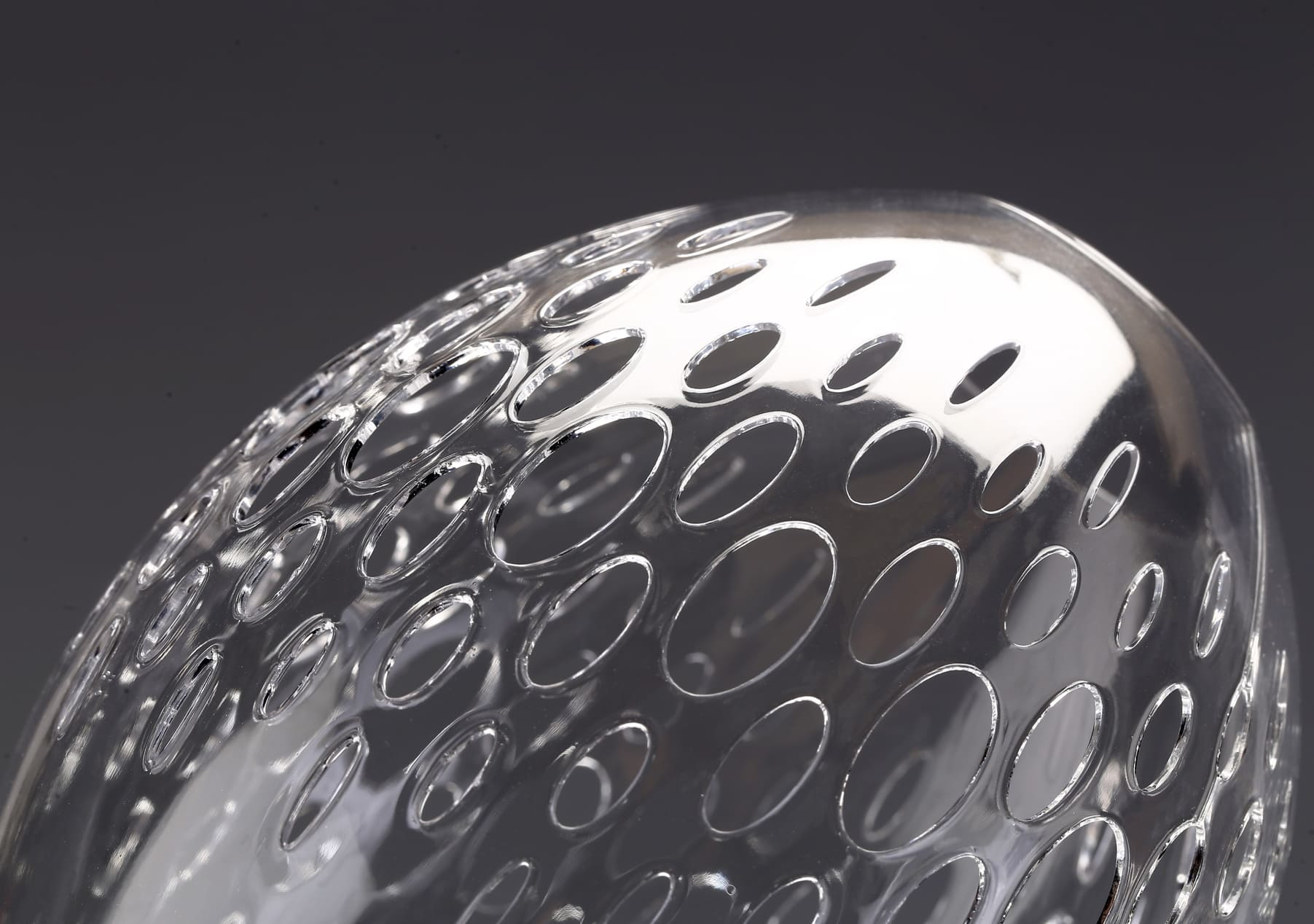

The medals for the Paris 2024 Olympics are quite special and unique. Each medal contains an original fragment of the Eiffel Tower, symbolizing the connection between this iconic building and the event. The medals are a perfect blend of tradition, history, and modern design, making them unforgettable prizes for athletes.

3D Printed Paris Olympic Medals

● Process: SLA 3D Printing

● Material: Quality Resin White

● Post-processing: DIY

We created three 3D printed Paris Olympic medals using Stereolithography (SLA). Olympic medals symbolize the pinnacle of athletic achievement and the spirit of international sporting competition. Olympic medals represent the hard work, dedication, and excellence of athletes from all over the world. By 3D printing replicas, we celebrate Olympic values and hold a part of the Olympic legacy in our own hands. It was fun and meaningful.

SLA is a high-precision 3D printing process that uses a laser to dance over a tank of resin and create our solid medals, giving them a fine finish. For this project, premium resin was the material that ensured the medals had a smooth surface and durable structure. After printing, we painted the medals to enhance their appearance and durability.

Before painting, we washed the prints with isopropyl alcohol to remove any uncured resin, cured them under UV light to strengthen the material, and used sanding to achieve a perfect surface. Finally, we gave them a metallic finish.

DIY Medals

Since each original medal contains a piece of the Eiffel Tower, we wanted to replicate a similar surface finish. We decided to DIY the surface finishes of our 3D printed medals.

First, we sprayed each medal with gold, silver, and bronze metallic paint lacquer, leaving the center parts unpainted. Then, we painted the middle sections in a gray-black color, intentionally leaving some blemishes for an authentic look. Here are the stunning 3D printed medals!

High-fidelity or just a prototype?

This is how we made the 3D printed Paris Olympic medals. We wouldn't say these medal 3D prints are 100% replicas, but they are very similar to the originals, at least on the front of the medals. Since we didn't mention above that the design on the back of the medals is not printed, we left it blank.

We all know or acknowledge that 3D printing is one of the most effective manufacturing methods for making prototypes. However, despite rapid prototyping, how much fidelity can 3D printing bring to our projects?

In the case of our medal 3D prints, the reason we didn’t print the reverse side of the medal was because the design was full of intricate details with small engraved and embossed layer height that were difficult to print successfully. Therefore, we abandoned the reverse side while we evaluated the printability and capabilities of SLA 3D printing, and we ended up with three lower-fidelity prototypes. However, the difference is that we post-processed the 3D printed medals and gave them gold, silver, and bronze colors. They ended up with improved fidelity (not 100%).

Therefore, the whole process in our case is: 3D Designs >> Printability >> 3D Printing >> Post-processing.

● Whether we can make those prototypes depends Stage ‘Printability’, and then we decide to modify or enhance the 3D designs.

● Whether we can ensure a high-fidelity outcome depend on by Stage ‘Post-processing’, and then we use spray painting to make stunning medals.

Prototyping and high fidelity are not in conflict. The question is how do we improve the fidelity of our prototypes, and the answer is to ensure printability and use post-processing methods.

3DSPRO Can Make High-fidelity Prototypes for You

If you choose 3DSPRO, you only need to provide the 3D design throughout the entire process of your 3D printing project. We take care of the rest of the printability, 3D printing, and post-processing, giving you peace of mind.

We have professional engineers to evaluate printability; we provide 5 types of 3D printing services; and our 3D Plus™ solutions provides more than 30 post-processing options. In addition, our customer success managers follow up the entire service and manufacturing process and help you solve every problem. You can get a high-fidelity prototype within a week.

Plus, we have special deals for you during the Olympic and Paralympic Games! Click here to check it out!

Try our instant quote system and get a price match.