How does 3D printing affect the footwear industry?

3D printing technology has ushered in a transformative era for the footwear industry, reshaping the landscape of design, production, and distribution.

Revolutionizing Design and Prototyping

Traditionally, shoe design and prototyping have been labor-intensive processes requiring multiple iterations to achieve the desired look and feel. 3D printing accelerates this process by allowing rapid prototyping directly from digital models, significantly reducing the time from design to production.

Customization and Personalization

3D printing enables the creation of shoes tailored to individual preferences and anatomical needs. This level of customization was once a luxury but is now increasingly expected by consumers, who seek footwear that reflects their unique style and fits their specific foot shape.

Sustainability and Waste Reduction

The additive manufacturing process of 3D printing minimizes material waste, as it builds products layer by layer, using only the necessary amount of material. This eco-friendly approach aligns with the growing consumer demand for sustainable products.

Localizing Production

With 3D printing, manufacturers can produce shoes closer to the consumer, reducing the need for large-scale factories and extensive shipping. It not only cuts down on carbon emissions but also allows for quicker response to market trends.

Material Innovation

The search for new materials suitable for 3D printing is ongoing, with a focus on durability, flexibility, and comfort. These materials are poised to open up new possibilities for shoe performance and aesthetics.

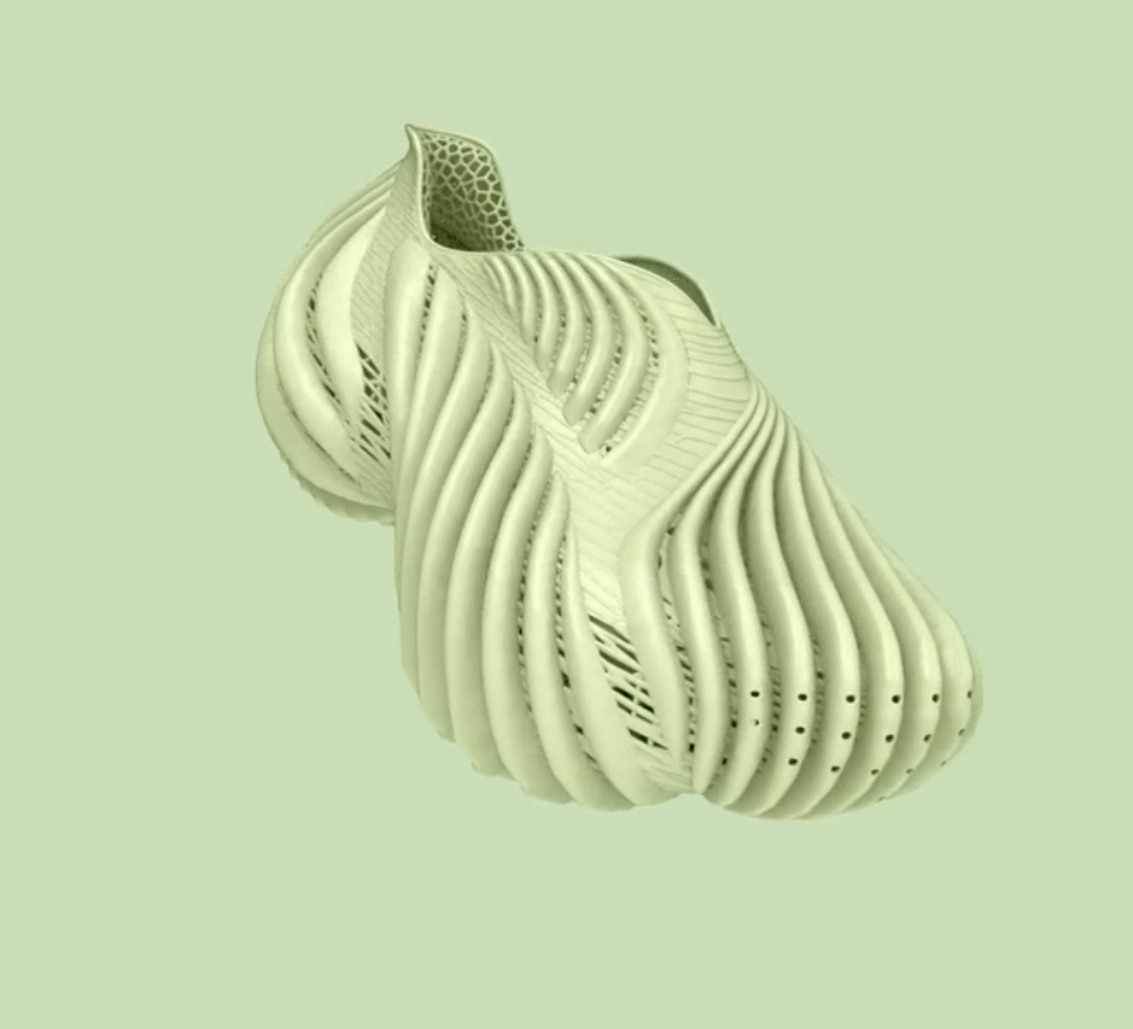

Image Source: Aliveform

Make Fashion Functionable and Sustainable

3D printing empowers designers with unprecedented freedom to experiment with complex geometries and intricate details.

Besides, the agility of 3D printing in prototyping allows designers to iterate rapidly, refining their visions into tangible products with speed and accuracy, which accelerates the design process and encourages bold experimentation and risk-taking in design. More importantly, 3D printing process aligns with the industry’s shift towards more sustainable practices, reducing the environmental footprint of fashion production.

3D Printed Shoes on the Market

1. Adidas 3D Printed Shoes: 4DFWD

Adidas is at the forefront of the 3D printed footwear revolution with its innovative 4D shoes. These sneakers feature a distinctive 3D printed midsole crafted using Digital Light Synthesis technology, a process developed in collaboration with Carbon, a tech company specializing in this field. The midsole’s unique lattice structure is designed to provide precise cushioning and support, adapting to the wearer’s footfall to ensure optimal comfort and performance.

The 4D shoes are a blend of functionality and style, with a Primeknit upper that ensures breathability and a snug, sock-like fit. The outsole, made from Continental™ Rubber, provides excellent traction, making these shoes suitable for a variety of activities, from running to casual wear.

Image Source: Adidas

2. Nike Flyprint: 3D Printed Textile Upper

Nike’s commitment to innovation is exemplified in their 3D printed shoes, which are redefining the boundaries of athletic footwear. The Vaporfly Elite Flyprint is a prime example of this, featuring a 3D printed upper that is lighter and more breathable than traditional fabrics. This shoe represents a leap forward in performance design, offering athletes a competitive edge through its precision-engineered fit and reduced weight.

Image Source: Nike

3. Dior Carlo Oxford

Dior’s foray into 3D printed footwear marks a significant milestone in the luxury fashion industry. The brand’s innovative approach is showcased in its latest 3D printed shoes, part of the Fall/Winter 2023 collection. These shoes are a modern reinterpretation of Dior’s classic Carlo model, transformed through high-tech design and manufacturing processes.

They are crafted with a textural lattice-like surface, offering a visually solid yet ultra-lightweight experience. The design team at Dior utilized 3D scanning to capture the essence of the Carlo Derby shoe, applying a digital texture that enhances both the aesthetic and tactile qualities of the footwear.

Image Source: Dior

4. Aliveform 3D Printed Future Footwear

Aliveform is redefining the future of footwear with its innovative 3D printed shoes, blending sustainability with cutting-edge design. Established in 2022, the Japanese label Aliveform has quickly made a name for itself with its print-to-order methods and use of natural materials. The brand’s ARMIS collection, featuring designs like the Armis Low, Low+, Mid, and Slide, showcases skewed linear structures that give the impression of motion, embodying the brand’s “Nature x Future” theme.

Image Source: Aliveform

5. SCRY 3D Printed Shoes

SCRY is reimagining footwear with its avant-garde 3D printed shoes, blending art and technology to create a futuristic aesthetic. The brand’s offerings, such as the SCRY × Sankuanz Bones “Shadow” and the SCRY Shuttle “Shadow,” are wearable sculptures that challenge traditional design norms.

The SCRY × Sankuanz Bones “Shadow” is a symbol of the brand’s philosophy of “Symbiosis and Coexistence,” featuring a design that symbolizes new life emerging from chaos. The shoe’s sharp lines and intricate patterns are produced using HALS printing technology, which provides a balance between form and support.

The SCRY Shuttle “Shadow,” on the other hand, is the brand’s first 3D printed model, showcasing a one-piece contoured design in a sleek black tone. It’s defined by dynamic lines and perforations, offering a glimpse into the potential of 3D printing in creating zero-waste resources and promoting social consciousness through sustainable practices.

SCRY’s collaboration with HELIOT EMIL for the “Digital Embryo” footwear collection further cements its position as a pioneer in 3D printed fashion. The collection’s boots, made from plastic-based polyurethane materials, embody a “Solitary Uniform” that eliminates harmful waste, marrying functionality with high fashion.

Image Source: SCRY

6. Zellerfeld 3D Printed Footwear

Zellerfeld is pioneering a new chapter in footwear with its 3D printed shoes, merging technology with eco-conscious practices. The brand's philosophy, "Printed, not made," encapsulates its innovative approach to shoe manufacturing. Zellerfeld shoes are custom-fitted, created from a smartphone scan of the buyer's feet, ensuring a perfect fit for every individual.

The shoes are crafted entirely from thermoplastic polyurethane, a single material that simplifies the recycling process. This commitment to sustainability is evident in Zellerfeld's closed-loop production model, where shoes can be returned and recycled into new designs at the end of their lifecycle.

Image Source: Zellerfeld

7. FUSED Footwear

FUSED footwear is redefining the shoe industry with its fully 3D-printed shoes, offering a unique blend of style, comfort, and sustainability. Each pair is crafted as a single piece, eliminating the need for stitching or gluing, which often leads to waste and inefficiency. The brand’s innovative use of thermoplastic elastomer (TPE) filament not only provides flexibility and durability but also allows for the shoes to be fully recycled, aligning with the company’s eco-friendly ethos.

The FUSED footwear collection includes a variety of models, such as the sleek FUSED Kodo, the versatile FUSED Oki, and the stylish FUSED Gaiba, each designed with a distinctive aesthetic and functional appeal. The shoes feature shock-absorbing lattice structures in the outsoles, ensuring a smooth and comfortable ride.

Image Source: FUSED Footwear

8. Koobz 3D Printed Shoes

Koobz's mission is to democratize access to footwear production by leveraging automation and 3D printing technology. Koobz eliminates the need for expensive hard tooling, such as molds, by using 3D printing, which reduces costs and simplifies the manufacturing process, making it more efficient and environmentally friendly.

Designed for both clubbing and everyday wear, Koobz shoes feature groovy, swirling printed lines that are not just aesthetically pleasing but also contribute to the shoes' softness and elasticity. Made entirely from recyclable thermoplastic polyurethane, these shoes offer both comfort and durability.

Image Source: Koobz

9. Hilos 3D Printed Shoes

With a vision to change how the world makes shoes, Hilos unites advanced technology with sustainable craft to produce exceptional, on-demand footwear. Their approach allows for intricate designs and a level of customization that traditional methods cannot match.

Hilos has developed a high-mix, low-volume supply chain for on-demand footwear, significantly reducing development times from the traditional 18 months to as little as 90 days.

Hilos’ collaboration with Ancuta Sarca at London Fashion Week 2024 showcased the first 3D printed heel combining harder nylons and softer TPU—both recycled and recyclable—within one assembly. This innovation opens up new design possibilities while maintaining the performance and comfort promised by 3D printing.

Image Source: Hilos

10. act'ble 3D Printed Dance Shoes

Act’ble is revolutionizing the world of dance with its 3D printed pointe shoes, designed to provide unparalleled comfort and performance. The Act’Pointes is a modular shoe system that perfectly fits the dancer’s feet, drastically enhancing health and performance.

The Act’Pointes feature a revolutionary sole crafted from high-performance materials, providing smooth foot rolling and easy relevées. This design reduces joint pressure and minimizes toe strain, allowing dancers to focus on their art without discomfort. The modular design means only worn-out parts need to be replaced, reducing waste and promoting a more sustainable approach to dancewear.

Image Source: act'ble

11. The Cryptide Sneaker

The Cryptide Sneaker, designed by Stephan Henrich, is a fully 3D printed shoe crafted to adapt to the wearer’s foot like a second skin, offering a unique blend of comfort and style. The sneaker is inspired by mythical creatures known as Cryptids, and true to its name, it leaves a distinctive footprint that captures the imagination.

Created using the Sintratec S2 system, The Cryptide Sneaker is laser sintered with flexible TPE material, allowing for a sole with an open design that is combined and printed together with an upper shoe that resembles a sock. This innovative approach results in a shoe that boasts multiple properties from a single material. By varying the wall thickness, Henrich has ingeniously created a sneaker that is both ergonomic and comfortable, with stiffer parts where necessary and soft, flexible areas for comfort.

Image Source: Sintratec

Make 3D Printed TPU Shoes at 3DSPRO

Utilizing Thermoplastic Polyurethane (TPU) materials with HP Multi Jet Fusion and SLS 3D printing technologies, known for their flexibility and durability, 3DSPRO can help you craft footwear that embodies comfort and resilience.

We firmly believe that 3D printing revolutionizes shoe manufacturing and offers a customizable, eco-friendly alternative to traditional footwear, paving the way for a new era in the fashion industry and encouraging responsible fashion choices.

COMMENTS

- Be the first to share your thoughts!