The Olympic rings are the globally recognized symbol of the Olympic Games. They consist of five intertwined rings of equal size, colored from left to right: blue, yellow, black, green, and red.

The rings symbolize the unity of the five continents and the meeting of athletes from all over the world at the Olympic Games. Contrary to popular misconception, the colors of the rings do not correspond to specific continents. Instead, the combination of the five colors with the white background represents the colors of the national flags of all the countries at the time the symbol was created.

The Olympic rings were first introduced by Pierre de Coubertin in 1913 and have since become a powerful representation of the Olympic Movement and its values.

We 3D Printed Olympic Rings

● Process: SLA

● Material: High-quality resin

● Post-processing: Fine sanding and painting

The Olympic rings are the symbol of the Olympic Games, so we had to make the 3D printed replicas for this Olympic season. We started with a 3D design, and we chose not to 3D print the Olympic rings in one piece because we wanted the interlocking structure to represent the spirit of unity and harmony.

SLA and high-quality resin were used to make the five rings, each with a different interlocking assembly structure. The rings were then support removed, fine sanded, and spray painted to achieve the effect. Here are the final rings we made:

3D Printed Raw Parts

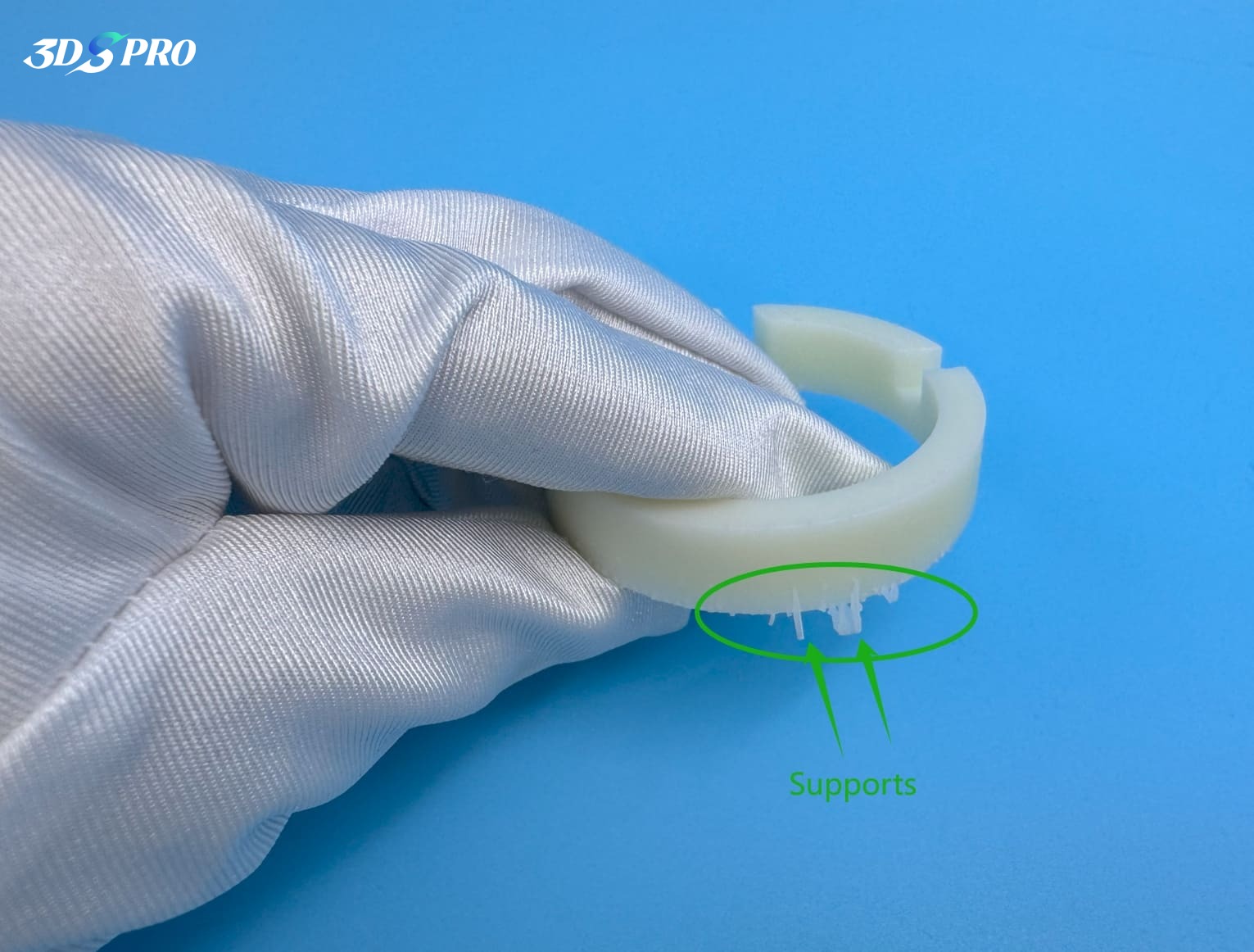

Here’s the 3D printed red ring without any post-processing; you can see it still has the supports on it:

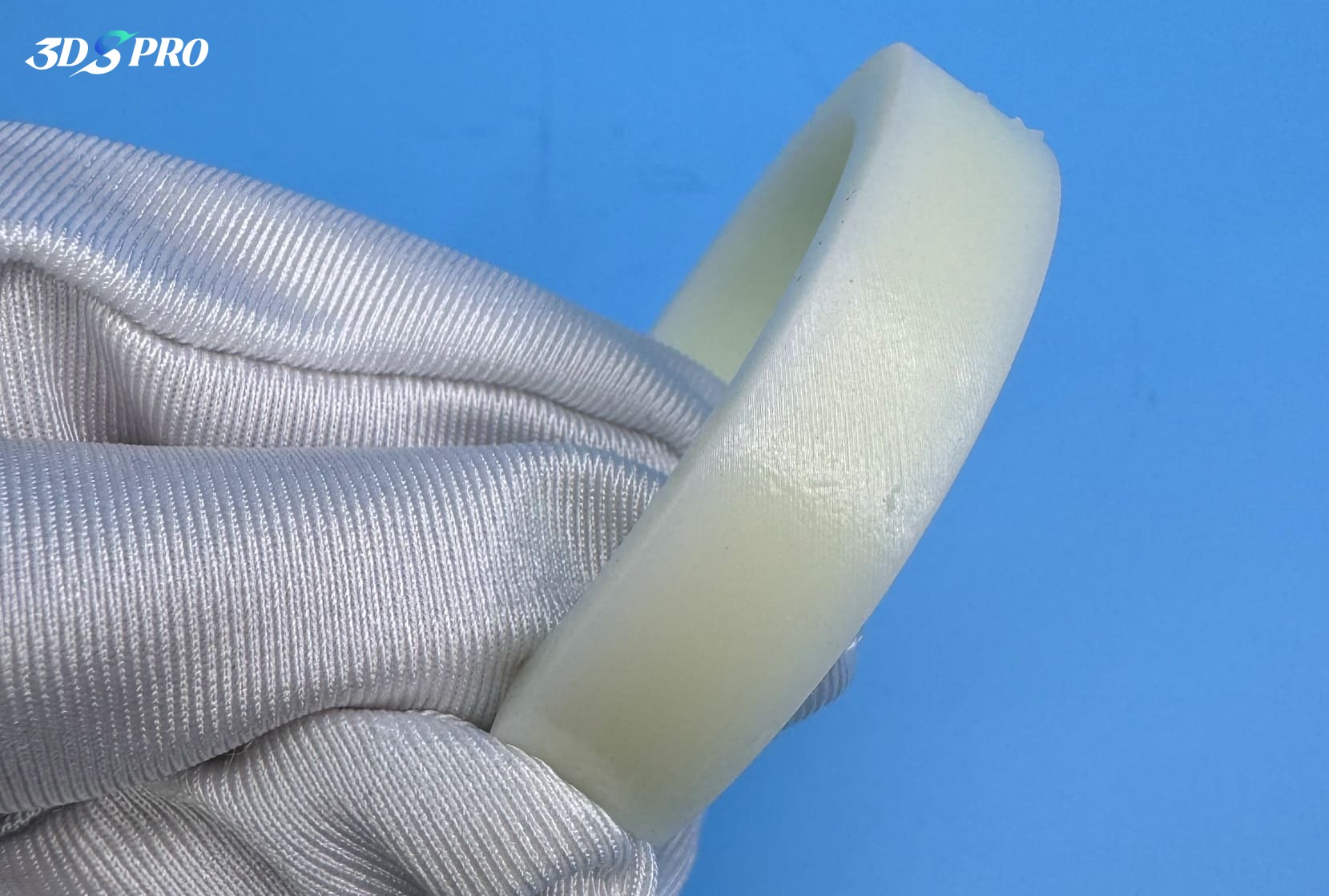

And the layer lines are visible too:

Supports Removing

Once the print is complete, the next step is to remove the supports. We use breakaway supports in our SLA printing process to allow for easy removal of support structures and reduce build chamber space usage.

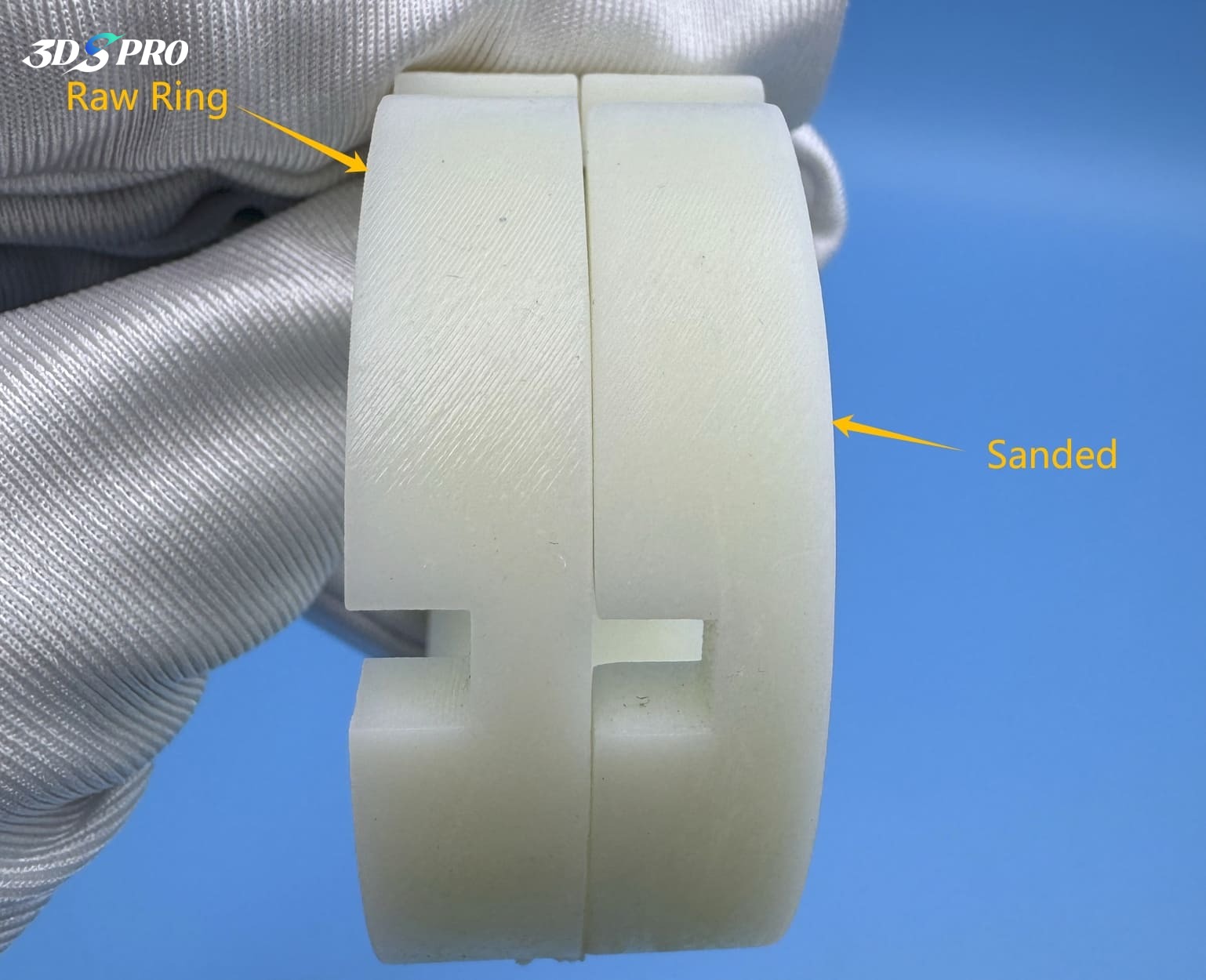

Sanding

Sanding is the next step. This process smooths the surface of each ring, removing any imperfections left after the supports have been removed. It is a laborious process that transforms the rough texture into a smooth surface for final display. Not only does sanding enhance the visual appeal of the rings, it also prepares them for the next stage - spray painting. The sanding process begins with coarse sandpaper to remove larger imperfections, then uses finer grits to achieve a smooth surface.

Spray Painting

Spray painting in 3D printing is one of the most popular post-processing techniques used to enhance the appearance of printed objects. It involves applying paint to the surface of a 3D printed part to add color, improve the surface finish, and sometimes protect the part.

The goal of spray painting is to achieve a smooth, uniform surface that hides the layer lines of 3D printed objects, giving them a more professional, high-quality, and aesthetic appearance.

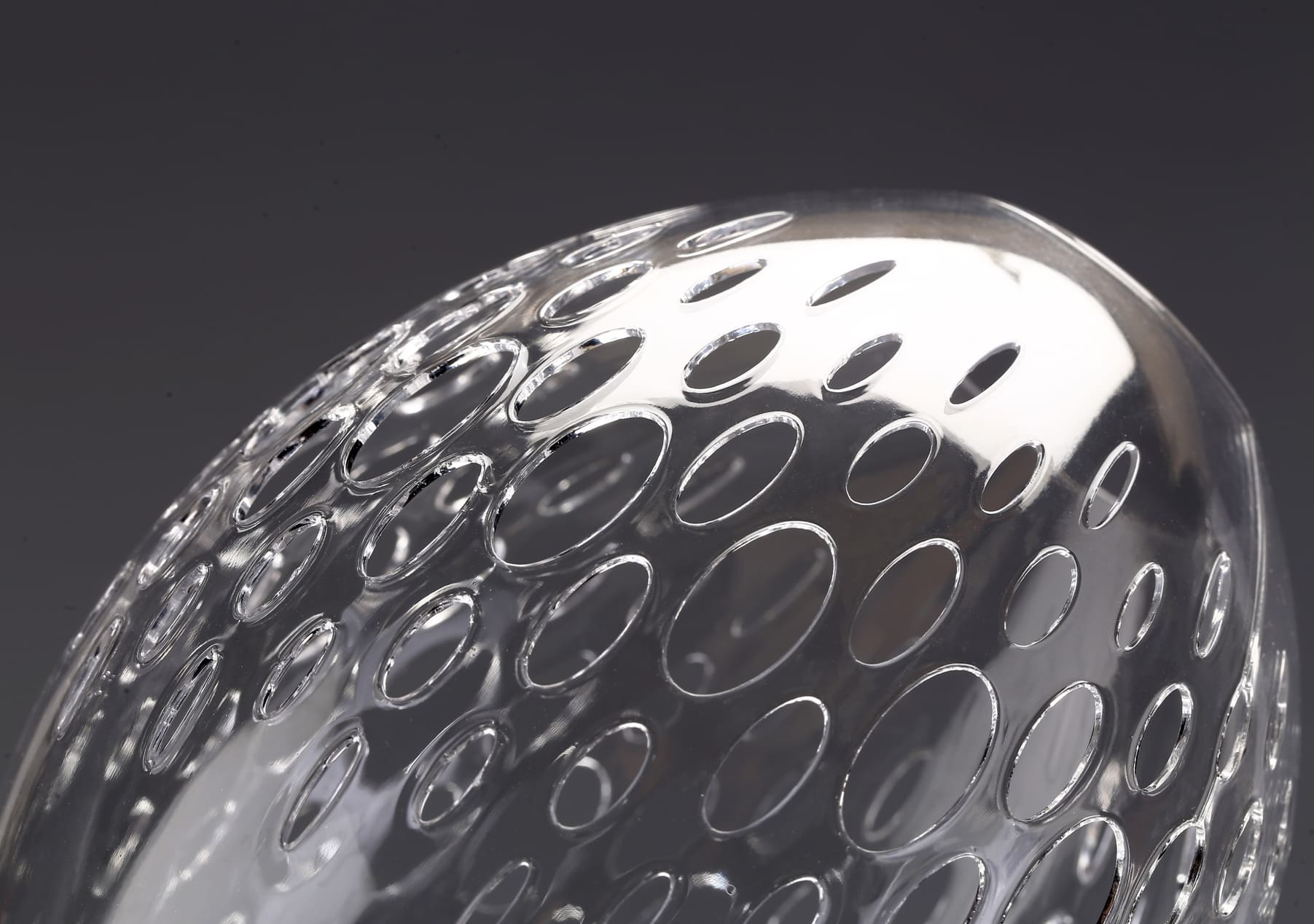

In our 3D printed Olympic rings example, we used gloss paint. Gloss paint provides a high gloss. It has a reflective sheen similar to a mirror. So you can see the stunning and shiny rings:

However, using gloss paint has challenges because any deviation will impair the visual appeal and make the surface susceptible to scratches. It is critical to apply gloss paint evenly to maintain its aesthetic appeal and minimize the risk of surface defects.

In addition, gloss paint is widely used to enhance the surface finishes of smart hardware, home appliances, plastic parts, etc.

3DSRO SLA 3D Printing and 3D Plus™ Solutions

3DSPRO SLA 3D Printing Services

With more than 150 running machines and more than 15 resin materials, we are able to provide high-quality, fast-delivery online SLA 3D printing services.

Here are the key data of our SLA printing capabilities for your reference:

|

Price |

Lead Time |

Maximum Printing Size |

Tolerance |

|

$ |

48 Hours/72 Hours |

2100mm * 1700mm * 810mm |

± 200μm or 0.2%mm |

SLA 3D printing excels at producing parts with rich details and high precision, and is ideal for producing complex geometries. Its versatility extends to a wide range of materials, from strong, flexible to translucent resins, to meet the needs of different fields such as product design, engineering and healthcare.

3DSPRO 3D Plus™ Solutions

Our 3D Plus™ solutions represent a comprehensive set of services designed to bring 3D printing projects from concept to reality with professional-grade quality. 3D Plus™ includes hardware and software solutions designed to enhance the functionality, durability, and aesthetics of 3D printed objects, ensuring they can be used for professional purposes.

Hardware solutions are advanced post-processing technologies and finishing options. We offer more than 50 hardware solutions for 3D printed parts, such as painting, plating, electrophoresis, powder coating, screen printing, tumbling, vibration smoothing, steam smoothing, anodizing, etc. Our software solutions provide user-centric services to ensure our customers can access these solutions online in a transparent and efficient way.

Our 3D Plus™ solutions provide the tools and expertise you need to improve the quality of your 3D printed products.