3D printed parts are normal and expected. But layer lines can become problematic if they are too obvious or uneven due to various factors such as incorrect printing temperature, mechanical issues, or high print speed.

One of the most important factors affecting layer lines is the layer height between layers. The thicker the layer height, the rougher the layer lines on the surface of the print.

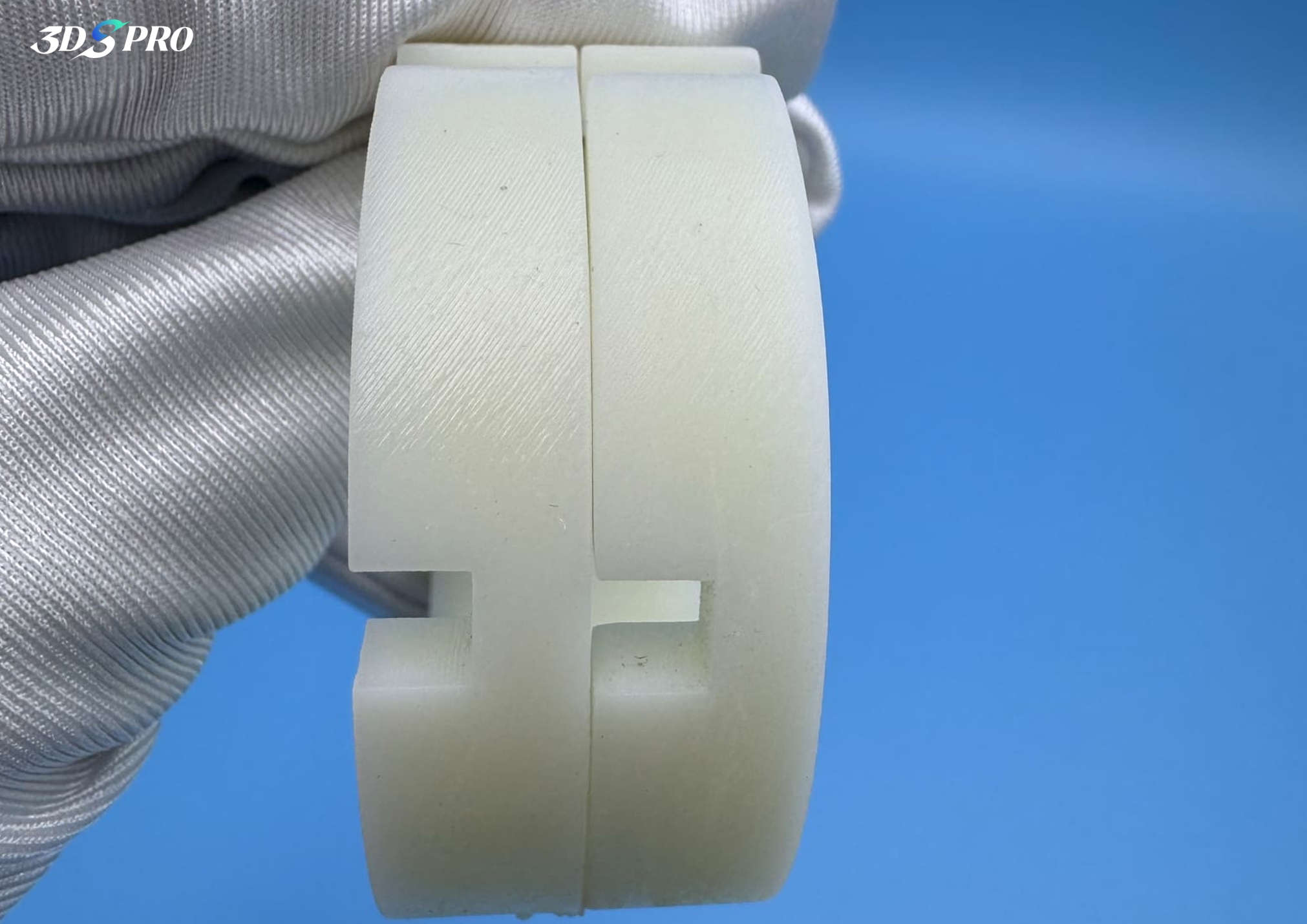

Visible Layer Lines and Remaining Supports

3D-printed Olympic Rings Printing Parameters

● Technology: SLA 3D Printing

● Material: Quality Resin White (Somos® Ledo 6060)

● Layer Height: 0.025mm

In the process of FDM printing, we all know how crucial the first layer is to the final product. If the first layer is too thin, the distance between the nozzle and the print bed will be very close, potentially damaging the original shape of the first layer. Conversely, suppose the first layer is too thick. In that case, the gap between the first layer and the bed will be too large, resulting in a lack of adhesion, which will undoubtedly lead to a distorted final product or even prevent the print from completing successfully.

However, in SLA printing, the issue of the first layer can be largely eliminated because SLA uses a high-energy laser beam to dance in the resin tank and to cure the specific shape. More precisely, the 3D printing resolution is significantly affected by the layer height in our case.

In this case, we used SLA and Somos® Ledo 6060 resin to print the Olympic rings. Typically, objects printed with SLA have relatively smooth surfaces. However, the layer lines on the ring (see image below) are still visible, which made us wonder: could the layer height setting have such a significant effect on the final product, even if it was set at the minimum layer height? If we set the layer height to 0.1mm, the surface will probably be quite rough (but the print speed will probably be faster).

Layer line problems are inevitable.

Troubleshooting

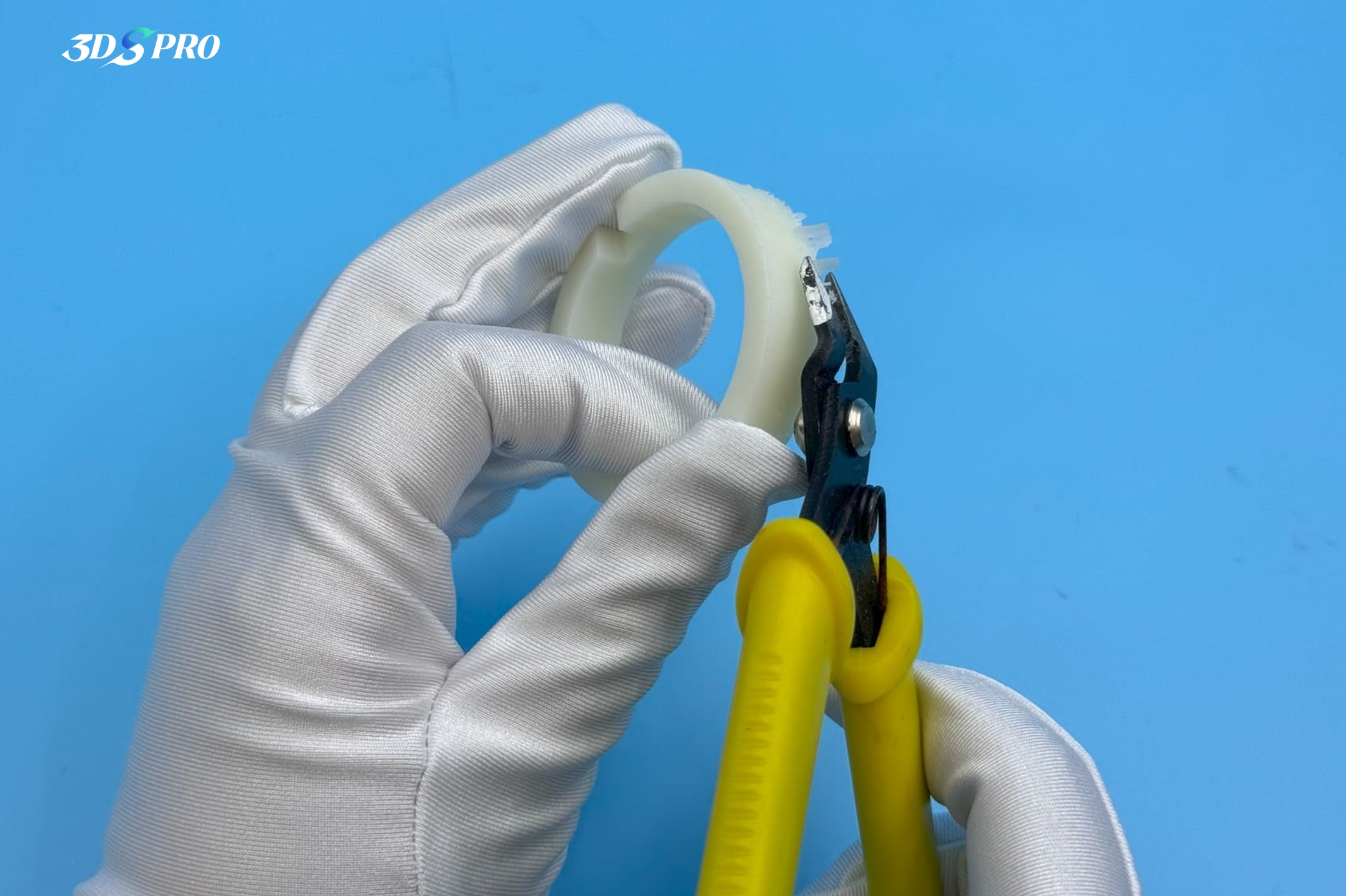

● Post-processing: Removing Supports and Sanding

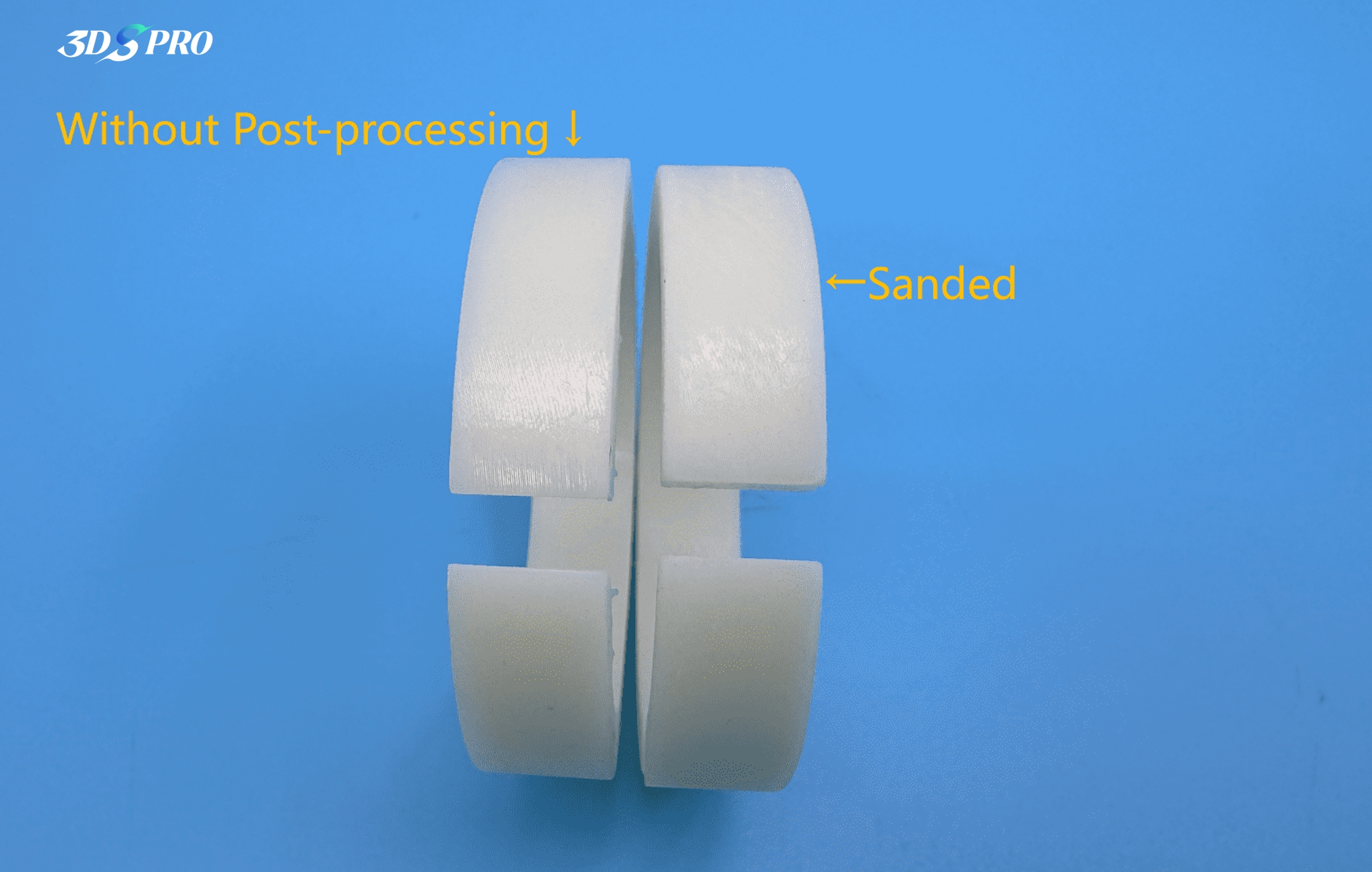

To address the issue of layer lines, post-processing is essential. We used sanding to smooth the surface, as shown in the image below. The layer lines and support structures are removed and sanded, resulting in a smooth surface finish. The smoothing process is crucial for subsequent post-processing steps, such as spray painting, electrocoating, polishing, etc.

However, when you order and manufacture with 3DSPRO, you don’t have to worry about receiving prints with layer lines or blemishes. Beyond price matching, we ensure your part meets your expectations. Our dedicated 3D Plus™ Post-processing Services and professional customer support team handle every issue with precision and care.

The Differences

The ring on the left was raw-printed, while the ring on the right was sanded. Both have the same layer height. Without post-processing, layer lines are obvious on the surface finish and the finish is more shiny. While, the sanded one has a smoother surface finish and the finish is more matte.

Final Thoughts on 3D Printing Resolution

We have long known that layer height can significantly impact the resolution of the final 3D-printed product. However, we rarely consider that even within the standard range, the impact of layer lines is still significant. Therefore, it is crucial to balance 3D printing speed and the quality of the final product.

Additionally, if the layer lines on the printed product are too obvious, simple sanding may not be effective in hiding the blemishes. This will also greatly affect the quality of post-processing and, in some cases, may even make post-processing impossible. Therefore, it will also affect the accuracy of the final part.

These are our interesting insights on layer height. We greatly appreciate your thoughts and experiences regarding layer height, as they enrich our collective knowledge on this topic. Please share them with us.